Dissolved-air flotation processes are designed to enhance the efficiency of solid-liquid separation in wastewater treatment. The core principle revolves around saturating the influent stream with air under high pressure, allowing a significant amount of air to dissolve in the water. Once this water is released into the flotation chamber, the pressure drops, causing the dissolved air to form microbubbles. These microbubbles exhibit a unique ability to attach to suspended particles, leading to effective removal of contaminants.

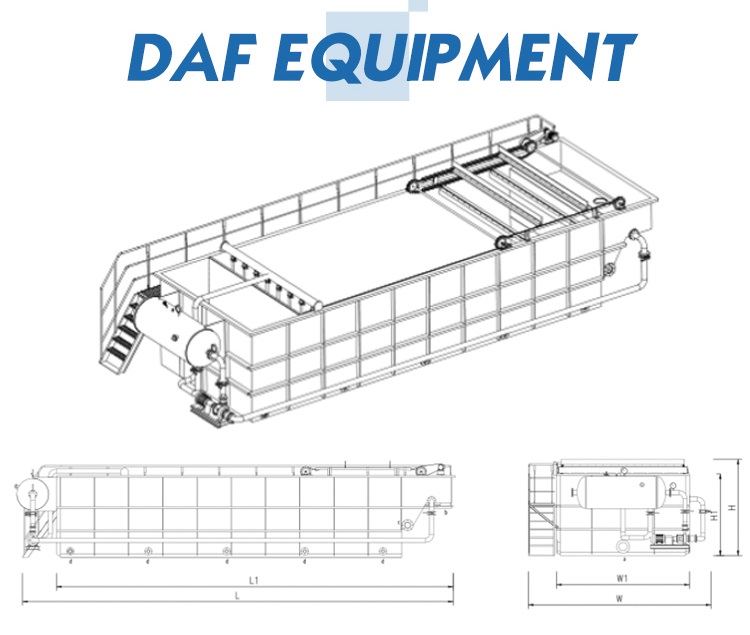

A typical dissolved-air flotation system comprises several integral components, each playing a crucial role in the overall functioning of the process. Key components include:

Flotation Tank: This is the primary vessel where the separation process occurs. It is designed to promote the coalescence of bubbles and suspended solids.

Air Saturation System: This consists of pumps and pressurization equipment that infuse the wastewater with dissolved air.

Sludge Removal Mechanism: Often designed as a skimmer, this component collects the thickened sludge that rises to the surface.

Effluent Collection System: A series of troughs or piping that ensures the treated water is channeled away from the system for further processing or discharge.

Control System: This consists of monitoring and control devices for regulating flow rates, pressure levels, and chemical dosing to ensure optimal operation.

Dissolved air flotation technical sheet

| DAF Model | Qm3/h | Piping Connections | Physical Dimensions(m) | Weight (Kg) | Operating Weight (Kg) |

