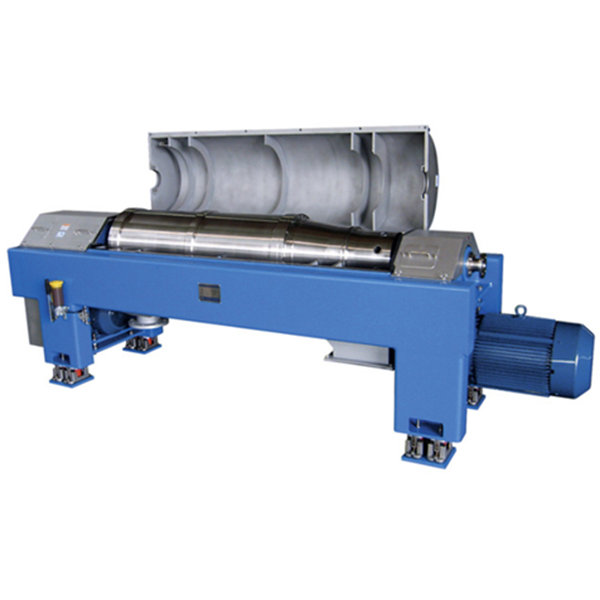

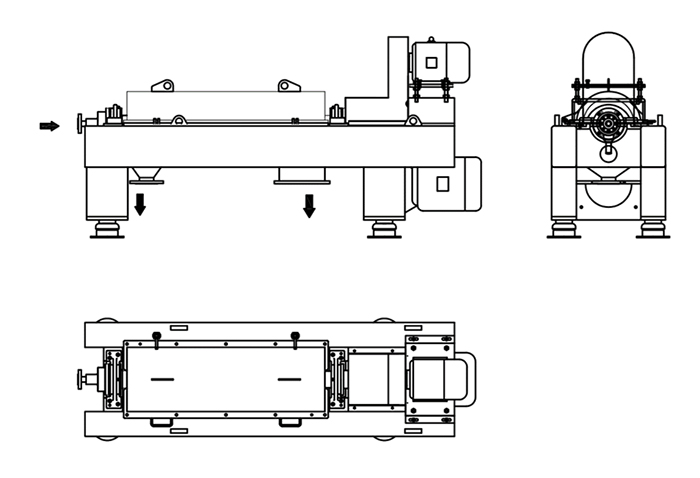

Solid Bowl Scroll Centrifuge Description

When solid/liquid mixtures with a high portion of solids need to be separated, decanter centrifuges are the solution of choice. In contrast to chamber filter presses, these solid shell scroll centrifuges or decanters operate continuously. High centrifugal forces separate the finely distributed solid particles from the suspension.

The modular design of our decanters makes them useful in a wide variety of industries throughout the world – from Australia to Zambia. The centrifuges are adapted optimally to the specific application. Applications range from sludge dewatering to classification or wet classification to the sorting of solids.

Solid Bowl Scroll Centrifuge Model

Model

LW250-900

250

900

5000

3500

0.5-3

11/5.5

LW350-1500

350

1500

3800

2850

1-5

18.5/5.5

LW400-1200

400

1200

3400

2581

1-8

22/7.5

LW400-1600

400

1600

3400

2581

2-10

22/7.5

LW400-1800

400

1800

3400

2581

2-12

22/7.5

LW450-1800

450

1800

3200

2572

5-20

30/7.5

LW450-2000

450

2000

3200

2572

5-25

30/7.5

LW530-2280

530

2280

2800

2350

10-50

45/15

LW600-2400

600

2400

2600

2265

15-65

55/18.5

LW650-2600

650

2600

2400

2100

20-80

55/90

LW720-2500

720

2500

2200

1950

25-90

75/90

LW800-2560

800

2560

2000

1800

30-100

90/132

LW800-3200

800

3200

2000

1800

30-110

90/132

LW900-3200

800

3200

1800

1650

30-150

132/200

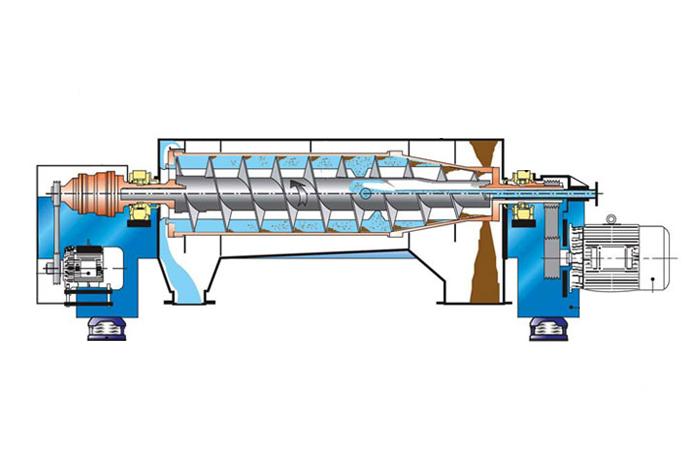

Solid Bowl Scroll Centrifuge Technical

The operating principle behind a solid bowl scroll centrifuge is elegantly simple yet incredibly effective:

