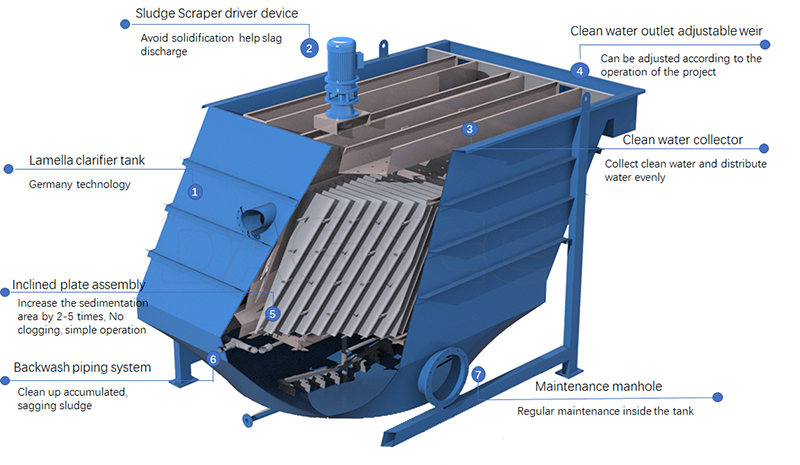

Lamella Separator Description

Lamella clarifiers are an integral component of modern wastewater treatment processes, enhancing sedimentation efficiency through an innovative design that optimizes the separation of solid particles from the liquid.

Functions

Lamella Separator Model

DLC-I Gravity Lamella ,V shape mud bucket, simple structure, no energy consumption.

DLC-II Lamella with scraper,Increase the mechanical transmission mechanism, the mud discharge is better and smoother, and it matches the unit with large processing capacity.

DLC-III Super hydraulic Lamella,Reduced footprint, efficient sedimentation, detachable transportation.

DLC

Model

Capacities

(m3/h)

Piping Connections()

Physical Dimensions(m)

Inlet(a)

Effluent(b)

Sludge(c)

Backwash(d)

L

W

H

DLC-

5

80

80

50

50

2.55

1.6

2.9

DLC-

10

100

100

50

50

3.35

1.82

3

DLC-

15

100

100

50

50

3.35

2.02

3

DLC-

20

100

100

50

50

3.35

2.02

3

DLC-

30

150

150

50

50

4.2

2.22

3

DLC-

40

150

150

50

50

4

2.8

3

DLC-

50

200

200

50

50

4.65

2.82

3

DLC-

60

200

200

50

50

4.7

3

3

DLC-

70

250

200

50

50

6.4

2.6

3

DLC-

80

250

200

50

50

6.8

2.82

3

DLC-

100

250

250

50

50

7.05

3.02

3

Lamella Separator Characteristics

By utilizing inclined plates, lamella clarifiers increase the effective settling area for particle removal. This design attribute enables a quicker and more effective separation process compared to traditional horizontal settlers. Due to this, they can achieve:

1. Higher flow rates

2. Improved effluent quality

3. Greater operational flexibility

Moreover, their modular nature allows for ease of installation and expansion to accommodate varying treatment capacities. The presence of lamella technology in wastewater treatment underscores the continued innovation towards more efficient and space-saving solutions in environmental management.

Lamella Separator Applications

Gravel and sand industry

Recycling industry

Glass / Ceramics / natural stone

Chemical industry

Energy industry / cooling water

Tunneling / construction sites

Waste / Landfill / street-cleaning

Heavy metal precipitation

Municipal water treatment Systems

Wet scrubber and slaking effluents in the power industry

Thickening processes in the chemical, mining and mineral industries

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China