PAM polymer preparation unit Description

Dissolved air flotation (DAF) is a water treatment process that clarifies wastewater (or other waters) by the removal of suspended matter such as oil or solids. The removal is achieved by dissolving air in the water or wastewater under pressure and then releasing the air at atmospheric pressure in a flotation tank or basin. The released air forms tiny bubbles which adhere to the suspended matter causing the suspended matter to float to the surface of the water where it may then be removed by a skimming device. Dissolved air flotation is very widely used in treating the industrial wastewater effluents from oil refineries, petrochemical and chemical plants, natural gas processing plants, paper mills, general water treatment and similar industrial facilities. A very similar process known as Induced Gas Flotation (IGF) and Dissolved Gas Flotation (DGF) are also used for wastewater treatment in the oil industry where atmospheric air is substituted with Nitrogen gas to reduce the risk of explosion. Froth flotation is commonly used in the processing of mineral ores.

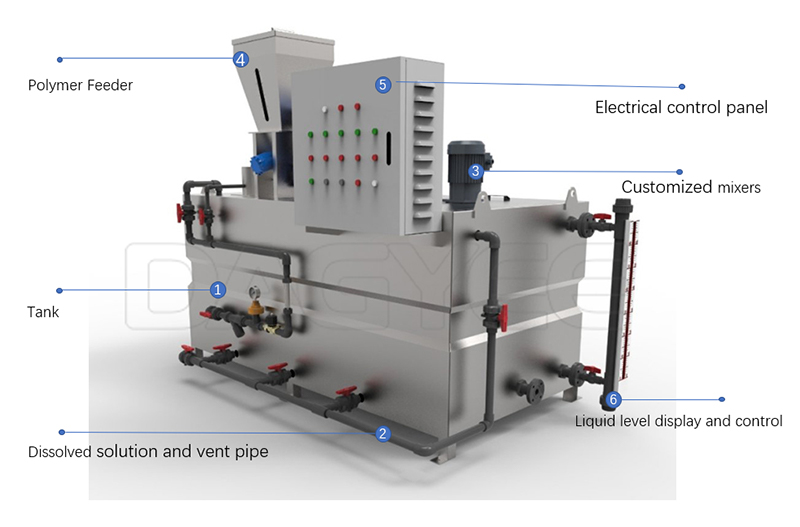

Polymer dosing device

Polymer dosing device is composed of hopper, push screw, electric heater and etc. The effective volume of the hopper can meet the dosage for a long time which is equipped with sight glasses for observing material level monitored by the dry powder level meter. The push screw driven by the high-precision reducer can satisfy the dosage. The electric heater can be installed in the discharge pipe of push screw, and it can prevent the powder from caking.

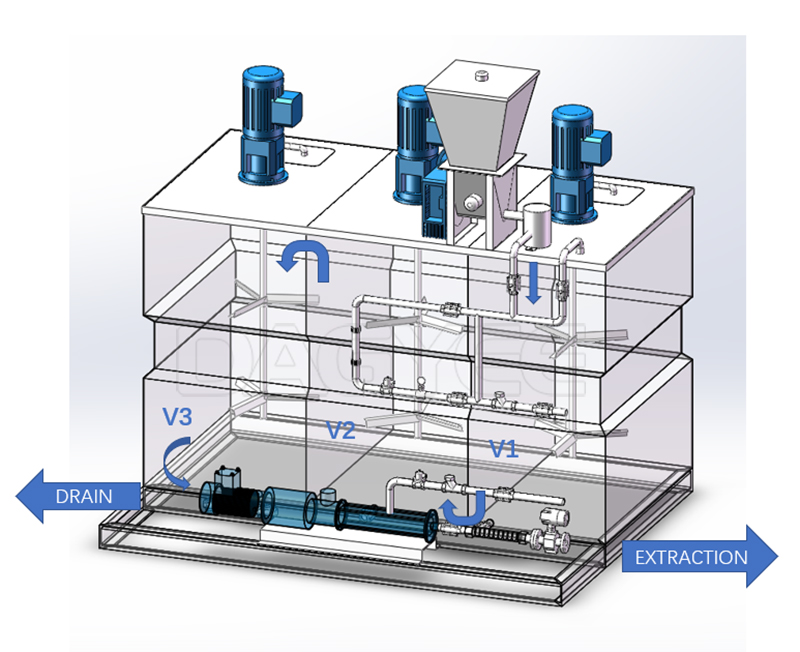

Polymer dissolving device

Polymer dissolving device is composed of pre-soaking device, tank, and 3 sets of mixers. The pre-soaking device is to infiltrate and mix the polymer powder in advance. The 3 tanks are precast mixing tank, homogeneous slaking tank and solution storage tank, in which there is a mixer correspond to guarantee the homogeneity.

