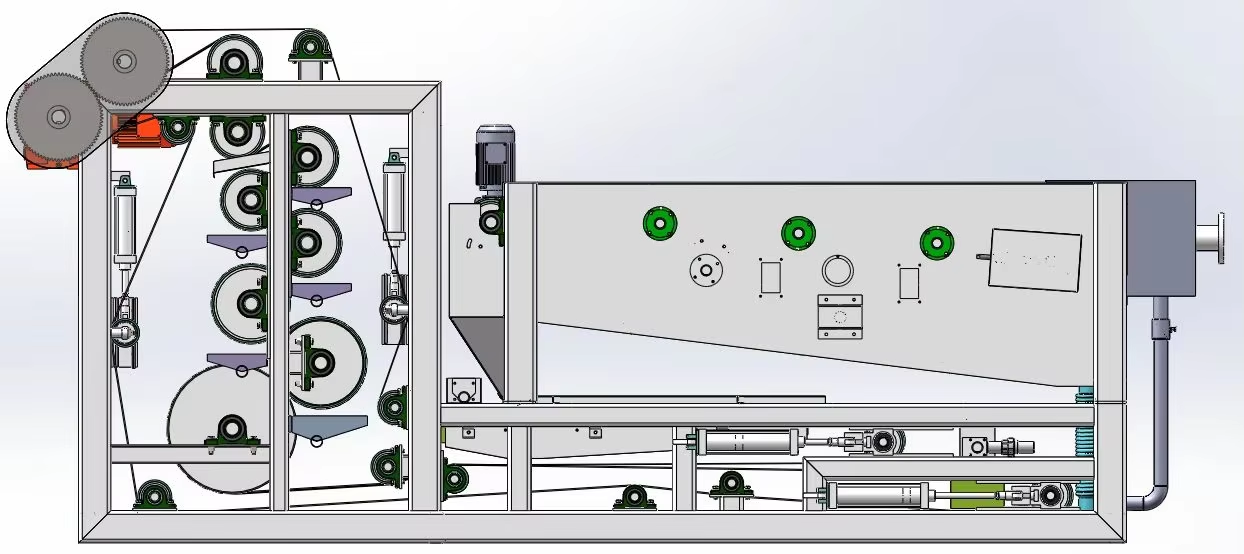

A Belt Filter Press is a sludge dewatering device that applies mechanical pressure to a chemically conditioned slurry, which is sandwiched between two tensioned belts, by passing those belts through a serpentine of decreasing diameter rolls. The machine can actually be divided into three zones: the gravity zone, where free draining water is drained by gravity through a porous belt; the wedge zone, where the solids are prepared for pressure application; and the pressure zone, where medium, then high pressure is applied to the conditioned solids.

Sludge mixed with polymer is introduced.

The mixture gradually rises where the polymer and sludge separate.

Mixture is evenly and gently spread across belt width by the leveling baffle.

The mixture “pools” and then is conveyed upward during which time free water drains through the belt. The thickening process can be aided by the use of ploughs.

Thickened sludge is trapped between the two screens and gradually subjected to increasing pressure.

Shearing and compression occurs as the sludge travels around rolls of decreasing diameter due to the forces exerted by the independent pneumatic tensioning of both belts.

The dewatered sludge is discharged away from the belts which is then doctored and washed before returning to accept more sludge.

Belt filter technical sheet

| Sludge Kinds | Input Concentration % | Capacity m3/h | DS Capacity kg/h | Moisture of Cake % | PAM comsuption %(DP/DS) |

| Unconcentrated Aerobic Sludge | 0.5~1.5 | 15~30 | 150~300 | ~80 (+2) | 2~5 |

| Concentrated Aerobic Sludge | 2~4 | 6~12 | 200~300 | ~80 (+2) | 2~5 |

| Digested Sludge | 3~6 | 7~15 | 300~400 | less than 80 | 2~5 |

| Unconcentrated Primary Sludge | 0.8~2.0 | 18~35 | 300~400 | less than 80 | 2~5 |

| Concentrated Primary Sludge | 3~5 | 6~12 | 300~400 | less than 80 | 2~5 |

| Paper-making Activated Sludge | 0.5~2.5 | 15~35 | 200~400 | less than 78 | 3~7 |

| Printing and Dyeing Mixed Sludge | 1~3 | 10~25 | 180~350 | 75~78 | 3~10 |

Model selection

| Model | Belt Width | Sludge Concentration | Outlet Concentration | Capacity | Power |

| DNT-1000 | 1000mm | 2-4% | 15-25% | 6-12 | 1.49kW |

| DNT-1500 | 1500mm | 2-4% | 15-25% | 12-15 | 2.05kW |

| DNT-2000 | 2000mm | 2-4% | 15-25% | 15-25 | 2.6kW |

| DNT-2500 | 2500mm | 2-4% | 15-25% | 35-50 |

4.1kW |

Belt filter press applications

Municipal and industrial sludge: Suitable for treating sludge from a variety of municipal and industrial sources.

Production By-Products: Efficiently treats by-products from the chemical, food and paper industries.

Mineral Industries

Mine Tailings Dewatering

Drilling and Tunneling

Sand, Clay and Mud

Abattoir, rendering plants and tanneries

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China