PAM polymer preparation unit Description

Dissolved air flotation (DAF) is a water treatment process that clarifies wastewater (or other waters) by the removal of suspended matter such as oil or solids. The removal is achieved by dissolving air in the water or wastewater under pressure and then releasing the air at atmospheric pressure in a flotation tank or basin. The released air forms tiny bubbles which adhere to the suspended matter causing the suspended matter to float to the surface of the water where it may then be removed by a skimming device. Dissolved air flotation is very widely used in treating the industrial wastewater effluents from oil refineries, petrochemical and chemical plants, natural gas processing plants, paper mills, general water treatment and similar industrial facilities. A very similar process known as Induced Gas Flotation (IGF) and Dissolved Gas Flotation (DGF) are also used for wastewater treatment in the oil industry where atmospheric air is substituted with Nitrogen gas to reduce the risk of explosion. Froth flotation is commonly used in the processing of mineral ores.

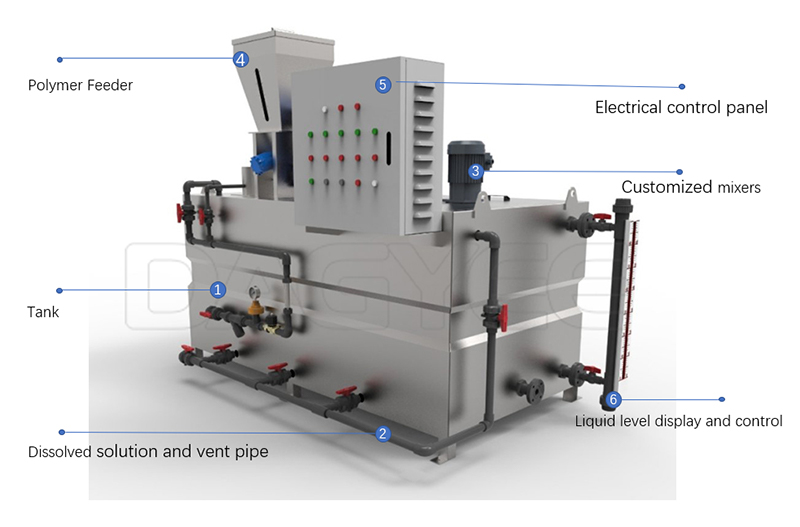

Polymer dosing device

Polymer dosing device is composed of hopper, push screw, electric heater and etc. The effective volume of the hopper can meet the dosage for a long time which is equipped with sight glasses for observing material level monitored by the dry powder level meter. The push screw driven by the high-precision reducer can satisfy the dosage. The electric heater can be installed in the discharge pipe of push screw, and it can prevent the powder from caking.

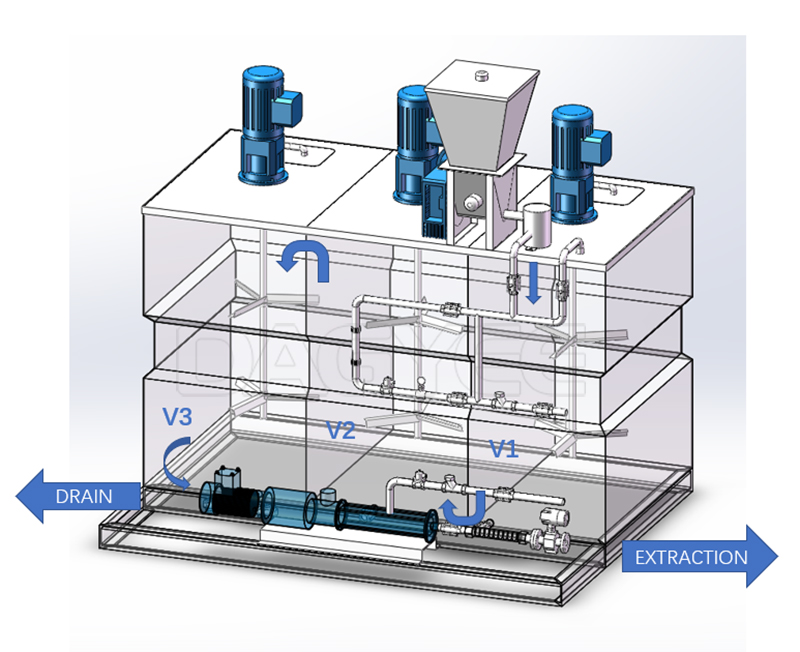

Polymer dissolving device

Polymer dissolving device is composed of pre-soaking device, tank, and 3 sets of mixers. The pre-soaking device is to infiltrate and mix the polymer powder in advance. The 3 tanks are precast mixing tank, homogeneous slaking tank and solution storage tank, in which there is a mixer correspond to guarantee the homogeneity.

