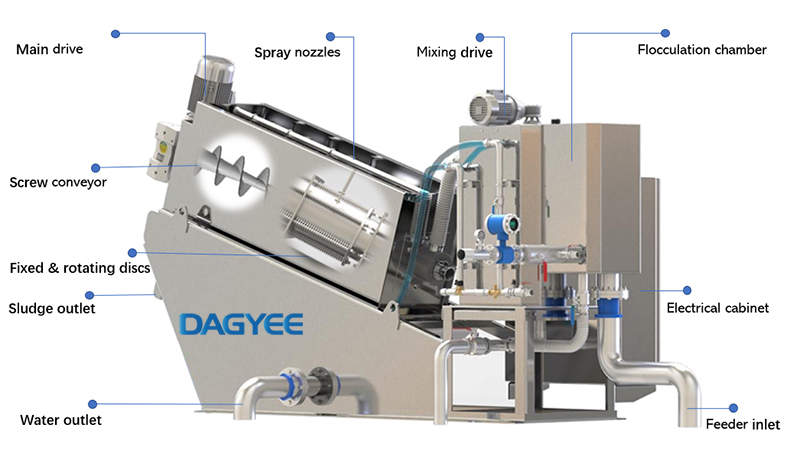

Sludge Dehydrator Description

The advanced range of sludge dewatering decanter centrifuges is ideal for making significant contributions to a sustainable environment. Its innovative design delivers peak performance at all times while reducing total power consumption by up to 40%. This improvement leads to substantial reductions in CO2 emissions during the sludge dewatering process.

Sludge Dehydrator Process

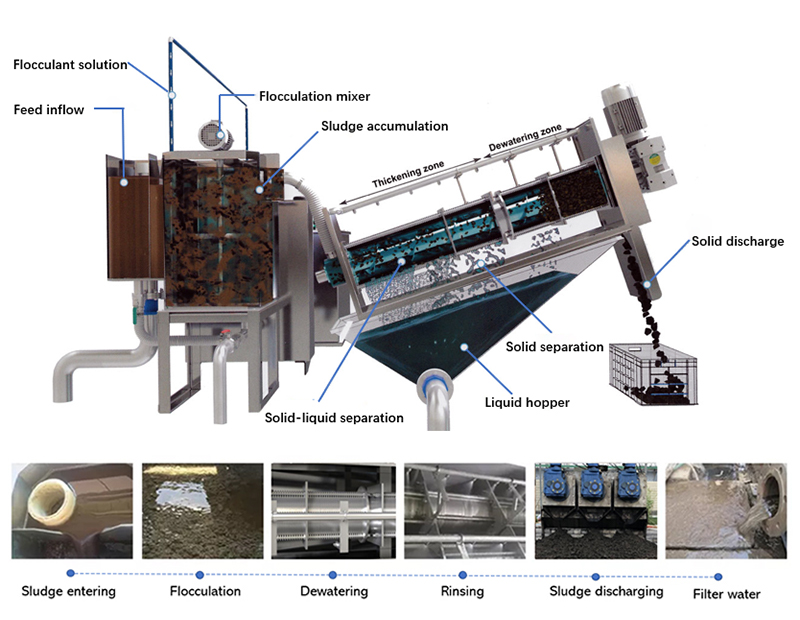

The initial section of dewatering drum is the thickening Zone, where the solid-liquid separating process takes place and where the filtrate will also be discharged. The pitch of the screw and the gap between the rings decrease at the end of dewatering drum, hence increasing its internal pressure, end Plate further increases the pressure, so as to discharge dry sludge cake.

Sludge is first flow into the Control Tank and then flows down into the Flocculation Tank, Where polymer coagulant is added.

From there, the flocculated sludge overflows into the dewatering drum where it is filtered and compressed. The entire operation sequence, including sludge feed control, polymer makeup, dosing and sludge cake discharge are controlled by the built-in timer and sensors of the PLC.

Sludge Dehydrator Model

Model

DL303

DS

capacity kg/h

90--150 kg/h

Sludge capacity m3/h(2-50g/L)

3-45

Spiral diameter mm

¢310*3

Discharge

Distance mm

495

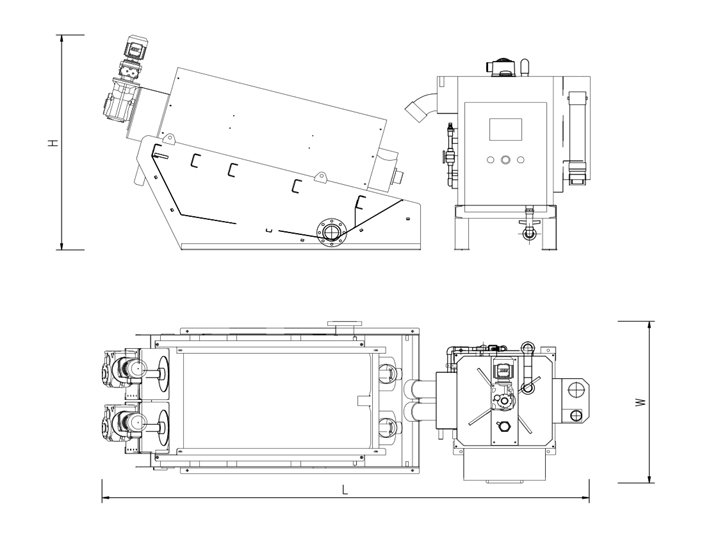

Size L*W*H

mm

3605*1690*1600

Net.Kg

1520

Run Kg

3080

Power

Kw

1.86

Washing Q L/h

120

Sludge Dehydrator Advantages

Sludge dewatering: Efficient performance data, Maximum operational safety, Optimized operating and disposal costs

The efficient and cost-effective DAGYEE series offers:

Sludge Dehydrator Application

Screw press dewatering machines uses a screw mechanism to squeeze and press the material to separate liquids from solids. These machines are suitable for processing animal waste, biogas slurry, paper pulp and other organic materials. The material is fed into the screw press, and as the screw turns, it moves the material along its length. With the decreasing pitch of the screw, the material is compressed. This compression helps to separate the liquid from the solid. The separated liquid flows out through the screen while the solid retains in the screen and continues to move along the screw. And they are finally discharged at end of the machine.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China