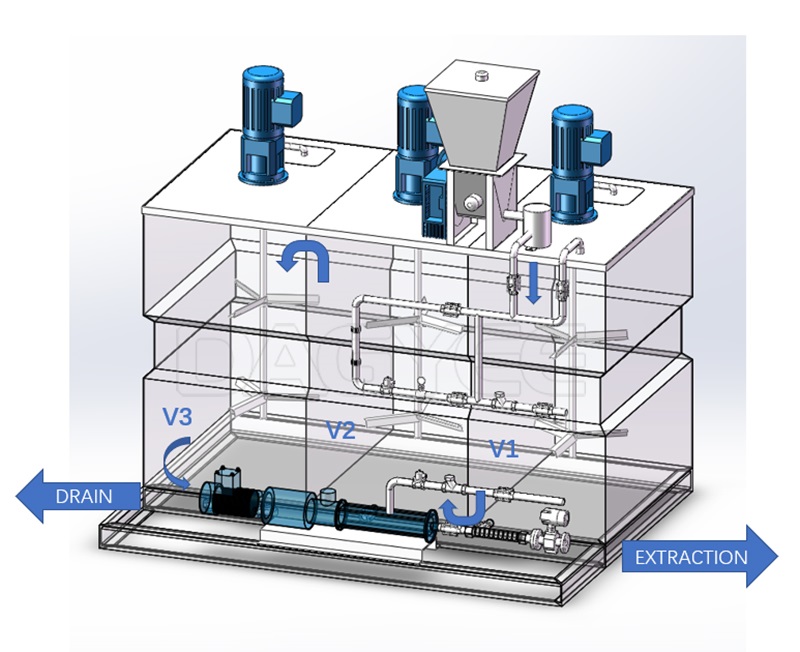

The DAGYEE unit provides automatic and continuous preparation of the polymer solution using a constant and uniform quality, resulting from:

One two-impeller mixer located in the preparation compartment (single impeller in the maturation compartment),

Optimized maturation cycles.

By fitting with an optional dilution unit, the main solution can then be diluted.

Polymer Dosing System has treee comparments. The first one is preparation compart- ment, the second one is ageing department and the last one is storage compartment. These three parts are seperated from easch orher by welded plates. Polymer Storage and feeding hooper is a steel small tank in which polyelectrolyte is stored. Polyelectrolyte in this hoop- er doses by the mounted feeding screw bottom of the hooper.

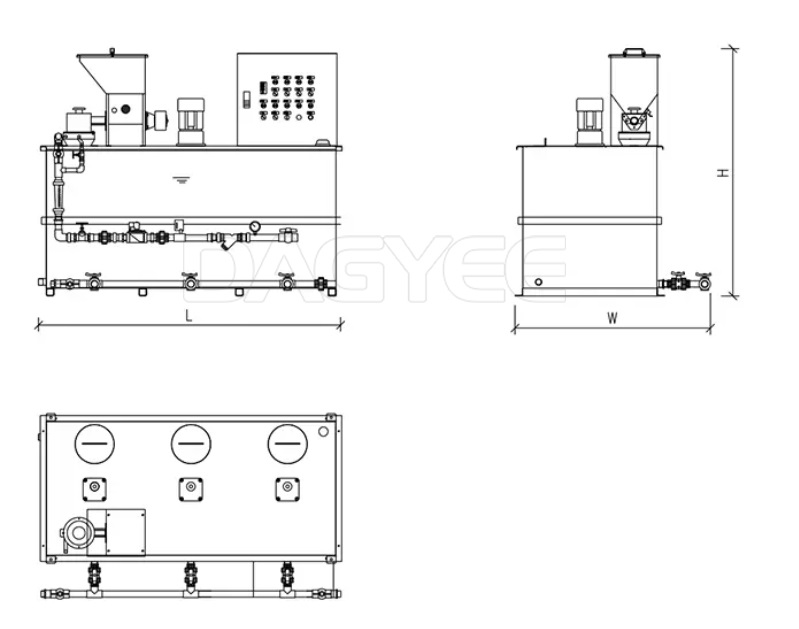

Polymer preparation unit model

| Model | Capacity L/H | Volume L | Timing H | Dimensions MM | Weight KG | Power KW |

|---|---|---|---|---|---|---|

| DT300 | 300 | 450 | 0.6-1 | 1500*1000*500 | 300 | 1.8 |

| DT500 | 500 | 750 | 0.6-1 | 1500*1000*650 | 420 | 1.8 |

| DT1000 | 1000 | 1500 | 0.6-1 | 2000*1000*900 | 500 | 2.8 |

| DT1500 | 1500 | 2250 | 0.6-1 | 2000*1200*900 | 620 | 3 |

| DT2000 | 2000 | 3000 | 0.6-1 | 2500*1200*1000 | 800 | 3.9 |

| DT3000 | 3000 | 4500 | 0.6-1 | 3000*1500*1000 | 950 | 5.3 |

| DT5000 | 5000 | 7500 | 0.6-1 | 5000*1500*1000 | 1250 | 7 |

| DT10000 | 10000 | 15000 | 0.6-1 | 4800*1800*2000 | 3600 | 7 |

Considerable savings in terms of polymer usage and running costs

Precision in the preparation and batching stages, optimising the processes

Mixing properties adapted to specific needs of the process

Space saving and system centralisation

Well controlled hydraulic retention and contact times

Consistent high-quality flocculant solution

The raw material dosing is linked to water flow to ensure that the final flocculant concentration remains constant.

Prevents unnecessary over-dosing

Dosing is linked to incoming waterflow.

Optimal design

Separate sections for make-up, maturation and solution storage.

Clot prevention

The end of the dosing auger is heated to prevent flocculant granulate from absorbing moisture from the air.

Polymer preparation unit application

Using polymers and flocculants considerably facilitates the processes of removing particles and solids suspended in liquid in the fo lowing applications:

• Treating potable and industrial processing water

• Purifying waste water

• Treating sludge, in order to improve the performance of centrifuges and filter presses

• Processes for the paper, chemical, petrochemical, mineral processing, canning industries

Contact us:

Company: Wuxi Dajiang Environmental Technology Co., Ltd. DAGYEE

Phone/WhatsApp:+8613961861780

Email: info@dagyee.com

Website: www.dagyee.com

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China