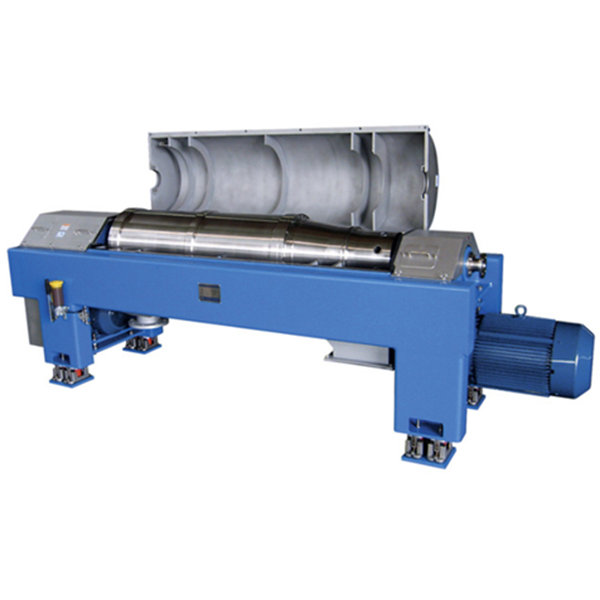

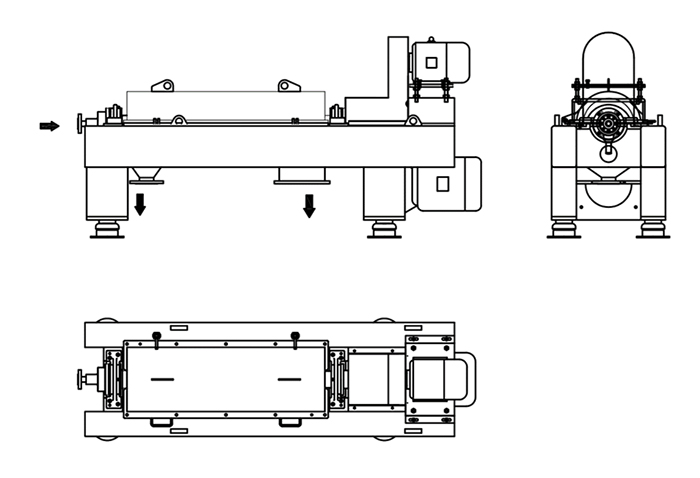

Decanter Centrifuges Description

A decanter centrifuge, also known as a horizontal bowl centrifuge, solid bowl centrifuge or scroll centrifuge, is a machine used to separate a solid material from a liquid(s) using a high-speed and continual rotational process. While wastewater treatment of biosolids is a primary application, the separation of one solid material from one liquid (2-phase dewatering) in a slurry is also important for a number of industries including chemical, food, oil, and mining to name a few.

2 Phase Decanter Centrifuges Model

Model

LW250-900

250

900

5000

3500

0.5-3

11/5.5

LW350-1500

350

1500

3800

2850

1-5

18.5/5.5

LW400-1200

400

1200

3400

2581

1-8

22/7.5

LW400-1600

400

1600

3400

2581

2-10

22/7.5

LW400-1800

400

1800

3400

2581

2-12

22/7.5

LW450-1800

450

1800

3200

2572

5-20

30/7.5

LW450-2000

450

2000

3200

2572

5-25

30/7.5

LW530-2280

530

2280

2800

2350

10-50

45/15

LW600-2400

600

2400

2600

2265

15-65

55/18.5

LW650-2600

650

2600

2400

2100

20-80

55/90

LW720-2500

720

2500

2200

1950

25-90

75/90

LW800-2560

800

2560

2000

1800

30-100

90/132

LW800-3200

800

3200

2000

1800

30-110

90/132

LW900-3200

800

3200

1800

1650

30-150

132/200

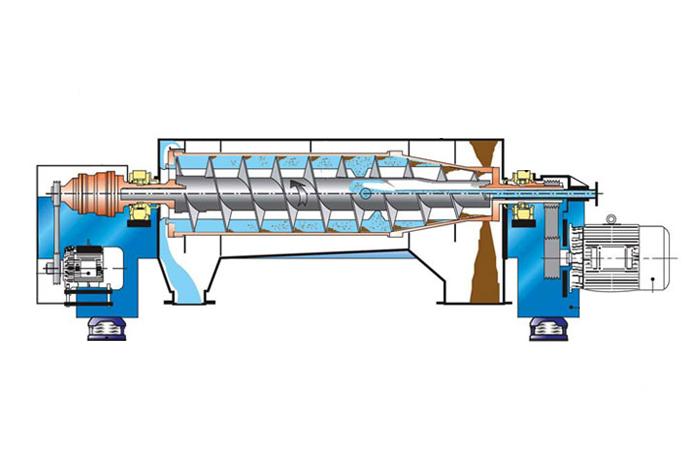

Decanter Centrifuges Structure

The typical decanter centrifuge consists of several key components:

Cylindrical Bowl: The main rotating vessel where separation occurs

Screw Conveyor (Scroll): A helical screw that rotates slightly faster or slower than the bowl to transport separated solids

Feed Zone: Where the mixture enters the centrifuge

Discharge Ports: Separate outlets for liquid and solid fractions

Drive System: Motors and gearboxes that power the rotation

Decanter Centrifuges Advantages

High-performance separation, resulting in high-value products and low waste management costs

Low energy consumption and carbon footprints

Low maintenance costs thanks to continuous operation, high-grade machine materials, smart design and well-thought preventive services

Low capital cost/capacity ratio

Decanter Centrifuges Application

Agriculture processing

Processing agricultural products efficiently and sustainably for a growing global population, against a backdrop of climate change, is the challenge facing the agricultural processing industry today. Alfa Laval is a world-leader when it comes to supporting companies in meeting this challenge with an extensive portfolio of equipment and many decades of experience. Whether it is producing sugar, starch and sweeteners for consumption or latex for textiles and medical use, Alfa Laval can help.

Latex processing

Alfa Laval has changed the game when it comes to latex processing. Alfa Laval’s world-leading technology is producing the highest quality dry rubber and latex concentrate.

Starch and Sweetener production

Alfa Laval is one of the world’s leading suppliers of process technology to the starch industry. For more than 80 years we have been helping starch producers across the globe stay ahead.

Sugar production

Sugar production is a thermally intensive operation, and whether it is beet processing, cane processing or sugar refining, energy saving is the key for producers who are looking to boost profitability.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China