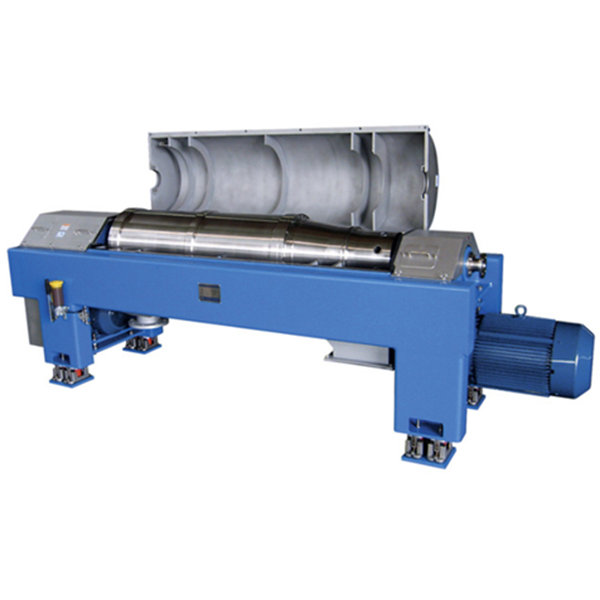

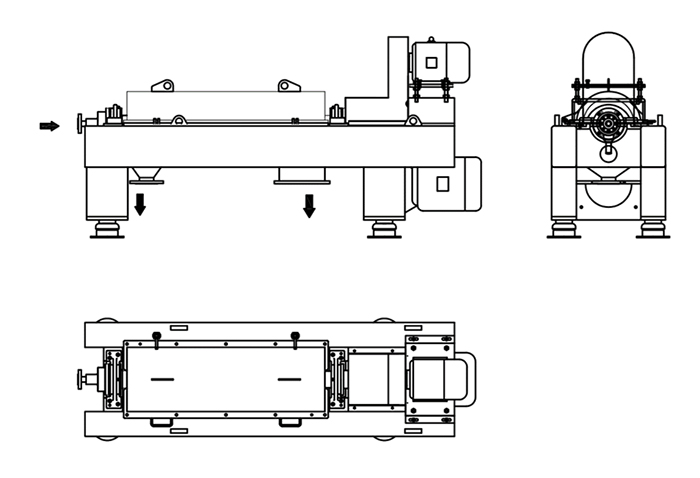

Horizontal Decanter Centrifuges Description

DAGYEE horizontal decanter centrifuges help you with solid-liquid separation within one single continuous process. Stand out from the competition with high performance separation that results in extracted/clarified products of excellent quality and higher commercial value. Make a difference as you recover valuable raw materials, reduce energy consumption and lower footprint and waste management costs with our industrial decanter centrifuge machines and services.

Horizontal Decanter Centrifuges Model

Model

LW250-900

250

900

5000

3500

0.5-3

11/5.5

LW350-1500

350

1500

3800

2850

1-5

18.5/5.5

LW400-1200

400

1200

3400

2581

1-8

22/7.5

LW400-1600

400

1600

3400

2581

2-10

22/7.5

LW400-1800

400

1800

3400

2581

2-12

22/7.5

LW450-1800

450

1800

3200

2572

5-20

30/7.5

LW450-2000

450

2000

3200

2572

5-25

30/7.5

LW530-2280

530

2280

2800

2350

10-50

45/15

LW600-2400

600

2400

2600

2265

15-65

55/18.5

LW650-2600

650

2600

2400

2100

20-80

55/90

LW720-2500

720

2500

2200

1950

25-90

75/90

LW800-2560

800

2560

2000

1800

30-100

90/132

LW800-3200

800

3200

2000

1800

30-110

90/132

LW900-3200

800

3200

1800

1650

30-150

132/200

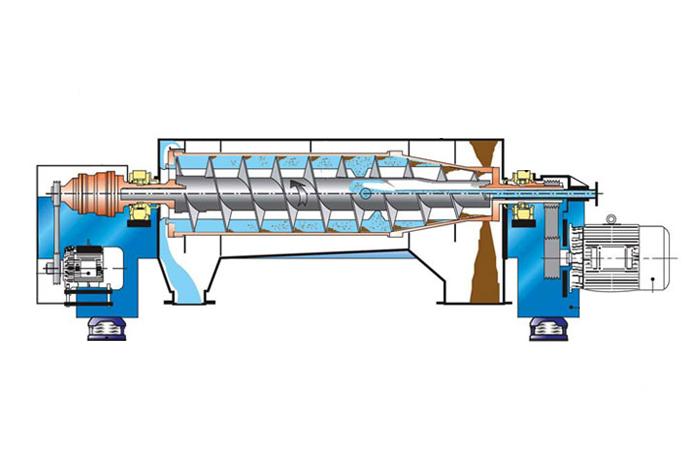

Horizontal Decanter Centrifuges Function

The separation of a solid and liquid(s) in a decanter centrifuge system work on the principle of gravitational forces. Whereas it takes considerable time for the gravitational separation of a muddy mixture (to fall to the bottom) and water (to rise to the top) in separation technologies based on 1xG separation such as,a static container, clarifier or lamal separator, the rapid rotation of a centrifuge greatly speeds up this gravitational principle.

In fact, the G-force generated by a decanter centrifuge can be well in excess of three-thousand times greater than gravity reducing the separation process from hours to mere seconds. Today's centrifuges are a counter-current type technology. The separation process in a 2-phase decanter centrifuge results in the denser solid particles to be compacted and settled out in the inner drum and then transported and removed via solids discharge end of the decanter. The centrate is routed to the opposite end of the centrifuge and removed via the centrate outlet. In a 3-phase centrifuge, the baffle system is built inside the centrifuge. The baffle system blocks the oil from being discharged with the water. The oil (the lighter phase fluid) is collected between the two baffles and skimmed off the top.

Horizontal Decanter Centrifuges Features

Our decanter centrifuges separate fine solids from a suspension and optimally clarify the separated liquid. The Simp Drive concept and the adjustable impeller make it possible to adjust the residence time of the mixture in the decanter bowl during operation. If the conditions at the inlet change, the separation result and solids content in the discharge always remain constant. Custom-made decanter centrifuge solutions for the individual processes of our customers This is the only way to achieve optimum separation results.

Separation of the finest solids from a suspension for an optimally clarified liquid phase (centrate)

Consistent separation results, thanks to automatically regulated differential speed and adjustable impeller

Custom-made solutions for the individual processes of our customers

Mechanical separation of liquids and solids with decanter centrifuges requires high forces. Abrasive materials or media with corrosive properties cause wear, abrasion and erosion. Flottweg offers a wide range of wear protection measures – always adapted to your application.

For all decanter components in contact with the product, Flottweg exclusively uses high-quality corrosion and acid resistant stainless steels. In addition there is a quality made in Germany. This makes our centrifuges particularly durable.

Depending on the requirements of our customers, we equip the decanter centrifuges with different lubrication systems. All lubrication systems allow the rotor bearings to be relubricated during operation.

The elimination of consumables (such as filter cloths and filter aids) additionally reduce maintenance and operating costs of our decanter centrifuges.

Costs are reduced because only wear parts are replaced

There are no consumables such as filter cloths, filter aids, etc.

Longer service life of the decanter

Various lubrication systems, e.g. automatic oil-air lubrication system for minimum oil consumption

Horizontal Decanter Centrifuges Application

Biotech and Pharmaceuticals

Chemicals

Energy and Utilities

Food and Beverage

Mining and Minerals, Pigment

Pulp and Paper

Steel

Water and Waste treatment

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China