Externally rotary fed drum screen description

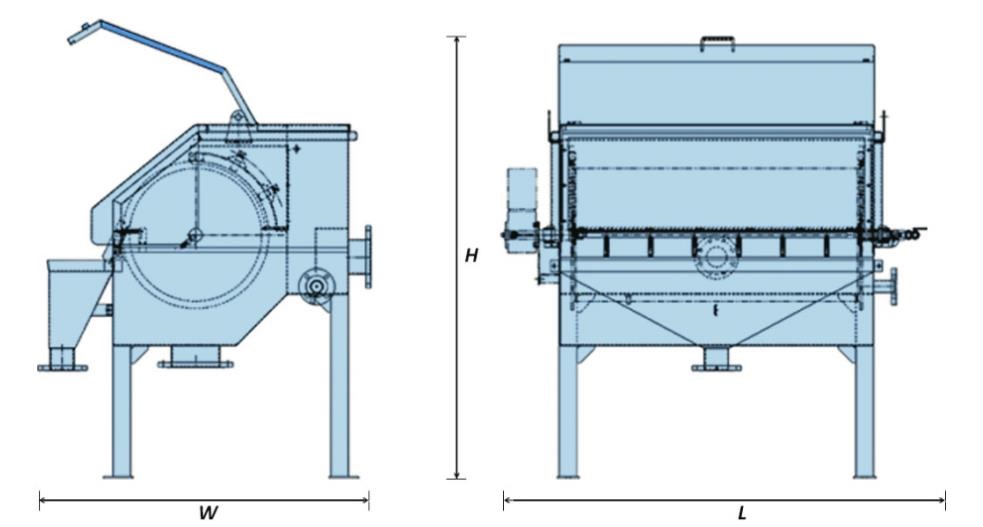

Externally-fed Rotary Drum Screens are individually designed to meet the client’s needs with regard to headbox configuration, inlets/outlets, height, width, pumped or gravity flow, etc.

All externally fed screens are equipped with overflow bypass provisions, located to suit the client’s needs, eliminating overflow concerns.

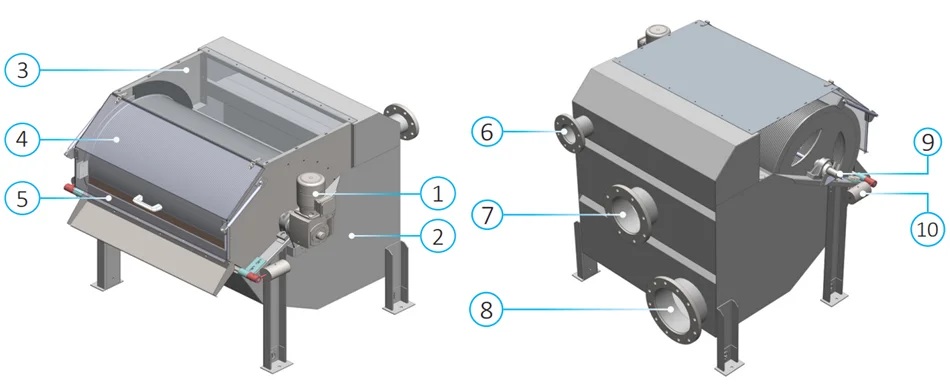

All stainless steel construction featuring a fully chassis legs, pans, and other extraneous parts with no hidden add-on costs.

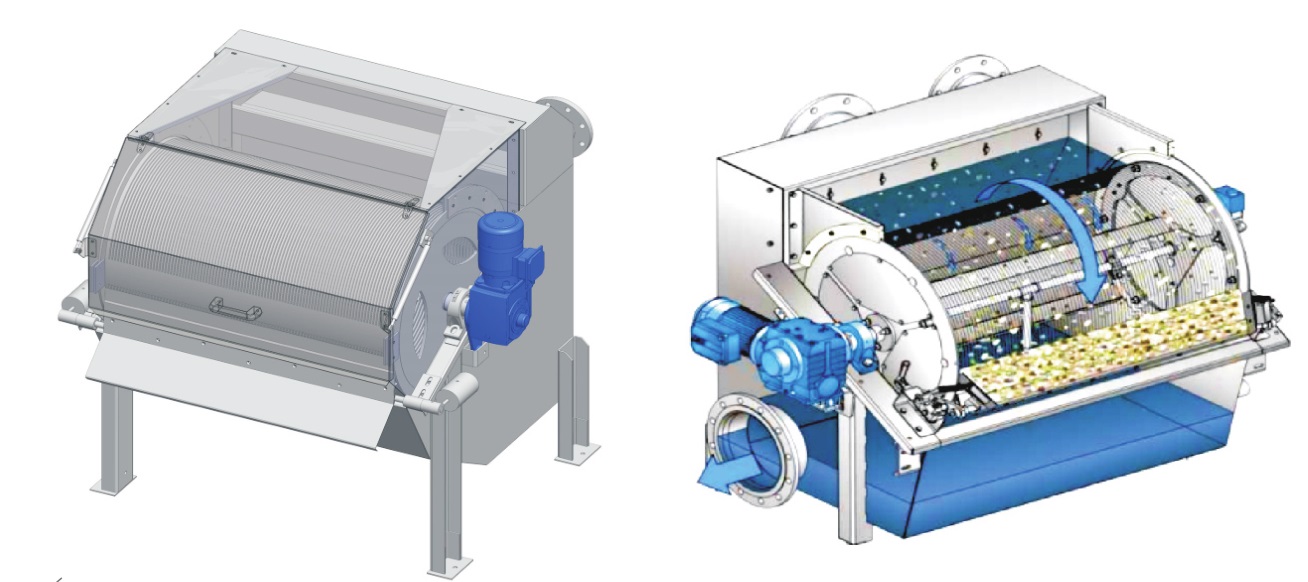

The wedge wire screen with variable slot opening provides solids removal based on client’s specific particle size distribution.

