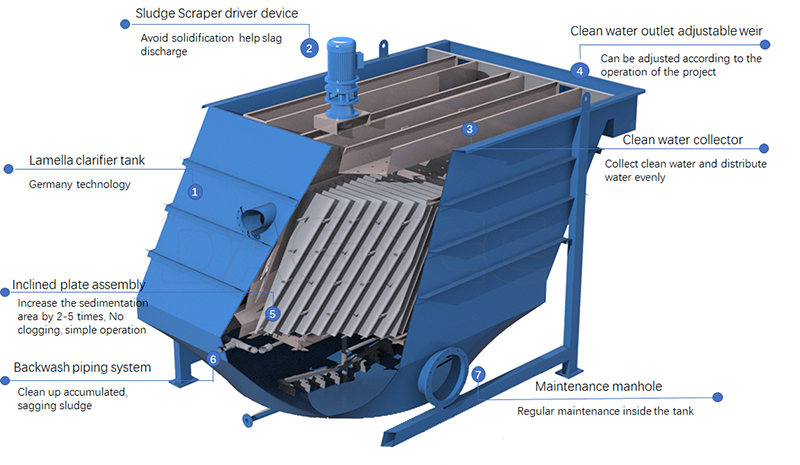

Lamella Separator Description

The implementation of lamella clarifiers in wastewater treatment is widely recognized due to their numerous advantages, such as their ability to handle high flow rates and their versatility across various industries. They are an essential element in the treatment process, appearing in sectors like municipal sewage treatment, industrial effluent processing, and water recycling. Proper installation and maintenance of lamella clarifiers are crucial for their optimal performance and compliance with environmental regulations. Recent technological advancements have further improved the efficacy of these systems, making them more sustainable and cost-effective solutions for wastewater management.

Functions

Lamella Separator Model

DLC-I Gravity Lamella ,V shape mud bucket, simple structure, no energy consumption.

DLC-II Lamella with scraper,Increase the mechanical transmission mechanism, the mud discharge is better and smoother, and it matches the unit with large processing capacity.

DLC-III Super hydraulic Lamella,Reduced footprint, efficient sedimentation, detachable transportation.

DLC

Model

Capacities

(m3/h)

Piping Connections()

Physical Dimensions(m)

Inlet(a)

Effluent(b)

Sludge(c)

Backwash(d)

L

W

H

DLC-

5

80

80

50

50

2.55

1.6

2.9

DLC-

10

100

100

50

50

3.35

1.82

3

DLC-

15

100

100

50

50

3.35

2.02

3

DLC-

20

100

100

50

50

3.35

2.02

3

DLC-

30

150

150

50

50

4.2

2.22

3

DLC-

40

150

150

50

50

4

2.8

3

DLC-

50

200

200

50

50

4.65

2.82

3

DLC-

60

200

200

50

50

4.7

3

3

DLC-

70

250

200

50

50

6.4

2.6

3

DLC-

80

250

200

50

50

6.8

2.82

3

DLC-

100

250

250

50

50

7.05

3.02

3

Lamella Separator Advantages

1. Lamella clarifiers utilize sedimentation to efficiently separate solids from wastewater.

2. Their compact, inclined plate design allows for effective treatment within a small space.

3. They are pivotal in meeting industry standards and environmental regulations for wastewater disposal.

Lamella clarifiers are characterized by their stacked plate design and sludge collection mechanisms. The compact arrangement allows for a high rate of clarification in a small space. During operation, a steady flow of wastewater enters the clarifier and distributes evenly across the plates, maximizing the use of available area for particle settling.

Ensuring even flow distribution is vital for the optimal performance of a Lamella clarifier. The influent must be evenly spread across the entire surface area to prevent channeling or short-circuiting, which can decrease removal efficiency. The design typically includes baffles or distribution channels to promote uniform flow across each plate, allowing for consistent sedimentation across the clarifier.

Lamella Separator Applications

Water following physical-chemical treatment.

Tailings in mining and metallurgical beneficiation.

Solutions from gold leaching processes.

Wet scrubbing effluents.

Effluent treatment in pulp and paper mills.

Filter backwash.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China