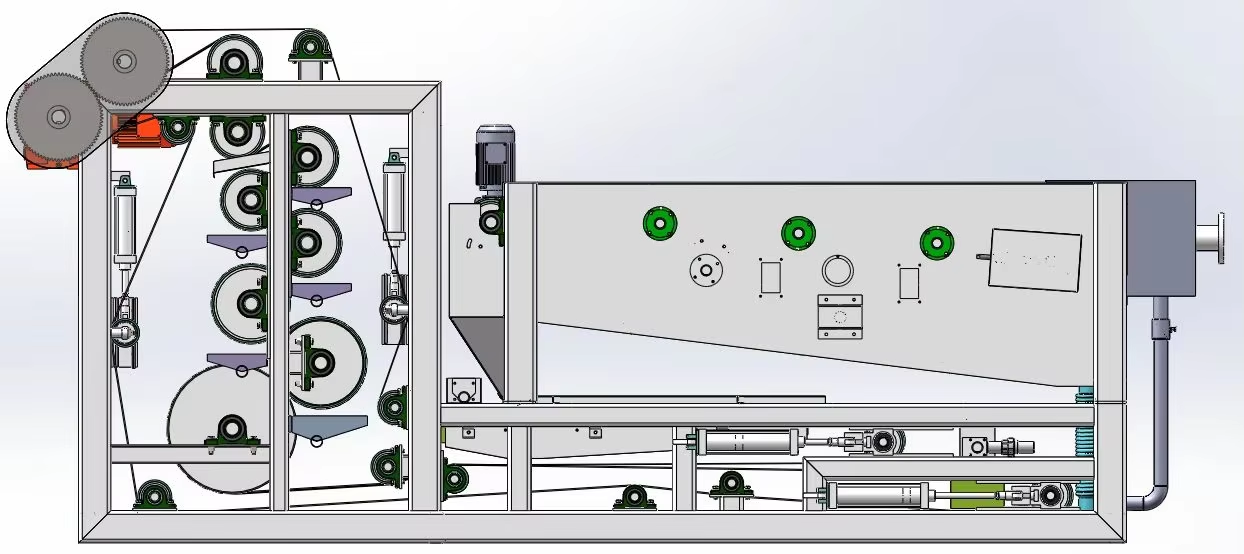

A Belt Filter Press is a sludge dewatering device that applies mechanical pressure to a chemically conditioned slurry, which is sandwiched between two tensioned belts, by passing those belts through a serpentine of decreasing diameter rolls. The machine can actually be divided into three zones: the gravity zone, where free draining water is drained by gravity through a porous belt; the wedge zone, where the solids are prepared for pressure application; and the pressure zone, where medium, then high pressure is applied to the conditioned solids.

Many belt press designs and filtration processes are available, but all incorporate the following basic features: polymer conditioning zone, gravity drainage zones, low pressure squeezing zone, and high pressure squeezing zones. A belt filter dewaters biosolids or industrial sludges by applying pressure to squeeze out the water or liquid phase. Belt Filter Presses are available in a three-belt, a two-belt, and an extended gravity two-belt design. Advanced designs provide a large filtration area, additional rollers, and variable belt speeds that can increase cake solids.

Belt filter technical sheet

| Sludge Kinds | Input Concentration % | Capacity m³/h | DS Capacity kg/h | Moisture of Cake % | PAM Consumption %(DP/DS) |

| Unconcentrated Aerobic Sludge | 0.5~1.5 | 15~30 | 150~300 | ~80 (+2) | 2~5 |

| Concentrated Aerobic Sludge | 2~4 | 6~12 | 200~300 | ~80 (+2) | 2~5 |

| Digested Sludge | 3~6 | 7~15 | 300~400 | <80 | 2~5 |

| Unconcentrated Primary Sludge | 0.8~2.0 | 18~35 | 300~400 | <80 | 2~5 |

| Concentrated Primary Sludge | 3~5 | 6~12 | 300~400 | <80 | 2~5 |

| Paper-making Activated Sludge | 0.5~2.5 | 15~35 | 200~400 | <78 | 3~7 |

| Printing and Dyeing Mixed Sludge | 1~3 | 10~25 | 180~350 | 75~78 | 3~10 |

| Model | Belt Width | Sludge Concentration | Outlet Concentration | Capacity | Power |

| DNT-1000 | 1000mm | 2-4% | 15-25% | 6-12 | 1.49kW |

| DNT-1500 | 1500mm | 2-4% | 15-25% | 12-15 | 2.05kW |

| DNT-2000 | 2000mm | 2-4% | 15-25% | 15-25 | 2.6kW |

| DNT-2500 | 2500mm | 2-4% | 15-25% | 35-50 |

4.1kW |

Belt filter press applications

Belt filter presses can be used to dewater most biosolids generated at municipal wastewater treatment plants and are a common type of mechanical dewatering equipment.

Using mechanical equipment to dewater solids may not be the most cost effective alternative for wastewater treatment plants operating at less than about 4 mgd.

The selection of dewatering equipment should be based on the results of a site specific biosolids management plan which identifies both processing and end use alternatives and estimates costs.

It may be less expensive to haul liquid to an application site or pay a processing facility to dewater and process or landfill the dewatered cake.

Smaller facilities should also evaluate non-mechanical dewatering methods, such as drying beds or reed beds.

Contact Us for a Consultation

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China