Lamella Separator Description

Gravity Settler is a pre-assembled, modular, high rate inclined plate settler that uses a counter-current flow principle for effective solids removal. The inclined plate concept provides an effective settling area that is equal to the field of each plate as projected onto a horizontal surface. Using the standard 2″ plate spacing and 55°-60°, up to 10 ft² of projected area become available for each square foot of land area.

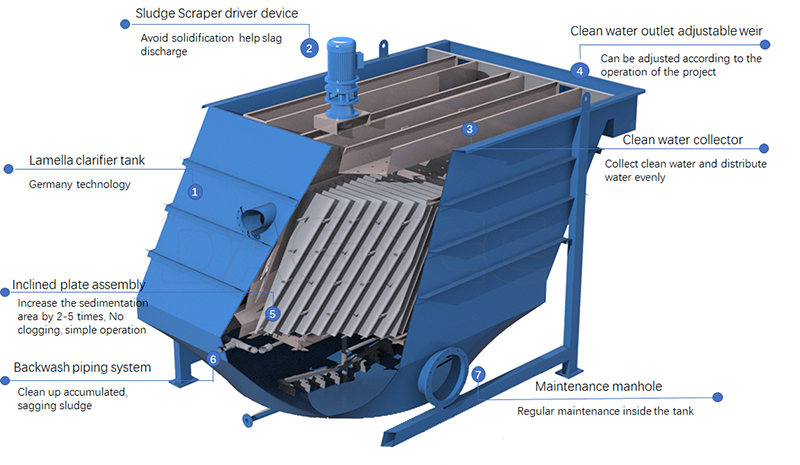

Structures

Lamella Separator Model

DLC-I Gravity Lamella ,V shape mud bucket, simple structure, no energy consumption.

DLC-II Lamella with scraper,Increase the mechanical transmission mechanism, the mud discharge is better and smoother, and it matches the unit with large processing capacity.

DLC-III Super hydraulic Lamella,Reduced footprint, efficient sedimentation, detachable transportation.

DLC

Model

Capacities

(m3/h)

Piping Connections()

Physical Dimensions(m)

Inlet(a)

Effluent(b)

Sludge(c)

Backwash(d)

L

W

H

DLC-

5

80

80

50

50

2.55

1.6

2.9

DLC-

10

100

100

50

50

3.35

1.82

3

DLC-

15

100

100

50

50

3.35

2.02

3

DLC-

20

100

100

50

50

3.35

2.02

3

DLC-

30

150

150

50

50

4.2

2.22

3

DLC-

40

150

150

50

50

4

2.8

3

DLC-

50

200

200

50

50

4.65

2.82

3

DLC-

60

200

200

50

50

4.7

3

3

DLC-

70

250

200

50

50

6.4

2.6

3

DLC-

80

250

200

50

50

6.8

2.82

3

DLC-

100

250

250

50

50

7.05

3.02

3

Lamella Separator Advantages

Lamella clarifiers present several benefits in wastewater treatment processes. They are designed to maximize settling efficiency while minimizing the footprint required.

Compact Design: Lamella clarifiers utilize inclined plates, which provide a large effective settling area within a compact unit. This design vastly increases the surface area for sedimentation compared to conventional clarifiers.

High Efficiency: Due to the increased surface area from the inclined plate design, settling is more efficient. Suspended particles are effectively removed, making it suitable even for high-flow applications.

Cost-effectiveness: The efficiency of lamella clarifiers can lead to reduced operational costs. They offer better process performance in a smaller space, leading to potential savings in construction and land costs.

Flexibility: These clarifiers can be used in various settings, including both traditional and parallel treatment trains, in new or existing wastewater facilities.

Reduced Sludge Volume: An efficient solid-liquid separation results in less sludge volume, which subsequently reduces the cost associated with sludge handling and disposal.

Low Maintenance: The simplicity of the lamella design often results in lower maintenance needs. Fewer moving parts equate to less wear and tear, as well as lower operational complexity.

By providing advantages such as a compact footprint, efficient processing, and low maintenance, lamella clarifiers have become a favorable option for many wastewater treatment facilities aiming to improve their solid-liquid separation stages.

Lamella Separator Applications

Water following physical-chemical treatment.

Tailings in mining and metallurgical beneficiation.

Solutions from gold leaching processes.

Wet scrubbing effluents.

Effluent treatment in pulp and paper mills.

Filter backwash.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China