PAM polymer preparation unit Description

Dissolved-air flotation processes are designed to enhance the efficiency of solid-liquid separation in wastewater treatment. The core principle revolves around saturating the influent stream with air under high pressure, allowing a significant amount of air to dissolve in the water. Once this water is released into the flotation chamber, the pressure drops, causing the dissolved air to form microbubbles. These microbubbles exhibit a unique ability to attach to suspended particles, leading to effective removal of contaminants.

DAF systems are widely recognized for their ability to mitigate issues related to sedimentation and gravity thickening methods. Unlike traditional methods, which often rely heavily on the weight of solids to facilitate separation, dissolved-air flotation relies on the buoyancy provided by air bubbles. This shift in mechanism results in enhanced removal efficiencies, especially in low-density or finely suspended particles. Consequently, DAF has emerged as a preferred choice across various industries, particularly where space is limited or where rapid treatment times are necessary.

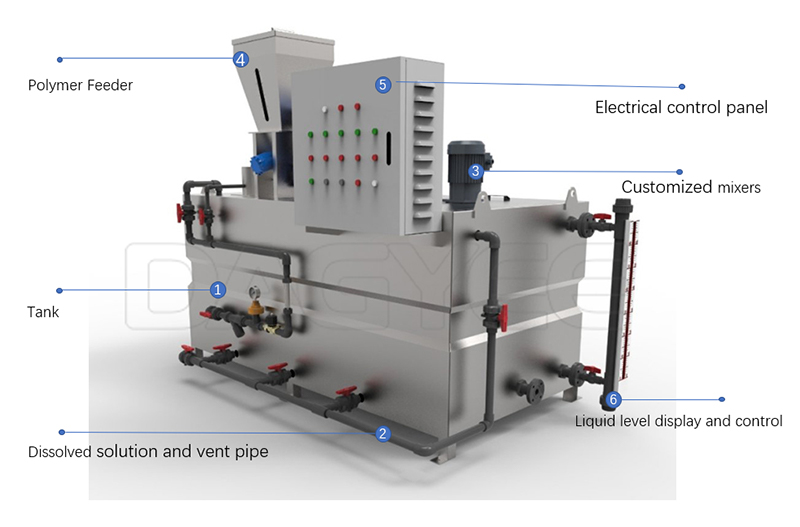

Polymer dosing device

Polymer dosing device is composed of hopper, push screw, electric heater and etc. The effective volume of the hopper can meet the dosage for a long time which is equipped with sight glasses for observing material level monitored by the dry powder level meter. The push screw driven by the high-precision reducer can satisfy the dosage. The electric heater can be installed in the discharge pipe of push screw, and it can prevent the powder from caking.

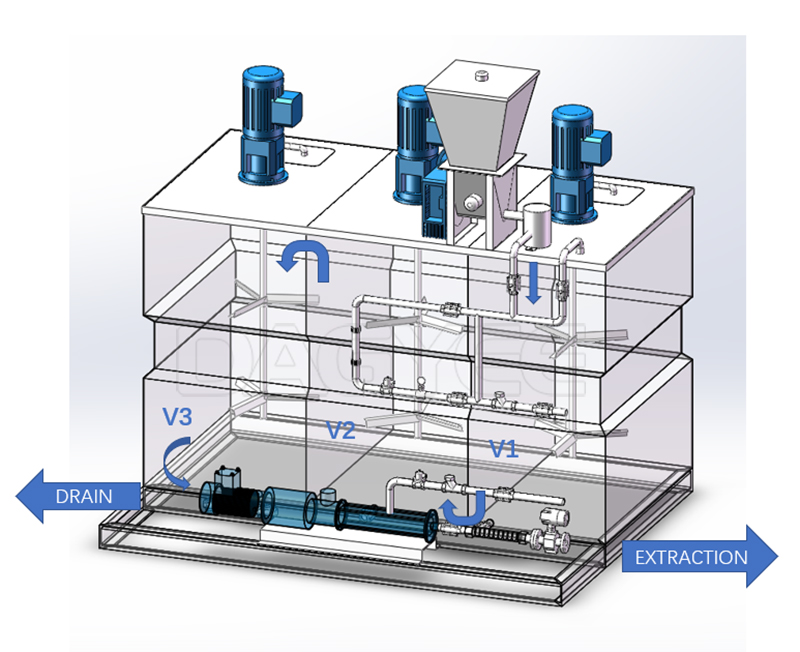

Polymer dissolving device

Polymer dissolving device is composed of pre-soaking device, tank, and 3 sets of mixers. The pre-soaking device is to infiltrate and mix the polymer powder in advance. The 3 tanks are precast mixing tank, homogeneous slaking tank and solution storage tank, in which there is a mixer correspond to guarantee the homogeneity.

