Externally rotary fed drum screen description

This stainless steel wedge wire screen is self-cleaning by nature due to constant back washing.

This often allows for only intermittent use of the spray bar cleaning system, reducing water usage.

Not well suited for fine screening of high flows, but the use of the doctor blade system makes this mechanical screen well suited when oils and grease are present.

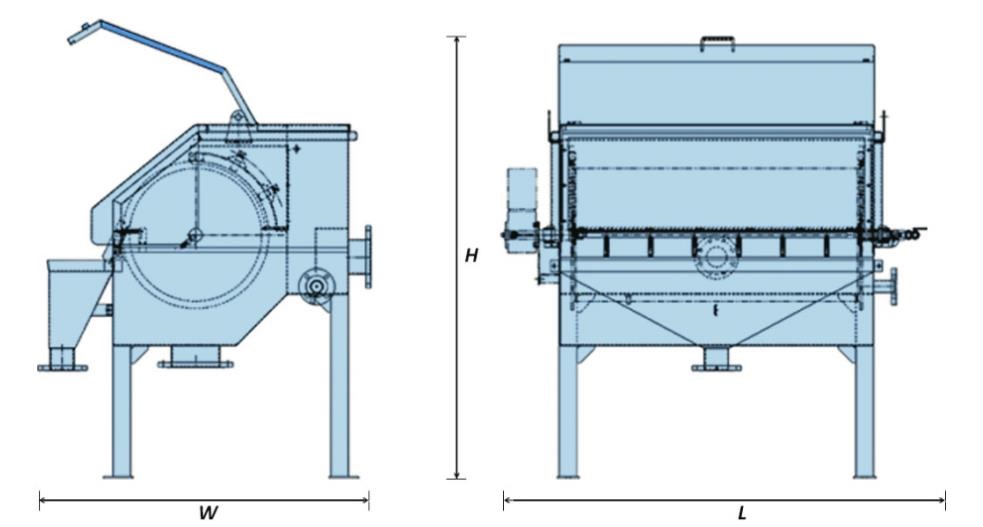

Sized based on peak flow, solids and fats, oils, grease loadings in the wastewater/process water, these units can be configured with a variety of piping scenarios, overall dimensions and slot openings.

Bypass configurations allow for bypass of overflow when upset conditions occur.

Externally rotary fed drum screen function

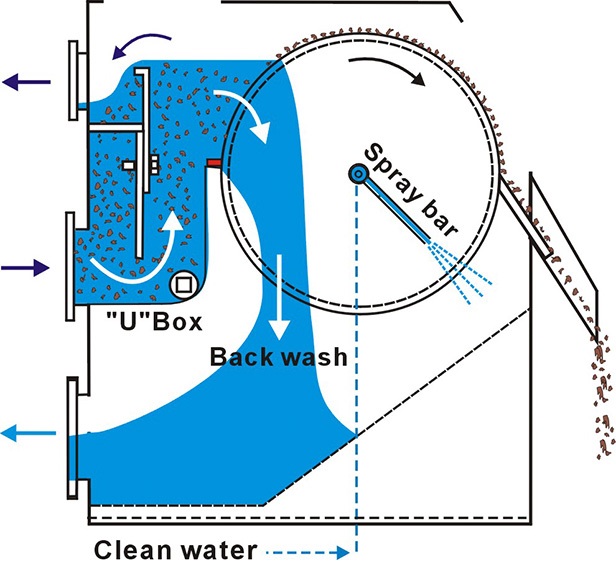

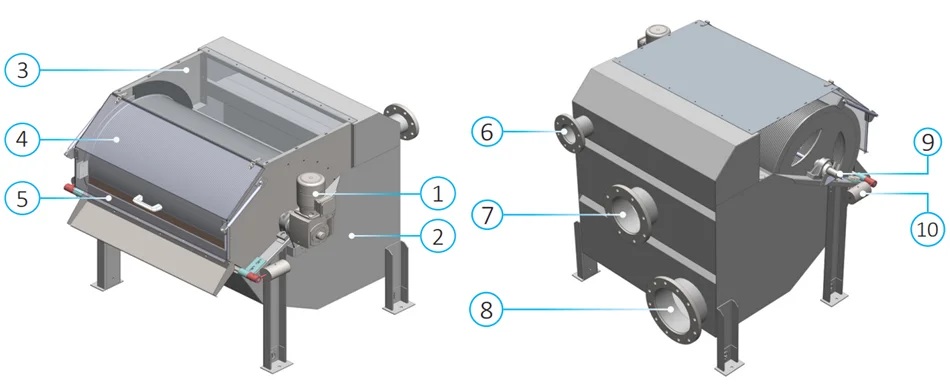

The equipment is composed of rotating drum, driving mechanism, unloading mechanism, recoil pipeline, sealing assembly, inspection door assembly, tank body, slag hopper, etc.