|---|---|---|---|---|---|

| DAF-003 | 3 |

Inlet: DN50 Outlet: DN50 Sludge: DN100 Vent: DN100 |

L/L1: 3.7/2.8 W/W1: 2.4/1.16 H/H1: 2.2/1.7 |

1500 | 5000 |

| DAF-005 | 5 |

Inlet: DN80 Outlet: DN80 Sludge: DN100 Vent: DN80 |

L/L1: 4/3 W/W1: 2.4/1.16 H/H1: 2.2/1.7 |

1600 | 7000 |

| DAF-010 | 10 |

Inlet: DN100 Outlet: DN100 Sludge: DN100 Vent: DN100 |

L/L1: 4.65/3.8 W/W1: 2.7/1.36 H/H1: 2.4/1.9 |

2000 | 12000 |

| DAF-015 | 15 |

Inlet: DN125 Outlet: DN100 Sludge: DN150 Vent: DN100 |

L/L1: 5.6/4.5 W/W1: 2.9/1.66 H/H1: 2.5/2 |

2200 | 18000 |

| DAF-020 | 20 |

Inlet: DN150 Outlet: DN150 Sludge: DN150 Vent: DN100 |

L/L1: 5.9/4.8 W/W1: 3.2/1.96 H/H1: 2.5/2 |

3000 | 22000 |

| DAF-030 | 30 |

Inlet: DN150 Outlet: DN150 Sludge: DN150 Vent: DN100 |

L/L1: 6.8/5.5 W/W1: 3.2/2.16 H/H1: 2.7/2.2 |

3800 | 32000 |

| DAF-040 | 40 |

Inlet: DN200 Outlet: DN150 Sludge: DN150 Vent: DN100 |

L/L1: 8/6.7 W/W1: 3.6/2.6 H/H1: 2.7/2.2 |

5000 | 45000 |

| DAF-050 | 50 |

Inlet: DN200 Outlet: DN150 Sludge: DN150 Vent: DN100 |

L/L1: 8.4/7 W/W1: 3.6/2.6 H/H1: 2.7/2.2 |

5500 | 55000 |

| DAF-060 | 60 |

Inlet: DN250 Outlet: DN200 Sludge: DN150 Vent: DN100 |

L/L1: 9.9/8.4 W/W1: 3.8/2.8 H/H1: 2.9/2.4 |

6000 | 66000 |

| DAF-070 | 70 |

Inlet: DN250 Outlet: DN200 Sludge: DN150 Vent: DN100 |

L/L1: 10.4/9 W/W1: 3.8/2.8 H/H1: 2.9/2.4 |

6500 | 75000 |

| DAF-080 | 80 |

Inlet: DN250 Outlet: DN250 Sludge: DN150 Vent: DN100 |

L/L1: 10.8/9.4 W/W1: 4/3 H/H1: 2.9/2.4 |

7500 | 100000 |

| DAF-100 | 100 |

Inlet: DN300 Outlet: DN250 Sludge: DN150 Vent: DN100 |

L/L1: 12.1/10.6 W/W1: 4.2/3.2 H/H1: 2.9/2.4 |

9000 | 110000 |

| DAF-120 | 120 |

Inlet: DN300 Outlet: DN250 Sludge: DN150 Vent: DN100 |

L/L1: 12.5/11.4 W/W1: 4.4/3.4 H/H1: 2.9/2.4 |

10000 | 130000 |

Dissolved air flotation process flow

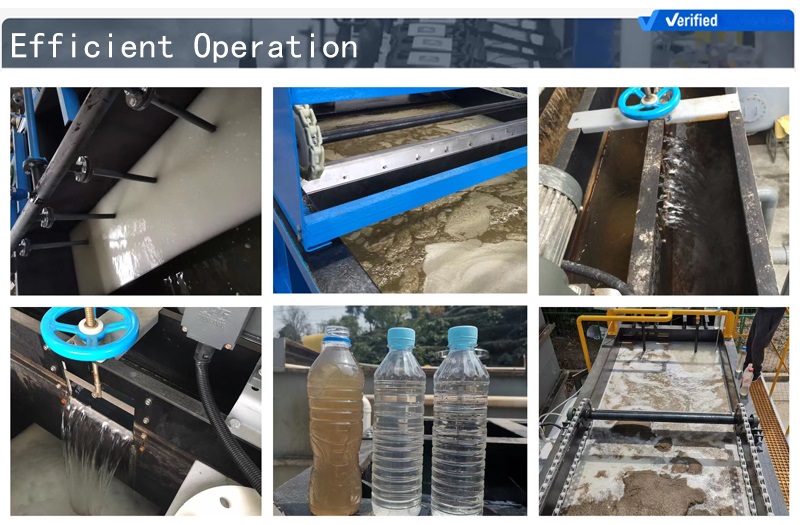

Improved Water Quality

Greater turbidity reduction

Discharge compliance

Greater treatment flexibility

Reduced chemical consumption

Operational Advantages

Small footprint

Zero backwash

Improved product quality

Simple and easy operation

Reduced downtime and operational cost

The environmental impact of DAF systems is generally positive, particularly in minimizing water pollution. By enabling the removal of over 90% of harmful components from industrial effluents, DAF systems contribute to cleaner water bodies and reduced environmental pollution. Moreover, reduced chemical usage and advancements in energy-efficient designs further enhance the sustainability of DAF technology.

Dissolved air flotation application

Wastewater Treatment

Desalination

Process Water Production

Drinking Water Intake

Offshore Produced Water

Onshore Produced Water

Pulp and Paper Plan

Contact Us for a Consultation

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China