Externally rotary fed drum screen description

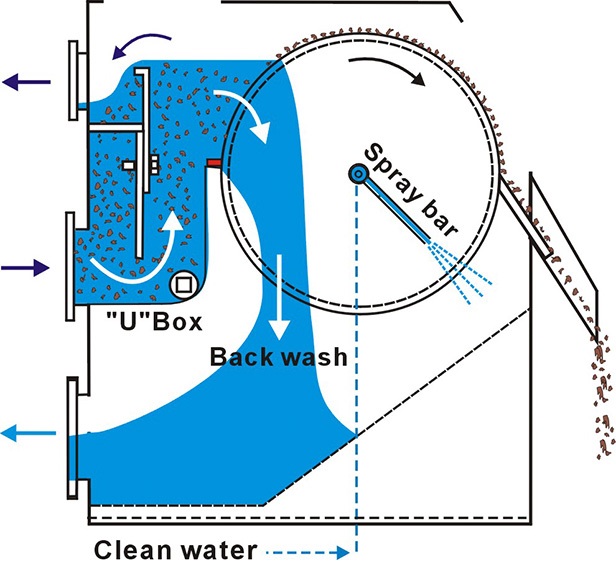

It utilizes gravity to evenly distribute influent flow across the externally fed rotating drum, effectively managing variations in solids concentration.

This controlled distribution enhances solids separation and reduces the risk of overload, maintaining reliable performance even with changing wastewater conditions.

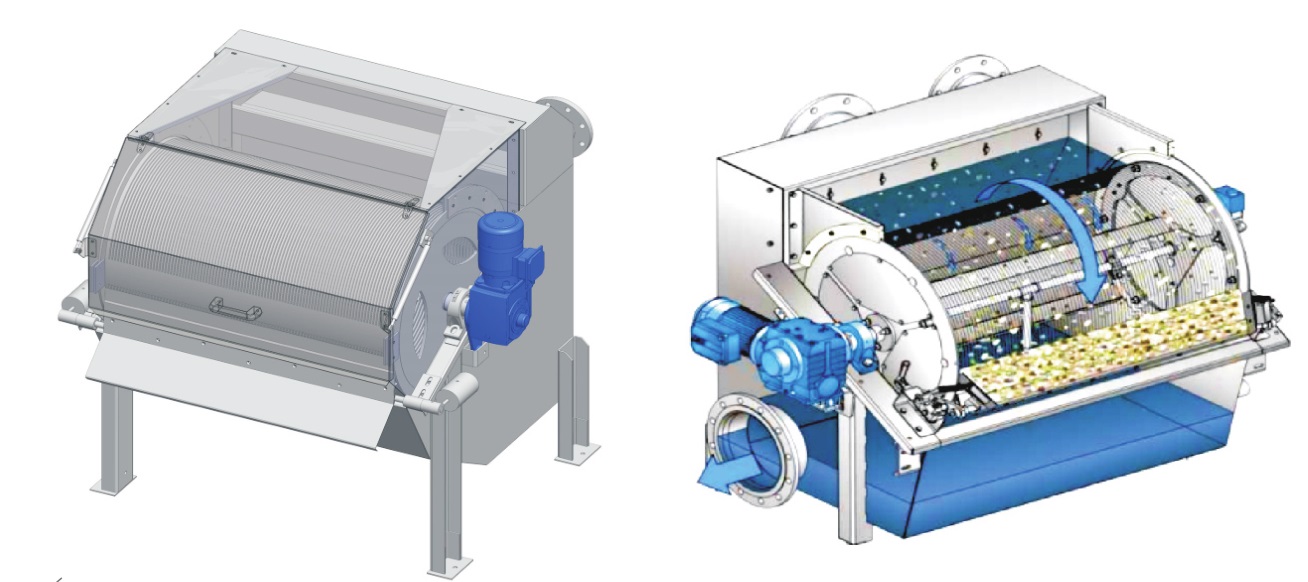

Drum rotation, combined with a precision spray cleaning system, eliminates buildup and maintains optimal screening efficiency without manual cleaning.

This external-feed design simplifies maintenance by ensuring solids remain on the drum's outer surface, protecting internal components from debris and wear.

The screened effluent moves swiftly downstream, minimizing headloss and enhancing overall system efficiency.

Externally rotary fed drum screen function

Rotation starts with the signal comes from submersible or centrifugal feeding pumps.

Nozzles start the injection of clean water to prevent from clogging.

Internally -fed drum screens capture fine particles in the drum then throw away the system by helezon.

Externally-fed drum screens stop fine particles out of the drum.

Treated water collects and transferred by the flanged outlet.