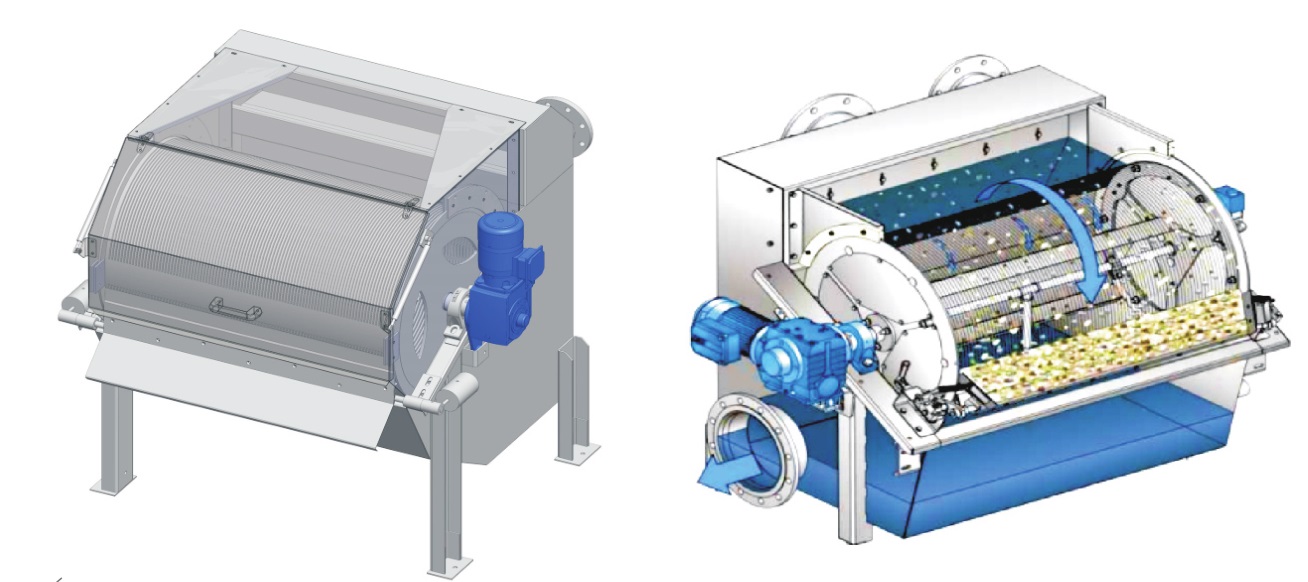

Working process: Sewage (or other raw water) flows from the front of the drum, through the drum, into the drum, and flows out from the bottom.

The suspended solids in the sewage stay on the rotating drum.

With the rotation of the drum surface, the trapped dirt is sent from the water inlet end to the discharge end on the other side, and is shoveled down by the discharge mechanism.

Externally rotary fed drum screen model

| Industry Type | Slot (mm) | RDS03/300 | RDS06/400 | RDS06/700 | RDS06/1000 | RDS06/1300 | RDS06/1600 | RDS08/2000 | RDS08/2500 |

|---|---|---|---|---|---|---|---|---|---|

| Paper Industry | 0.5 | 6 | 20 | 40 | 60 | 80 | 100 | 130 | 190 |

| Slaughter House | 0.5 | 4 | 15 | 30 | 45 | 60 | 75 | 95 | 130 |

| Seafood Industry | 0.75 | 5 | 17 | 35 | 50 | 70 | 90 | 110 | 140 |

| Meat Industry | 0.75 | 6 | 20.5 | 40 | 60 | 80 | 100 | 130 | 190 |

| Meat Industry | 1.0 | 7.5 | 25 | 50 | 75 | 100 | 125 | 150 | 220 |

| Vegetable Industry | 1.0 | 12 | 40 | 75 | 110 | 150 | 180 | 220 | 330 |

Externally rotary fed drum screen advantage

1. High Solids Removal Efficiency: Effective at removing a wide range of particle sizes

2. Continuous Operation: Can operate continuously with minimal operator attention.

3. Compact Design: Relatively small footprint compared to other screening technologies.

4. Versatility: Can be adapted to various applications and flow rates.

Externally rotary fed drum screen feature

1. Feed chamber with incorporated overflow.

2. Designed to allow sewage to cover the entire width of the cylinder.

3. Spillway blade made of wear-resistant material that exerts constant pressure on the cylinder.

4. Backwash by means of a device installed in the screening cylinder.

5. Spacing between 0.25 and 6 mm wedge wire or from 1 to 6 mm perforated.

6. Worm geared motor and helical gears.

Externally rotary fed drum screen application

Civil purification plants

Process of Water separation

Treatment of Industrial waste water such as;

1. Paper Mills

2. Food Industry

3. Chemical Industry

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China