PAM polymer preparation unit Description

Dissolved air flotation (DAF) is a water treatment process designed to remove oils, solids, and greases. In fact, the process helps clarify wastewaters – and other waters – by eliminating different types of suspended matter. The DAF process dissolves air in the water under pressure – then releases it at atmospheric pressure. The dissolved air flotation process takes place in a tank basin, which is ideal for catching and eliminating suspended matter. In fact, the released air creates tiny bubbles, which conform to the suspended matter and cause it to rise to the surface. Skimmers or a similar device then eradicate the substance.

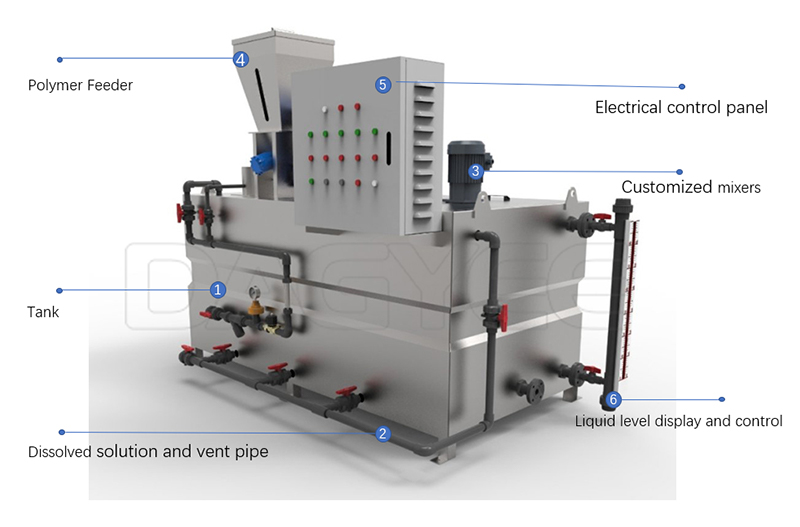

Polymer dosing device

Polymer dosing device is composed of hopper, push screw, electric heater and etc. The effective volume of the hopper can meet the dosage for a long time which is equipped with sight glasses for observing material level monitored by the dry powder level meter. The push screw driven by the high-precision reducer can satisfy the dosage. The electric heater can be installed in the discharge pipe of push screw, and it can prevent the powder from caking.

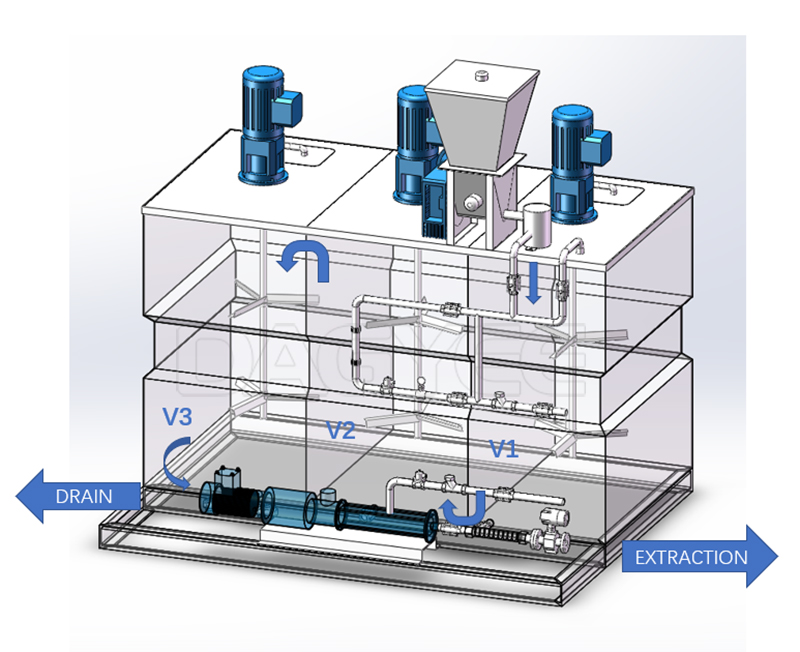

Polymer dissolving device

Polymer dissolving device is composed of pre-soaking device, tank, and 3 sets of mixers. The pre-soaking device is to infiltrate and mix the polymer powder in advance. The 3 tanks are precast mixing tank, homogeneous slaking tank and solution storage tank, in which there is a mixer correspond to guarantee the homogeneity.

