Un filtro prensa de cinta es un sofisticado equipo diseñado para la deshidratación continua de lodos y fangos. Utiliza dos cintas móviles que comprimen el material entre ellas, separando eficazmente los sólidos de los líquidos. Este proceso es crucial en muchas aplicaciones industriales en las que se requiere una separación eficaz sólido-líquido.

El filtro prensa de cinta funciona según un principio sencillo pero eficaz. A medida que el lodo entra en el sistema, primero se somete a una zona de drenaje por gravedad donde se elimina el exceso de agua. A continuación, el material pasa por una zona de prensado a baja presión y, por último, por una zona de alta presión donde se produce la máxima deshidratación.

Una de las principales ventajas de un filtro prensa de banda es su funcionamiento continuo, que permite un alto rendimiento y un rendimiento constante. Las bandas, normalmente de materiales sintéticos, están diseñadas para soportar las presiones y los entornos químicos a los que se enfrentan, lo que garantiza su longevidad y fiabilidad.

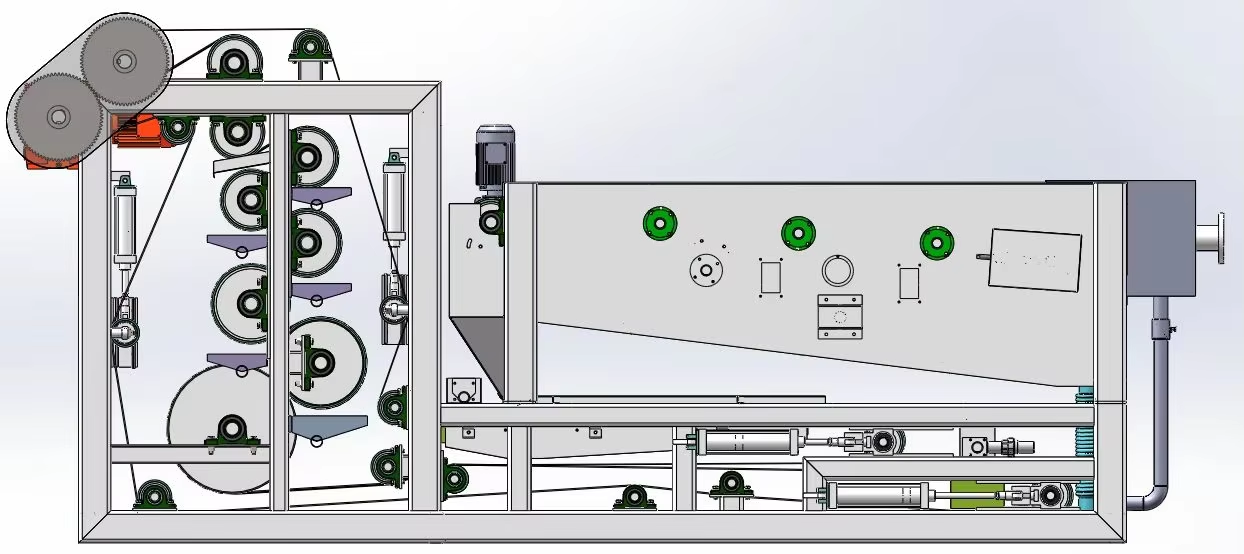

Feed Distributor: Unique, variable speed paddle wheel provides full belt-width distribution and uniform thickness.

Independent Gravity Zone: Allows for higher throughput capacity while achieving high cake solids.

Curved Wedge: Applies increasing pressure to cake with excellent cake retention to improve filtrate.

Vertical Pressure Rolls: Vertical arrangement allows for filtrate pans under each roll to keep filtrate from falling on adjacent rolls. This eliminates reabsorbtion of filtrate and improves discharge cake solids. Discharge height adequate for conveyor without raising press.

Tubular Frame Construction: Available as hot dipped galvanized, 304, 316 or duplex stainless steel. Tubular steel design for added frame rigidity, easy clean up and reduced O&M activity.

Machined bearing pads for precision frame and roller alignment.

Overall Layout: Gravity zone and controls located at operator level simplifies process optimization and eliminates costly platforms.

Belt filter technical sheet

| Sludge Kinds | Input Concentration % | Capacity m³/h | DS Capacity kg/h | Moisture of Cake % | PAM Consumption %(DP/DS) |

| Unconcentrated Aerobic Sludge | 0.5~1.5 | 15~30 | 150~300 | ~80 (+2) | 2~5 |

| Concentrated Aerobic Sludge | 2~4 | 6~12 | 200~300 | ~80 (+2) | 2~5 |

| Digested Sludge | 3~6 | 7~15 | 300~400 | <80 | 2~5 |

| Unconcentrated Primary Sludge | 0.8~2.0 | 18~35 | 300~400 | <80 | 2~5 |

| Concentrated Primary Sludge | 3~5 | 6~12 | 300~400 | <80 | 2~5 |

| Paper-making Activated Sludge | 0.5~2.5 | 15~35 | 200~400 | <78 | 3~7 |

| Printing and Dyeing Mixed Sludge | 1~3 | 10~25 | 180~350 | 75~78 | 3~10 |

| Model | Belt Width | Sludge Concentration | Outlet Concentration | Capacity | Power |

| DNT-1000 | 1000mm | 2-4% | 15-25% | 6-12 | 1.49kW |

| DNT-1500 | 1500mm | 2-4% | 15-25% | 12-15 | 2.05kW |

| DNT-2000 | 2000mm | 2-4% | 15-25% | 15-25 | 2.6kW |

| DNT-2500 | 2500mm | 2-4% | 15-25% | 35-50 |

4.1kW |

Belt filter press applications

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China