Water supply device

Water supply device is composed of pipeline, manual ball valve, filter, pressure gauge, solenoid valve, stop valve, and the rotor flow meter, etc.

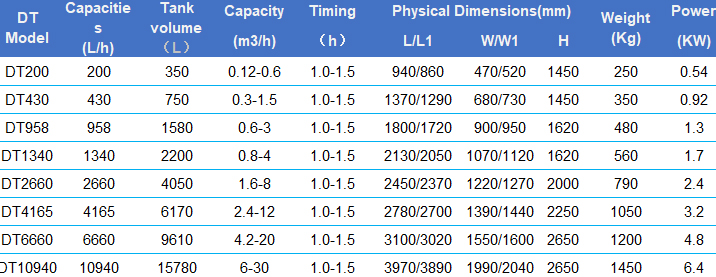

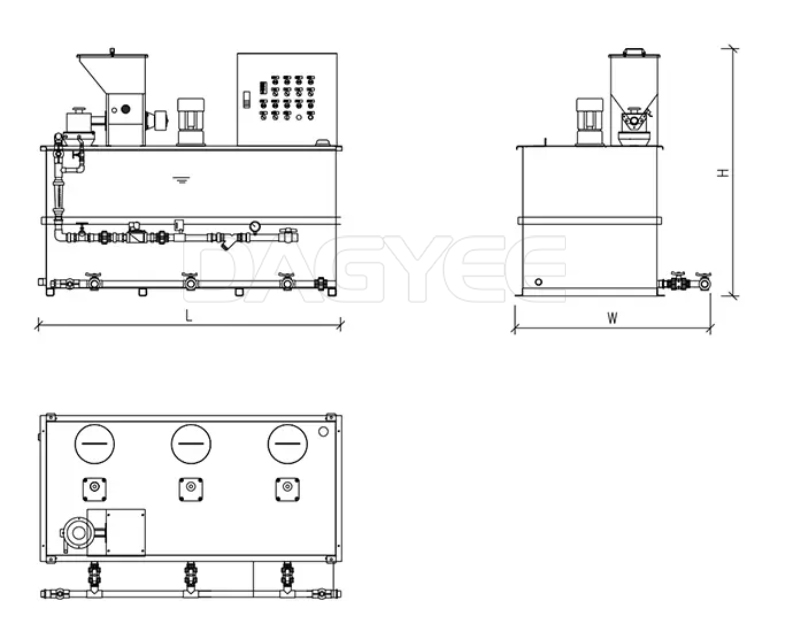

PAM Polymer Preparation Unit Model

PAM Polymer Preparation Advantage

DAF technology boasts an impressive removal efficiency, often exceeding 90% for suspended solids. This makes it a robust choice for industrial and municipal applications where high cleanliness standards are required. Additionally, its ability to adapt to varying wastewater characteristics ensures reliable performance across different scenarios.

The compact design of DAF units is another significant advantage. Compared to traditional gravity clarification, DAF systems take up less space, making them suitable for facilities with limited footprints. The ability to handle bulking solids and produce higher sludge solids content further distinguishes DAF technology in wastewater treatment.

Moreover, the multitude of applications, ranging from oil and grease removal to biosolids thickening, underlines the flexibility of DAF units. They prove effective in various treatment goals such as product recovery, pretreatment for sewer discharge limits, and polishing of biological treatment effluent.

PAM Polymer Preparation Application

1. Paper mills

Historically, paper mills represent one of the first applications of dissolved air flotation systems. Dissolved air flotation units are used in paper mills for two different applications. The main use is as a process machine: this system allows to recover most of the paper fibers that constitute the raw material and that would otherwise be lost with the cloth washing water.

