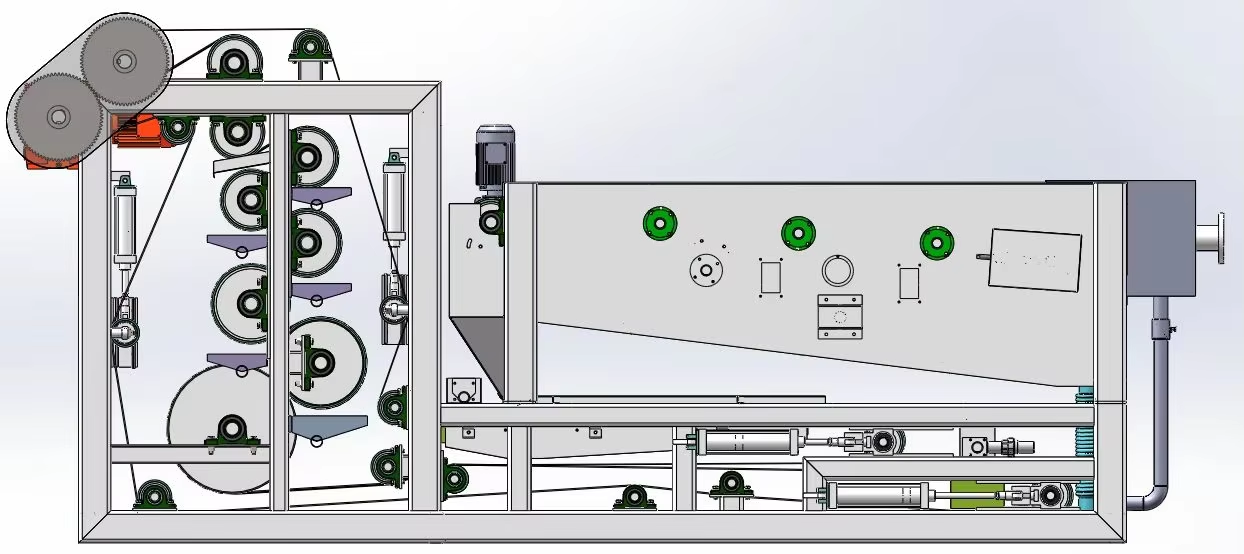

The belt filter (sometimes called a belt press filter, or belt filter press) is an industrial machine, used for solid/liquid separation processes, particularly the dewatering of sludges in the chemical industry, mining and water treatment. Belt filter presses are also used in the production of apple juice, cider and winemaking. The process of filtration is primarily obtained by passing a pair of filtering cloths and belts through a system of rollers. The system takes a sludge or slurry as a feed, and separates it into a filtrate and a solid cake.

Belt presses are a common type of mechanical dewatering equipment used to dewater most biosolids generated at municipal wastewater treatment plants and many industrial applications. Belt presses are used to remove water from liquid wastewater residuals and produce a non-liquid material referred to as “cake”. The Belt Filter Press is a broadly applicable product for dewatering municipal biosolids and industrial sludges. Since this is a continual process, it is effective on high-volume waste streams where a large production of low-quality filter cake is acceptable.

Belt filter technical sheet

| Sludge Kinds | Input Concentration % | Capacity m³/h | DS Capacity kg/h | Moisture of Cake % | PAM Consumption %(DP/DS) |

| Unconcentrated Aerobic Sludge | 0.5~1.5 | 15~30 | 150~300 | ~80 (+2) | 2~5 |

| Concentrated Aerobic Sludge | 2~4 | 6~12 | 200~300 | ~80 (+2) | 2~5 |

| Digested Sludge | 3~6 | 7~15 | 300~400 | <80 | 2~5 |

| Unconcentrated Primary Sludge | 0.8~2.0 | 18~35 | 300~400 | <80 | 2~5 |

| Concentrated Primary Sludge | 3~5 | 6~12 | 300~400 | <80 | 2~5 |

| Paper-making Activated Sludge | 0.5~2.5 | 15~35 | 200~400 | <78 | 3~7 |

| Printing and Dyeing Mixed Sludge | 1~3 | 10~25 | 180~350 | 75~78 | 3~10 |

| Model | Belt Width | Sludge Concentration | Outlet Concentration | Capacity | Power |

| DNT-1000 | 1000mm | 2-4% | 15-25% | 6-12 | 1.49kW |

| DNT-1500 | 1500mm | 2-4% | 15-25% | 12-15 | 2.05kW |

| DNT-2000 | 2000mm | 2-4% | 15-25% | 15-25 | 2.6kW |

| DNT-2500 | 2500mm | 2-4% | 15-25% | 35-50 |

4.1kW |

Belt filter press applications

High efficiency in specific applications: pulp & paper, manure, biogas, slaughterhouse, chemical sludge, etc.

Contact Us for a Consultation

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China