Water supply device

Water supply device is composed of pipeline, manual ball valve, filter, pressure gauge, solenoid valve, stop valve, and the rotor flow meter, etc.

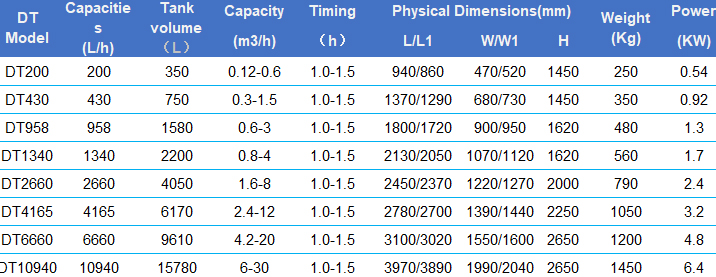

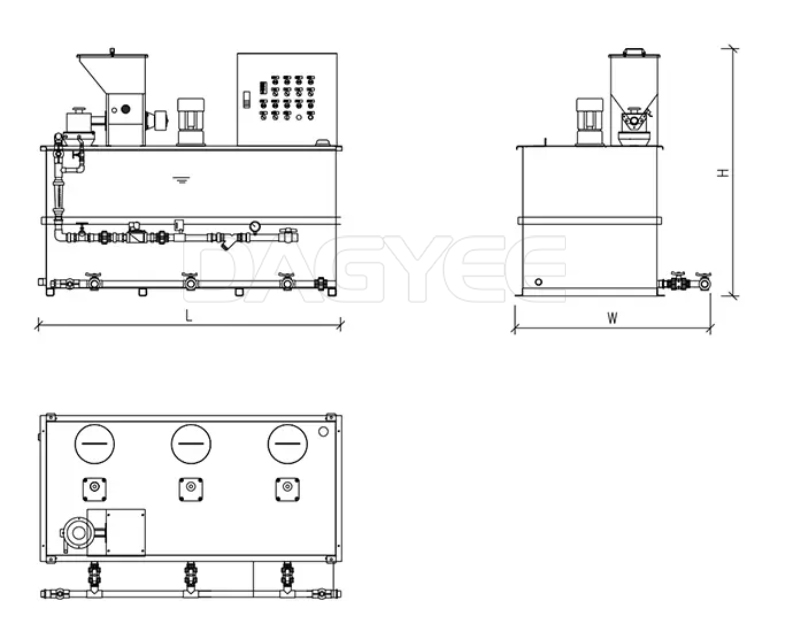

PAM Polymer Preparation Unit Model

PAM Polymer Preparation Function

The operational effectiveness of dissolved-air flotation processes can be largely attributed to the unique mechanism through which air bubbles facilitate the separation of solids from liquids. Initially, raw wastewater is introduced into a flotation tank, where it is pre-treated to prepare it for flotation. This pre-treatment commonly involves the addition of coagulants and flocculants, which help agglomerate fine particles into larger flocs.

Next, a high-pressure pump draws water from the flotation tank and saturates it with air, producing dissolved air at a concentration greater than it can hold at atmospheric pressure. Upon reaching the flotation chamber, pressure is released, and the excess air comes out of the solution, forming tiny bubbles that adhere to the suspended and colloidal particles within the wastewater. These adhered particles become buoyant and rise to the water's surface, forming a sludge layer that can be skimmed off. This mechanical method increases the overall efficiency of contaminant removal, resulting in treated water of higher clarity.

PAM Polymer Preparation Application

Dissolved air flotation systems are commonly used in the following industries and production processes.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China