The mixture (feed) enters through the central feed tube into the rotating bowl

Centrifugal force pushes heavier particles outward against the bowl wall

The screw conveyor continuously scrapes these solids toward the conical end

Clarified liquid flows toward the opposite end and exits through dedicated ports

Dried solids discharge through separate openings at the conical end

This continuous separation process happens at impressive speeds – typically between 3,000 to 4,000 RPM – creating centrifugal forces that can exceed 3,000 times gravity.

Solid Bowl Scroll Centrifuge Features

The Flottweg Simp Drive regulates the differential speed of the screw conveyor according to the load. If the differential speed is too low, there is a risk of blockage. With the correct setting, the system protects against overload and blockage. If the separation space is to be sealed against the atmosphere, Flottweg offers various sealing systems: atmospheric centrifuges, vapour-tight centrifuges, inert centrifuges. Various monitoring systems control vibration and speed. Critical operating conditions can thus be avoided and relevant safety standards complied with. Optionally, the storage temperature of the decanter centrifuge can also be monitored to prevent storage damage.

Avoidance of emissions to the environment or contamination of the product from the environment by means of closed construction design

protection against overload and blockage

Vibration, speed and temperature monitoring possible

Flottweg decanter centrifuges are continuously operating industrial centrifuges. Modern automation options reduce the effort needed to operate the system to a minimum. This means that our decanter centrifuges, which are used in the pharmaceutical, biotechnology and food industries, can be easily integrated into CIP systems. Monitoring the individual functions and the interaction of the individual components plays an important role in the automation of processes. Our new control interface InGo is easy to understand and shows the most important parameters at a glance. InGo was awarded the German Design Award 2018 in recognition of its ease of use. Our Simp Control safety and control module is also equipped with the InGo interface. Thanks to Simp Control, we can guarantee our customers worldwide identical global machine performance and safety technology.

minimal operator effort due to continuous and automatic operation

Integration into CIP systems possible

uniform and intuitive machine and system control

Solid Bowl Scroll Centrifuge Application

Decanter centrifuges have found their way into virtually every industry that requires separation technology. Let’s explore their most important applications:

Wastewater Treatment

In municipal and industrial wastewater treatment, decanter centrifuges play a crucial role in:

Sludge Dewatering: Reducing water content in sewage sludge by up to 80%, dramatically decreasing disposal volume and costs

Thickening Operations: Increasing solids concentration before further treatment

Phosphorus Recovery: Separating valuable phosphorus compounds for recycling

A medium-sized wastewater treatment plant processing 10 million gallons daily might recover 20-30 tons of dewatered biosolids through decanter centrifugation – material that can be composted or used for energy generation rather than sent to landfills.

Oil and Gas Industry

Decanter centrifuges serve as critical equipment in:

Drilling Mud Recycling: Removing drill cuttings from expensive drilling fluids for reuse

Produced Water Treatment: Separating oil, water, and solids from production streams

Oilfield Waste Management: Processing various waste streams to recover valuable components

One offshore drilling platform might process over 100,000 gallons of drilling mud daily through decanter centrifuges, recovering 95% of expensive base fluids while properly managing waste solids.

Food and Beverage Processing

From your morning orange juice to cooking oils, decanter centrifuges enable:

Fruit Juice Clarification: Removing pulp and particulates for clear juices

Vegetable Oil Extraction: Separating oils from seeds and fruits

Brewery Operations: Clarifying wort and recovering beer from tank bottoms

A large olive oil producer can process 5-10 tons of olives per hour using three-phase decanter centrifuges, simultaneously separating the oil, vegetable water, and solid pomace without chemical additives.

Chemical Processing

Chemical manufacturers rely on decanter centrifuges for:

Product Recovery: Capturing valuable solids or liquids from process streams

Catalyst Separation: Recovering expensive catalysts for reuse

Crystallization: Separating crystallized products from mother liquor

Pharmaceutical and Biotechnology

In the most demanding separation environments, decanter centrifuges provide:

Biomass Recovery: Harvesting cells or microorganisms from fermentation broths

Protein Precipitation: Separating precipitated proteins from solutions

API Recovery: Isolating active pharmaceutical ingredients

Mining and Minerals Processing

Decanter centrifuges handle challenging mineral separations including:

Coal Processing: Dewatering fine coal particles

Mineral Slurry Dewatering: Reducing moisture content in various mineral concentrates

Tailings Management: Processing mining waste for water recovery and volume reduction

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China