The elimination of solids from liquids requires the use of liquid or powder polymers. This is achieved with polymer preparation and metering systems. The experts in wastewater treatment at DAGYEE understand how to provide the efficient technology to implement this specialist application.

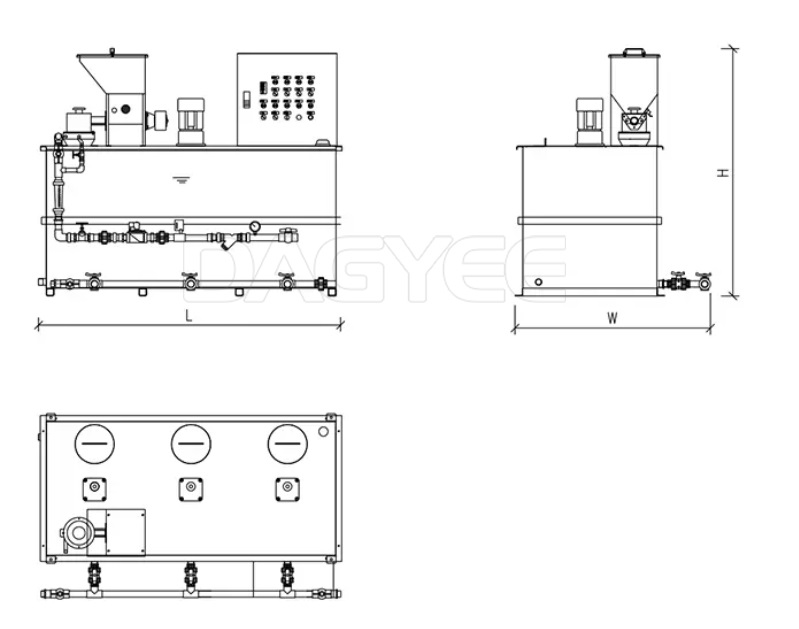

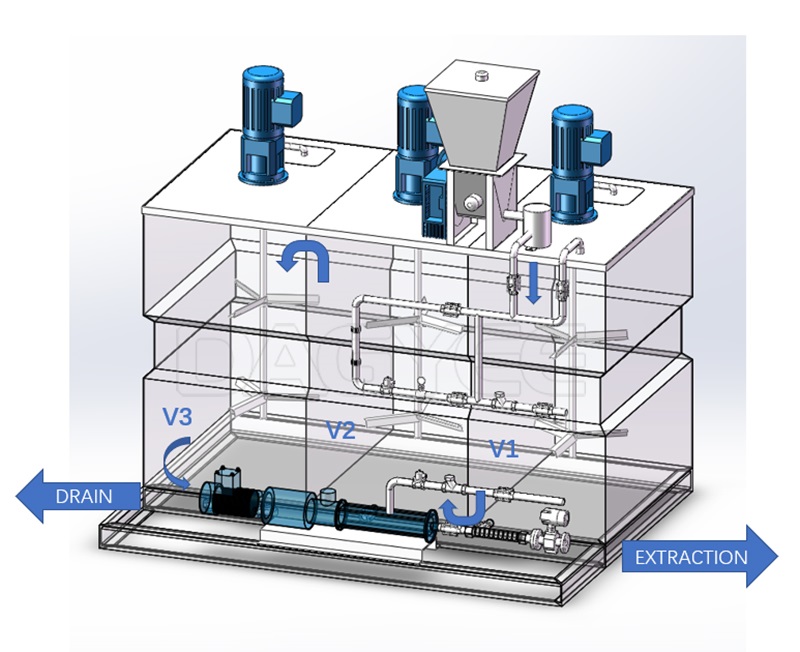

Polymer Dosing System has treee comparments. The first one is preparation compart- ment, the second one is ageing department and the last one is storage compartment. These three parts are seperated from easch orher by welded plates. Polymer Storage and feeding hooper is a steel small tank in which polyelectrolyte is stored. Polyelectrolyte in this hoop- er doses by the mounted feeding screw bottom of the hooper.

Polymer preparation unit model

| Model | Capacity L/H | Volume L | Timing H | Dimensions MM | Weight KG | Power KW |

|---|---|---|---|---|---|---|

| DT300 | 300 | 450 | 0.6-1 | 1500*1000*500 | 300 | 1.8 |

| DT500 | 500 | 750 | 0.6-1 | 1500*1000*650 | 420 | 1.8 |

| DT1000 | 1000 | 1500 | 0.6-1 | 2000*1000*900 | 500 | 2.8 |

| DT1500 | 1500 | 2250 | 0.6-1 | 2000*1200*900 | 620 | 3 |

| DT2000 | 2000 | 3000 | 0.6-1 | 2500*1200*1000 | 800 | 3.9 |

| DT3000 | 3000 | 4500 | 0.6-1 | 3000*1500*1000 | 950 | 5.3 |

| DT5000 | 5000 | 7500 | 0.6-1 | 5000*1500*1000 | 1250 | 7 |

| DT10000 | 10000 | 15000 | 0.6-1 | 4800*1800*2000 | 3600 | 7 |

High efficiency mixers: Provide a low flow mixing for a homogeneous flocculant polymerisation without mechanical deterioration.

Optimised process: Visual access to the process and alarms, fieldbus distributed control (optional) provides informative and easy to access equipment and status application updates, controlled costs.

1. Fully automatic operation including automatic dosing, dissolving and feeding

2. The highly precise dry polymer dosing device and the well-designed heater device can prevent the polymer from caking

3. The dosage of dry powder and water can be adjustable, so the solution with any concentration can be prepared

4. Optional: Vacuum feeding machine

5. Optional: on-line dilution system

6. Tank material: SS304 or SS316l, Polypropylene PP, FRP etc

Polymer preparation unit application

Sludge treatment conditioning and dehydration

Wastewater treatment plants

Municipal purification plants

Industrial purification plants

Agri-food industries

Beverage industries

Livestock farms

Meat processing

Fish processing

Paper industries

Textile industries

Contact us:

Company: Wuxi Dajiang Environmental Technology Co., Ltd. DAGYEE

Phone/WhatsApp:+8613961861780

Email: info@dagyee.com

Website: www.dagyee.com

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China