Water supply device

Water supply device is composed of pipeline, manual ball valve, filter, pressure gauge, solenoid valve, stop valve, and the rotor flow meter, etc.

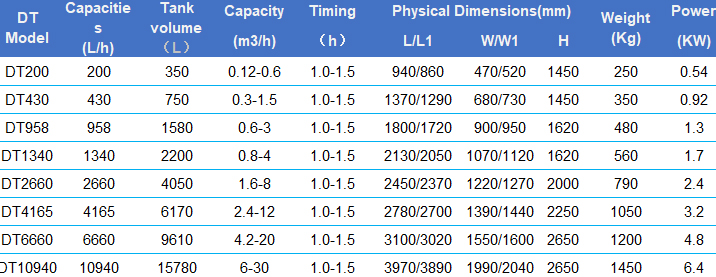

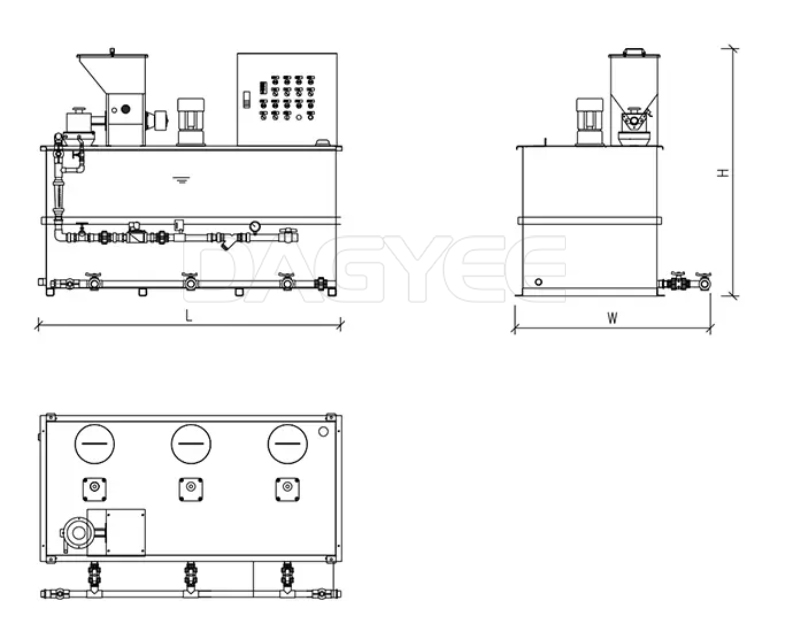

PAM Polymer Preparation Unit Model

PAM Polymer Preparation Advantage

The effectiveness of DAF units lies in their ability to handle a variety of wastewater streams, making them indispensable across multiple industries. Whether in industrial settings dealing with complex contaminants or municipal systems facing large volumes of urban runoff, DAF units prove their versatility and efficiency. They are particularly renowned in industries such as food and beverage production, where they handle organic matter and fats with ease, and in the oil and gas sector, where the separation of hydrocarbons is critical. Furthermore, the technology is adaptable, with configurations allowing for the introduction of various chemicals to optimize performance based on specific treatment needs.

Beyond their application flexibility, DAF units offer significant advantages including high removal efficiency, low operating costs, flexibility in operation, and a compact footprint. This makes them a viable solution even for facilities with space constraints or those looking to upgrade their existing wastewater treatment infrastructure. However, it’s important to note that the complexity of these systems often necessitates skilled operators to manage and maintain optimal performance. Proper pre-treatment steps such as Coarse Screening, homogenization, sand removal, and coagulation-flocculation are also essential to ensure maximum efficiency and longevity of the DAF units.

PAM Polymer Preparation Application

Wastewater Treatment

Desalination

Process Water Production

Drinking Water Intake

Offshore Produced Water

Onshore Produced Water

Pulp and Paper Plan

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China