Each system is equipped with an integral sump which can be oversized and/or conformed to meet design and potential upset conditions.

Externally fed screens are equipped with high pressure, CIP able spray manifold systems which can be run automatically or with manual operation.

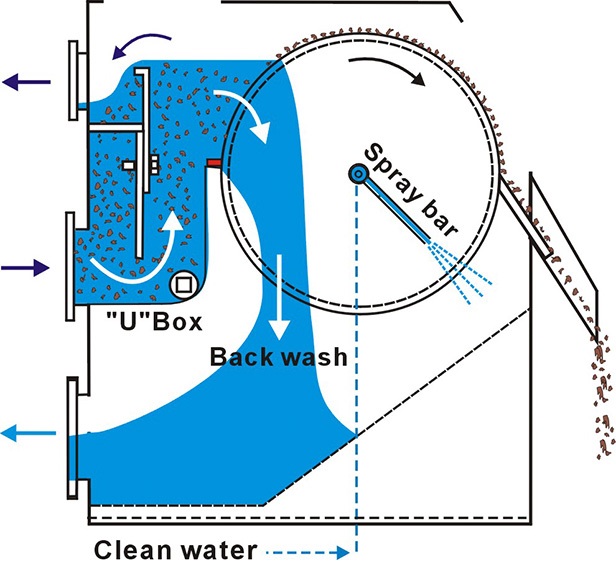

Externally rotary fed drum screen function

Externally Fed Rotary Drum Screens are equipment that separate floating solid substances in wastewater from water with the help of a screen.

They are used in industrial wastewater treatment plants as well as in domestic wastewater. In external fed rotary drum screens, the waste water taken into the feeding tank is filtered through a slowly rotating drum.

These types screens can be produced in different sizes according to the amount of suspended solid in the wastewater and the flow rate.

The discharge blade in front of the machine removes all the solid substances during the rotation and cleans the drum surface. The drum parts of the externally fed rotary drum screens can be manufactured from “wedge-wire” or perforated metal plates according to the size of the particles in the wastewater.

It can collect the solid particles between 0.25 and 3 mm. These collected screenings are approximately 50% of settleable solids in wastewater. Therefore, it also provides 10-15% BOD removal.

Externally rotary fed drum screen model

| Industry Type | Slot (mm) | RDS03/300 | RDS06/400 | RDS06/700 | RDS06/1000 | RDS06/1300 | RDS06/1600 | RDS08/2000 | RDS08/2500 |

|---|---|---|---|---|---|---|---|---|---|

| Paper Industry | 0.5 | 6 | 20 | 40 | 60 | 80 | 100 | 130 | 190 |

| Slaughter House | 0.5 | 4 | 15 | 30 | 45 | 60 | 75 | 95 | 130 |

| Seafood Industry | 0.75 | 5 | 17 | 35 | 50 | 70 | 90 | 110 | 140 |

| Meat Industry | 0.75 | 6 | 20.5 | 40 | 60 | 80 | 100 | 130 | 190 |

| Meat Industry | 1.0 | 7.5 | 25 | 50 | 75 | 100 | 125 | 150 | 220 |

| Vegetable Industry | 1.0 | 12 | 40 | 75 | 110 | 150 | 180 | 220 | 330 |

Externally rotary fed drum screen advantage

1. Significantly reduce the processing load of the wastewater system;

2. Stable and reliable work, low maintenance cost;

3. The wedge-shaped drum surface is especially suitable for the passage of fluid and is not prone to blockage;

4. The whole machine is made of high-quality stainless steel, which will never corrode;

5. Capable of automatic continuous operation and automatic unloading of slag;

6. Adopting a drum-shaped design and a large filtering area, so when the same processing capacity is used, the structure is compact, the area is small, and the energy consumption is low;

7. Fully enclosed design to prevent possible secondary pollution.

Externally rotary fed drum screen feature

1. Wedge-shaped as the filter parts, No clogging;

2. Stainless steel 304 316L;

3. Used for high temperature and high concentration liquid;

4. Drum-shaped design with a large filtering area, the floor space is small, and the energy Consumption is low;

5. The equipment uses the recoil nozzle to clean the clogged dirt in the grid.

6. Automatically and continuously running, and can automatically discharge slag.

7. Fully enclosed design to prevent secondary pollution during working time.

Externally rotary fed drum screen application

Sewage treatment plants

Vegetable, fruit processing industry

Sugar industry

Meat and poultry processing

Fish and shellfish processing industry

Brewing, malting and beverage industry

Horticulture industry

Industrial process water

Textile industry & laundries

Paper and pulp industry

Exhaust gas cleaning

Waste recycling industry

Bioenergy industry

Drinking water plants

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China