Water supply device

Water supply device is composed of pipeline, manual ball valve, filter, pressure gauge, solenoid valve, stop valve, and the rotor flow meter, etc.

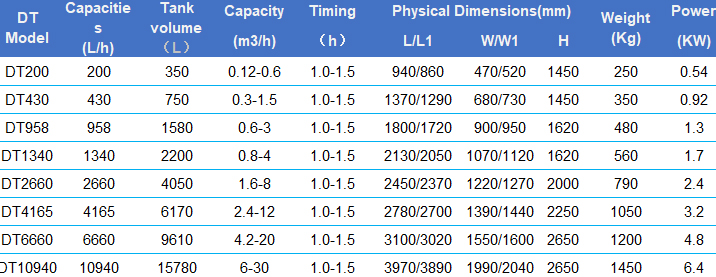

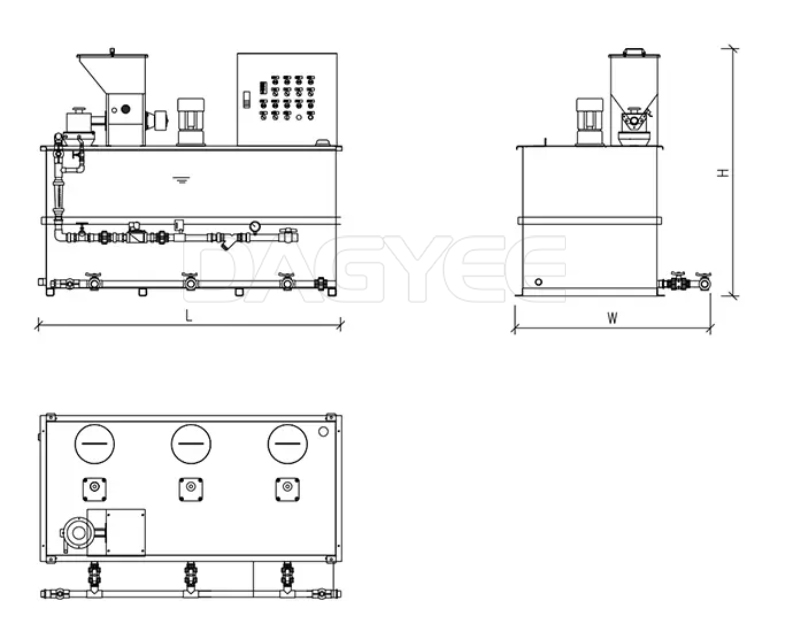

PAM Polymer Preparation Unit Model

PAM Polymer Preparation Function

The overall effectiveness of a DAF unit can often be linked to the efficiency of each individual component. During the pre-treatment phase, the wastewater is first mixed with a chemical coagulant. This crucial step facilitates the aggregation of fine particles into larger flocs, making them easier to separate from the water.

Once the influent feed is adequately treated, it moves into the air dissolving vessel. Here, compressed air is introduced under high pressure to dissolve into the water until the saturation point is reached. This saturation process is essential, as it ensures that when the pressure is released, a myriad of tiny microbubbles form uniformly throughout the flotation tank.

These microbubbles play a pivotal role in the separation process. When the air-water mixture is released into the flotation tank, the dissolved air comes out of solution, forming bubbles that attach to the flocculated particles, giving them buoyancy. The air bubble-particle aggregates rise to the surface, creating a floating sludge layer.

Simultaneously, heavier particles that cannot attach to the bubbles sink to the bottom as settleable solids. This dual mechanism effectively separates the floatable and settleable solids from the water.

The flotation tank’s skimmer system sweeps across the surface to remove the floating sludge, directing it towards a collection trough. This collected sludge can then be processed or disposed of according to regulatory requirements. At the same time, the clarified water, now free of suspended particles, is extracted from the bottom or sides of the tank and moved on to subsequent treatment stages or discharged if it meets quality standards.

The precise operation parameters, such as air-to-solids ratio and hydraulic loading rate, can significantly influence DAF performance. Regular monitoring and adjustments ensure optimal functioning, making the DAF unit a versatile and reliable choice for various wastewater treatment scenarios.

PAM Polymer Preparation Application

Fats, Oils, & Grease (FOB) Removal

Wastewater Pre-treatment

Wastewater Tertiary Treatment (P removal)

Sludge Thickening

Anaerobic/Aerobic Post Treatment and Sludge Separation

Filter Back Wash treatment

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China