Dissolved-air flotation (DAF) is a specialized air flotation technique used predominantly in the treatment of wastewater and industrial effluents. By utilizing the principle of buoyancy, DAF processes effectively separate solids from liquids, making the treatment process optimal for various applications. The method operates on the fundamental concept of introducing fine air bubbles into the wastewater, which attach to suspended solids. This attachment enables the solids to rise to the surface, resulting in the formation of a concentrated sludge layer, thus allowing for efficient water clarification.

The operational effectiveness of dissolved-air flotation processes can be largely attributed to the unique mechanism through which air bubbles facilitate the separation of solids from liquids. Initially, raw wastewater is introduced into a flotation tank, where it is pre-treated to prepare it for flotation. This pre-treatment commonly involves the addition of coagulants and flocculants, which help agglomerate fine particles into larger flocs.

Next, a high-pressure pump draws water from the flotation tank and saturates it with air, producing dissolved air at a concentration greater than it can hold at atmospheric pressure. Upon reaching the flotation chamber, pressure is released, and the excess air comes out of the solution, forming tiny bubbles that adhere to the suspended and colloidal particles within the wastewater. These adhered particles become buoyant and rise to the water's surface, forming a sludge layer that can be skimmed off. This mechanical method increases the overall efficiency of contaminant removal, resulting in treated water of higher clarity.

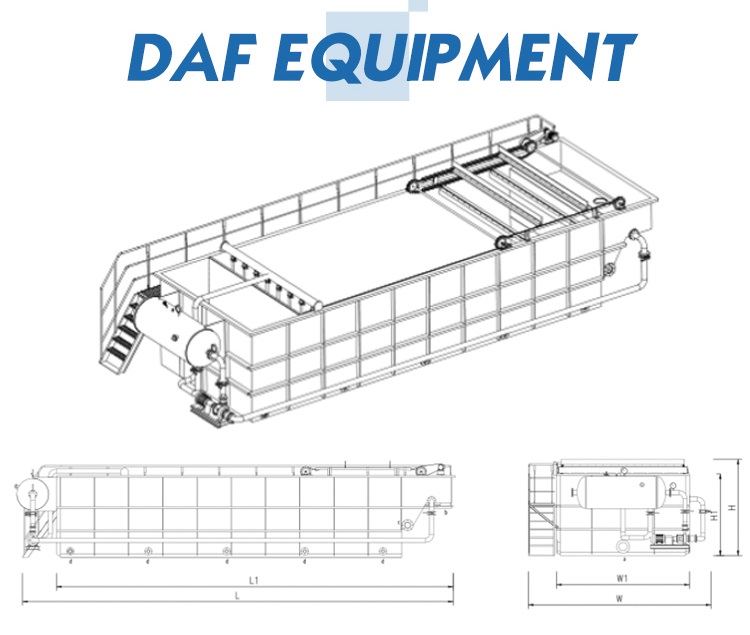

Dissolved air flotation technical sheet

| DAF Model | Qm3/h | Piping Connections | Physical Dimensions(m) | Weight (Kg) | Operating Weight (Kg) |

