A belt filter press (BFP) provides sludge dewatering by pressing the sludge to force the water through a permeable medium. The process produces a cake (the dewatered product) having a dry solids (DS) content of 30% or more in the case of primary sludge. This is to be distinguished from the lower-energy gravity belt thickener process which achieves a maximum DS content of ~10%.

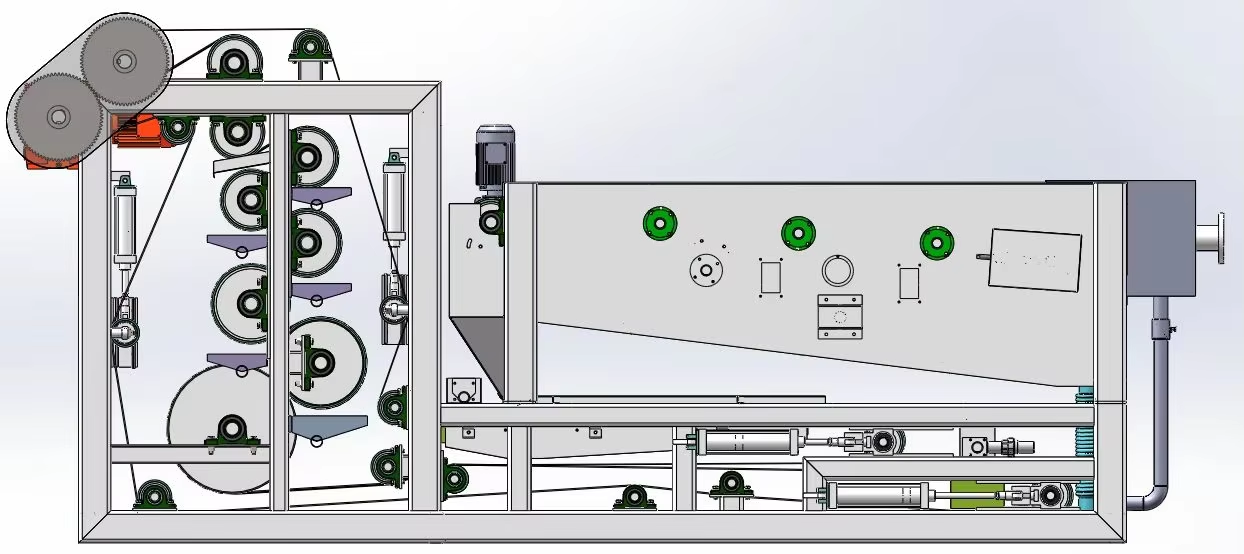

A BFP combines drainage and mechanical pressure sequentially to remove water. The equipment normally comprises 2−3 recirculating belts, with two belts combining at some point to compress the sludge and squeeze water from it.

Belt filter presses are manufactured as either two-belt or three-belt units. The current preference is that belt filter presses have three belts, which enables the gravity zone to operate independently from the pressing zones. Belt filter presses basically have three different zones:

■ gravity zone,

■ medium pressure zone (wedge zone), and

■ high pressure zone (shear zone).

Solids must be conditioned with polymer prior to being applied to a belt filter press. The polymer is used to release the water from the solids so that most of the water is removed on the gravity zone and additional water is then removed in the pressing zones. Approximately 60% to 70% of the water should be removed through the gravity zone with the remaining water removed in the wedge and shear zones.

Belt filter technical sheet

| Sludge Kinds | Input Concentration % | Capacity m³/h | DS Capacity kg/h | Moisture of Cake % | PAM Consumption %(DP/DS) |

| Unconcentrated Aerobic Sludge | 0.5~1.5 | 15~30 | 150~300 | ~80 (+2) | 2~5 |

| Concentrated Aerobic Sludge | 2~4 | 6~12 | 200~300 | ~80 (+2) | 2~5 |

| Digested Sludge | 3~6 | 7~15 | 300~400 | <80 | 2~5 |

| Unconcentrated Primary Sludge | 0.8~2.0 | 18~35 | 300~400 | <80 | 2~5 |

| Concentrated Primary Sludge | 3~5 | 6~12 | 300~400 | <80 | 2~5 |

| Paper-making Activated Sludge | 0.5~2.5 | 15~35 | 200~400 | <78 | 3~7 |

| Printing and Dyeing Mixed Sludge | 1~3 | 10~25 | 180~350 | 75~78 | 3~10 |

| Model | Belt Width | Sludge Concentration | Outlet Concentration | Capacity | Power |

| DNT-1000 | 1000mm | 2-4% | 15-25% | 6-12 | 1.49kW |

| DNT-1500 | 1500mm | 2-4% | 15-25% | 12-15 | 2.05kW |

| DNT-2000 | 2000mm | 2-4% | 15-25% | 15-25 | 2.6kW |

| DNT-2500 | 2500mm | 2-4% | 15-25% | 35-50 |

4.1kW |

Belt filter press applications

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China