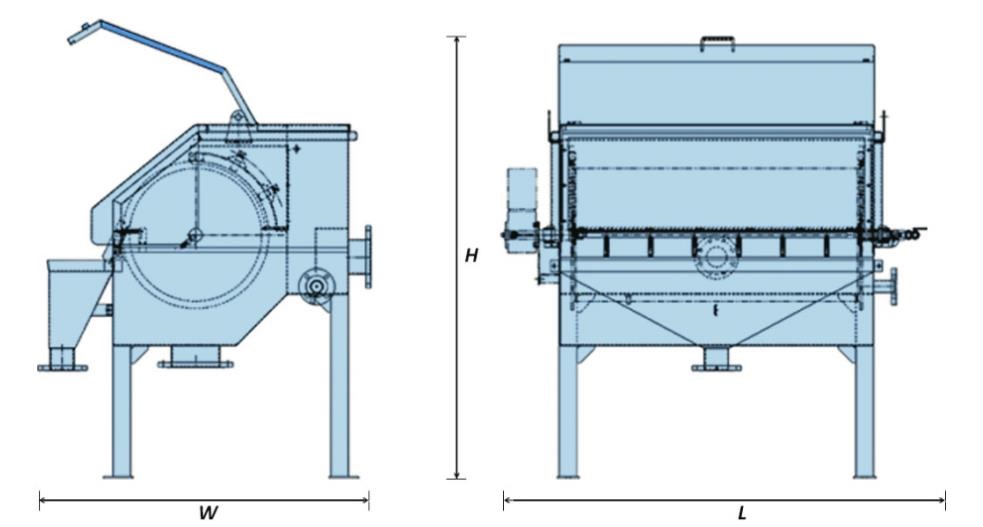

Externally rotary fed drum screen model

| Industry Type | Slot (mm) | RDS03/300 | RDS06/400 | RDS06/700 | RDS06/1000 | RDS06/1300 | RDS06/1600 | RDS08/2000 | RDS08/2500 |

|---|---|---|---|---|---|---|---|---|---|

| Paper Industry | 0.5 | 6 | 20 | 40 | 60 | 80 | 100 | 130 | 190 |

| Slaughter House | 0.5 | 4 | 15 | 30 | 45 | 60 | 75 | 95 | 130 |

| Seafood Industry | 0.75 | 5 | 17 | 35 | 50 | 70 | 90 | 110 | 140 |

| Meat Industry | 0.75 | 6 | 20.5 | 40 | 60 | 80 | 100 | 130 | 190 |

| Meat Industry | 1.0 | 7.5 | 25 | 50 | 75 | 100 | 125 | 150 | 220 |

| Vegetable Industry | 1.0 | 12 | 40 | 75 | 110 | 150 | 180 | 220 | 330 |

Externally rotary fed drum screen advantage

1. Free CAD or 3D drawing available.

2. Siemens or SEW motors to ensure the operation stability.

3. Schneider or Siemens control system with multi-language display.

4. Perfect after-sales service with maximum 1 year quality guarantee.

5. Can be customize according to filter media, filter precision and customer’s request.

6. Rich experience in all kind of applications to ensure every equipment can be fully used.

7. Independent research and Autonomous production of key component to ensure equipment quality.

Externally rotary fed drum screen feature

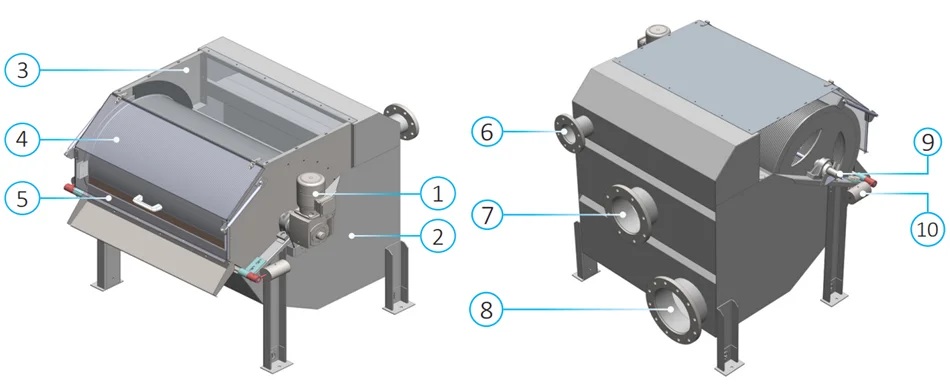

1. All 304 stainless steel construction.

2. Headbox with overflow protection.

3. Solid unitary frame.

4. Wedgewire drum.

5. Doctor blade assembly with Monel blade.

6. Internal spray bar.

Externally rotary fed drum screen application

Wastewater In The Paper Mill

Leather Factory

Slaughterhouse

Brewing

Food Industry

Chemical Fiber

Textiles

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China