Secondly, dissolved air flotation units are used for the purification treatment of wastewater, in particular for the removal of suspended solids and the COD linked to them. In both cases, the system is ideal for optimizing the solids recovery yield thanks to the effectiveness of its air dissolving system.

2. Confectionery industries

One of the main applications of the dissolved air flotation system is the pre-treatment of waste water in the confectionery industry. The different production lines are subjected to frequent washing both for hygiene reasons and when products with different characteristics are produced. The process water of the confectionery industry is characterized by high levels of suspended solids, COD and fats.

Dissolved air flotation systems, used as a pre-treatment upstream of a biological treatment, or before discharge into the sewer system, allow these parameters to be substantially reduced. This allows the size to be reduced and the operation of a possible biological plant downstream to be optimized. Alternatively, a lower polluting load allows companies to discharge their waste water into the sewer system within the values set by the most stringent regulations. The simplicity of management is such that it does not require specialized personnel to operate the system.

3. Cured meat factories

The water coming out of the sausage factories contains high levels of fats and suspended solids, deriving from the meat processing and stuffing process. The presence of these substances can create problems for the biological wastewater treatment plant. Fats inhibit the development of bacterial flora, and the high polluting loads require large-sized treatment plants with long residence times of the wastewater in the biological treatment tanks.

Flotation units intervene on both fronts. Used as a pre-treatment, it allows the removal of fats and suspended solids with extremely high efficiency, thanks to the innovative air dissolving system.

4. Primary and secondary clarification for biological plants

The dissolved air flotation system is widely used as a clarification phase in biological plants of all potentials. Thanks to its high efficiency in removing suspended solids, this solution is useful for the primary clarification of wastewater because it allows the use of extremely small spaces. The efficiency of solids removal is such as to drastically reduce the size of subsequent treatment phases.

For the same reasons, it is also used for secondary clarification, with an additional advantage. The sludge extracted from the flotation unit has a density approximately double that of the sludge extracted from a traditional sedimentation system. This allows for a reduction in the costs of sludge disposal or of creating any sludge treatment line. Furthermore, a denser sludge is recirculated, with obvious savings on the quantity of recirculation and consequently on the size of the oxidation tank.

5. Dairy industries

This is an application very similar to that of salami factories. In these companies, washing occurs very frequently and the waste water is rich in fats and highly biodegradable solid substances. The polluting load is very high and the treatment of this water requires the construction of large plants even when the flow rates involved are relatively low. The flotation unit, in this context, is widely used as a pre-treatment.

Its small size allows it to be installed even on existing plants or in any case where there are space problems. The dissolved air quickly brings solids and fats to the surface, without problems of bad odors and with extremely high removal efficiency. This allows the polluting load to be reduced and therefore the size of the entire plant. Flotation systems are often used even on existing plants that need to be upgraded.

6. Oil & gas industries

Oil depots and refineries are large-scale facilities. Rainwater and runoff water that falls on yards and buildings must necessarily be treated before being discharged. In addition to this, there is also the displacement and washing water in general. A peculiar characteristic of these waters is the presence of considerable quantities of oil. Dissolved air flotation units are effective solutions for their removal.

Flotation certainly has the advantages of removal efficiency, small dimensions, and the possibility of inserting the machine into the context of an existing plant. If the company already has its own biological purification plant, the system allows for an increase in efficiency by removing upstream all substances that could inhibit the correct functioning of the biological process.

7. Textile industries

The waters coming out of these companies are rich in fibers that escape from the various washing processes to which the raw wool is subjected. The raw material is rich in solids, fats and organic substances, which are removed with the washing waters. In the waters there are also abundant quantities of surfactants deriving from the detergents used for washing.

Dissolved air flotation systems have proven to be effective systems for the treatment of these waters, upstream of any biological and/or chemical-physical processes. They allow the removal of approximately 80% of the fats and solids contained in the waters, and also carry out a partial reduction of the surfactants linked to the latter. The micro air bubbles that are generated in the saturator and that are released in the flotation tank are so fine that they do not cause the formation of foam despite the high levels of surfactants.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China