|---|---|---|---|---|---|

| DAF-003 | 3 |

Inlet: DN50 Outlet: DN50 Sludge: DN100 Vent: DN100 |

L/L1: 3.7/2.8 W/W1: 2.4/1.16 H/H1: 2.2/1.7 |

1500 | 5000 |

| DAF-005 | 5 |

Inlet: DN80 Outlet: DN80 Sludge: DN100 Vent: DN80 |

L/L1: 4/3 W/W1: 2.4/1.16 H/H1: 2.2/1.7 |

1600 | 7000 |

| DAF-010 | 10 |

Inlet: DN100 Outlet: DN100 Sludge: DN100 Vent: DN100 |

L/L1: 4.65/3.8 W/W1: 2.7/1.36 H/H1: 2.4/1.9 |

2000 | 12000 |

| DAF-015 | 15 |

Inlet: DN125 Outlet: DN100 Sludge: DN150 Vent: DN100 |

L/L1: 5.6/4.5 W/W1: 2.9/1.66 H/H1: 2.5/2 |

2200 | 18000 |

| DAF-020 | 20 |

Inlet: DN150 Outlet: DN150 Sludge: DN150 Vent: DN100 |

L/L1: 5.9/4.8 W/W1: 3.2/1.96 H/H1: 2.5/2 |

3000 | 22000 |

| DAF-030 | 30 |

Inlet: DN150 Outlet: DN150 Sludge: DN150 Vent: DN100 |

L/L1: 6.8/5.5 W/W1: 3.2/2.16 H/H1: 2.7/2.2 |

3800 | 32000 |

| DAF-040 | 40 |

Inlet: DN200 Outlet: DN150 Sludge: DN150 Vent: DN100 |

L/L1: 8/6.7 W/W1: 3.6/2.6 H/H1: 2.7/2.2 |

5000 | 45000 |

| DAF-050 | 50 |

Inlet: DN200 Outlet: DN150 Sludge: DN150 Vent: DN100 |

L/L1: 8.4/7 W/W1: 3.6/2.6 H/H1: 2.7/2.2 |

5500 | 55000 |

| DAF-060 | 60 |

Inlet: DN250 Outlet: DN200 Sludge: DN150 Vent: DN100 |

L/L1: 9.9/8.4 W/W1: 3.8/2.8 H/H1: 2.9/2.4 |

6000 | 66000 |

| DAF-070 | 70 |

Inlet: DN250 Outlet: DN200 Sludge: DN150 Vent: DN100 |

L/L1: 10.4/9 W/W1: 3.8/2.8 H/H1: 2.9/2.4 |

6500 | 75000 |

| DAF-080 | 80 |

Inlet: DN250 Outlet: DN250 Sludge: DN150 Vent: DN100 |

L/L1: 10.8/9.4 W/W1: 4/3 H/H1: 2.9/2.4 |

7500 | 100000 |

| DAF-100 | 100 |

Inlet: DN300 Outlet: DN250 Sludge: DN150 Vent: DN100 |

L/L1: 12.1/10.6 W/W1: 4.2/3.2 H/H1: 2.9/2.4 |

9000 | 110000 |

| DAF-120 | 120 |

Inlet: DN300 Outlet: DN250 Sludge: DN150 Vent: DN100 |

L/L1: 12.5/11.4 W/W1: 4.4/3.4 H/H1: 2.9/2.4 |

10000 | 130000 |

Dissolved air flotation process flow

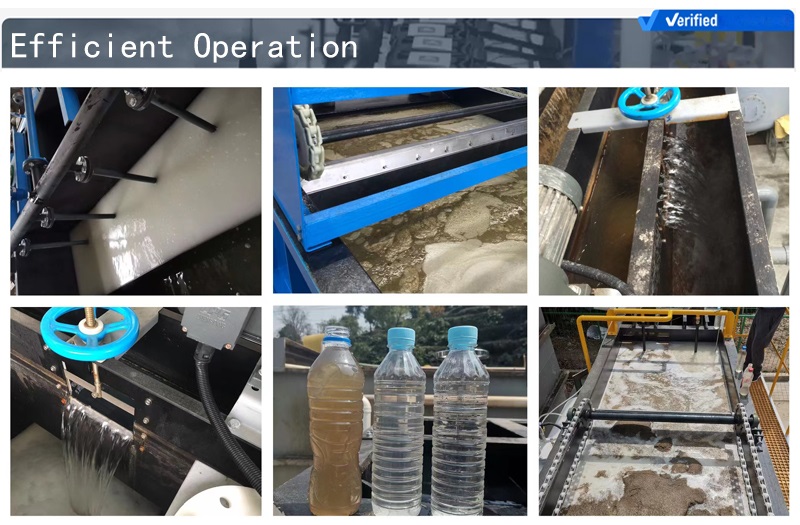

High Removal Efficency with Low Operational Costs.

DAF systems provide the flexibility to extract water throughout the process, extending retention time and improving effluent quality.

The technology provides high removal efficiency while maintaining low power and chemistry requirements.

Improved Separation and Sludge Removal.

Plate separators maximize the removal of solids.

The cross-flow design facilitates lower water velocities and better solid separation.

Systems accumulate thicker, denser sludge on the thickening beach and feature a cone bottom design for easy sludge removal.

Rugged Design, Long Life.

Heavy-duty, lightweight polypropylene (PP) construction.

Corrosion resistance.

High total dissolved solids (TDS) and saltwater tolerance.

Chemical treatment flexibility.

Wide pH range.

Up to 9,000 gallons per minute systems available.

The environmental impact of DAF systems is generally positive, particularly in minimizing water pollution. By enabling the removal of over 90% of harmful components from industrial effluents, DAF systems contribute to cleaner water bodies and reduced environmental pollution. Moreover, reduced chemical usage and advancements in energy-efficient designs further enhance the sustainability of DAF technology.

Dissolved air flotation application

Fats, Oils, & Grease (FOB) Removal

Wastewater Pre-treatment

Wastewater Tertiary Treatment (P removal)

Sludge Thickening

Anaerobic/Aerobic Post Treatment and Sludge Separation

Filter Back Wash treatment

Contact Us for a Consultation

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China