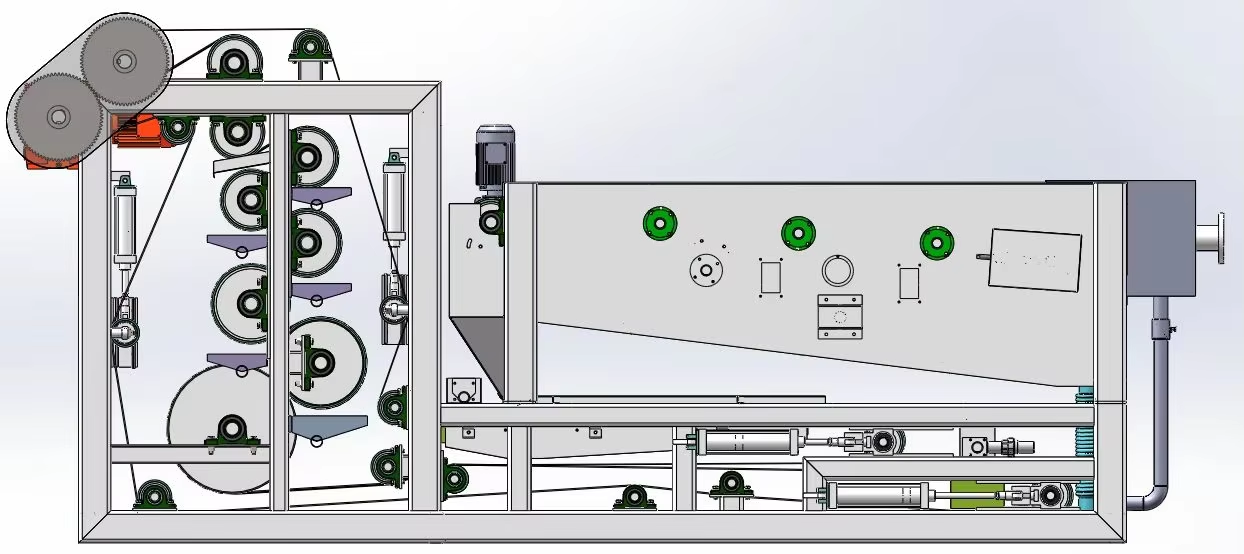

A belt filter press (BFP) provides sludge dewatering by pressing the sludge to force the water through a permeable medium. The process produces a cake (the dewatered product) having a dry solids (DS) content of 30% or more in the case of primary sludge. This is to be distinguished from the lower-energy gravity belt thickener process which achieves a maximum DS content of ~10%.

A BFP combines drainage and mechanical pressure sequentially to remove water. The equipment normally comprises 2−3 recirculating belts, with two belts combining at some point to compress the sludge and squeeze water from it.

Chemical Conditioning – Sludge is blended with polyelectrolyte or polymer feed in a conditioning tank. This allows solid particles to clump into agglomerate or flocs. The amount of polymer feed is a critical component to cakes with consistent thickness and moisture content.

Gravity Drainage – Sludge is fed onto the main filter belt, a monofilament woven fabric designed with high flow rates. Gravity dewaters the sludge as the belt approaches the next zone.

Low-Pressure Dewatering – The sludge travels into contact with the pressure belt, or top belt, gradually squeezing until they have sandwiched the forming cake.

High-Pressure Dewatering – Staggered rollers cause the two belts to shear as the main belt goes from direct contact with one roller to being pulled by the other belt’s contact with the next roller. At this stage, sludge has become dewatered cake.

Discharge – Scraper blades removed the cake from both belts, which separate and run through a spray wash before repeating the cycle.

Belt filter technical sheet

| Sludge Kinds | Input Concentration % | Capacity m³/h | DS Capacity kg/h | Moisture of Cake % | PAM Consumption %(DP/DS) |

| Unconcentrated Aerobic Sludge | 0.5~1.5 | 15~30 | 150~300 | ~80 (+2) | 2~5 |

| Concentrated Aerobic Sludge | 2~4 | 6~12 | 200~300 | ~80 (+2) | 2~5 |

| Digested Sludge | 3~6 | 7~15 | 300~400 | <80 | 2~5 |

| Unconcentrated Primary Sludge | 0.8~2.0 | 18~35 | 300~400 | <80 | 2~5 |

| Concentrated Primary Sludge | 3~5 | 6~12 | 300~400 | <80 | 2~5 |

| Paper-making Activated Sludge | 0.5~2.5 | 15~35 | 200~400 | <78 | 3~7 |

| Printing and Dyeing Mixed Sludge | 1~3 | 10~25 | 180~350 | 75~78 | 3~10 |

| Model | Belt Width | Sludge Concentration | Outlet Concentration | Capacity | Power |

| DNT-1000 | 1000mm | 2-4% | 15-25% | 6-12 | 1.49kW |

| DNT-1500 | 1500mm | 2-4% | 15-25% | 12-15 | 2.05kW |

| DNT-2000 | 2000mm | 2-4% | 15-25% | 15-25 | 2.6kW |

| DNT-2500 | 2500mm | 2-4% | 15-25% | 35-50 |

4.1kW |

Belt filter press applications

The belt filter is mainly used for dewatering of sludge and slurry and juice extraction from apples, pears and other fruits, as well as grapes for winemaking, etc. Belt filters are used both municipally and industrially in a range of areas including urban sewage and wastewater treatment, metallurgy and mining, steel plants, coal plants, breweries, dyeing, tanneries, as well as chemical and paper factories.

Contact Us for a Consultation

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China