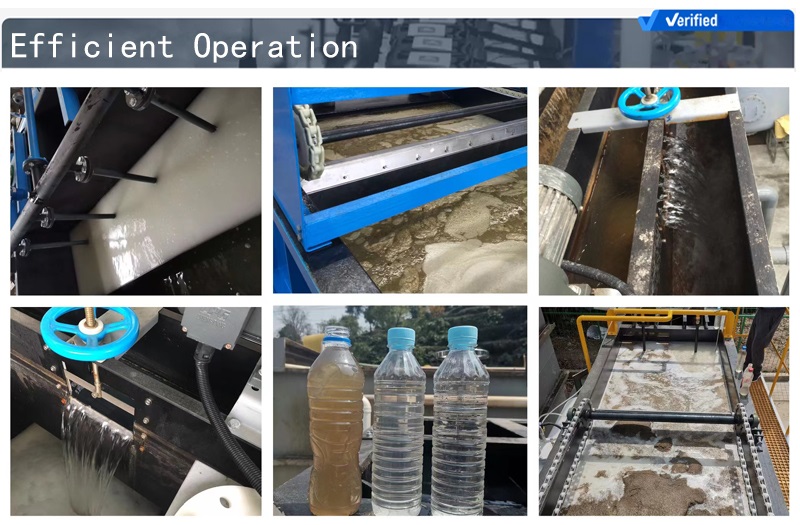

Dissolved Air Flotation (DAF) units play a pivotal role in modern wastewater treatment processes. These units are designed to remove suspended solids, oils, and other contaminants from wastewater by injecting air into the water under pressure. Once the pressure is released, tiny air bubbles interact with the suspended particles, causing them to float to the surface where they can be easily skimmed off. This process results in the production of clarified water which is then directed to the bottom of the flotation chamber and collected at an effluent control weir. By efficiently separating impurities, DAF units enhance the quality of treated water and ensure compliance with stringent environmental regulations.

The overall effectiveness of a DAF unit can often be linked to the efficiency of each individual component. During the pre-treatment phase, the wastewater is first mixed with a chemical coagulant. This crucial step facilitates the aggregation of fine particles into larger flocs, making them easier to separate from the water.

Once the influent feed is adequately treated, it moves into the air dissolving vessel. Here, compressed air is introduced under high pressure to dissolve into the water until the saturation point is reached. This saturation process is essential, as it ensures that when the pressure is released, a myriad of tiny microbubbles form uniformly throughout the flotation tank.

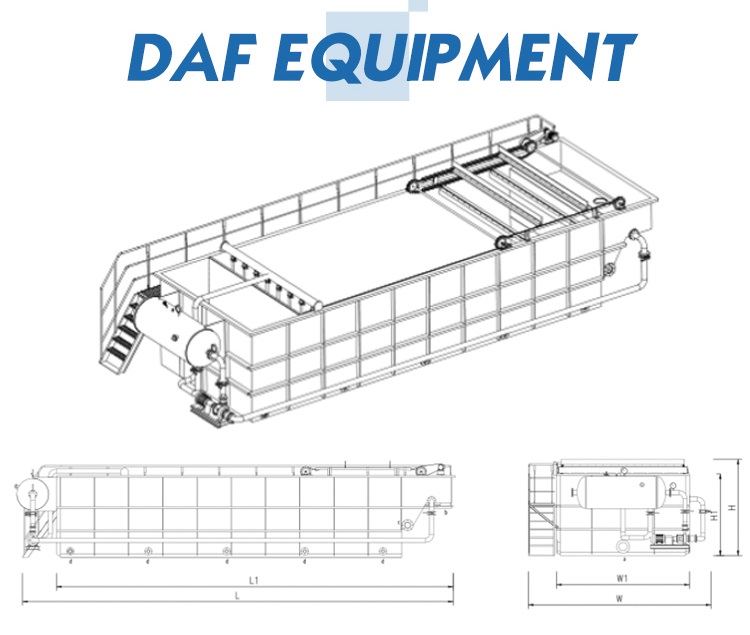

Dissolved air flotation technical sheet

| DAF Model | Qm3/h | Piping Connections | Physical Dimensions(m) | Weight (Kg) | Operating Weight (Kg) |

|---|---|---|---|---|---|

| DAF-003 | 3 |

Inlet: DN50 Outlet: DN50 Sludge: DN100 Vent: DN100 |

L/L1: 3.7/2.8 W/W1: 2.4/1.16 H/H1: 2.2/1.7 |

1500 | 5000 |

| DAF-005 | 5 |

Inlet: DN80 Outlet: DN80 Sludge: DN100 Vent: DN80 |

L/L1: 4/3 W/W1: 2.4/1.16 H/H1: 2.2/1.7 |

1600 | 7000 |

| DAF-010 | 10 |

Inlet: DN100 Outlet: DN100 Sludge: DN100 Vent: DN100 |

L/L1: 4.65/3.8 W/W1: 2.7/1.36 H/H1: 2.4/1.9 |

2000 | 12000 |

| DAF-015 | 15 |

Inlet: DN125 Outlet: DN100 Sludge: DN150 Vent: DN100 |

L/L1: 5.6/4.5 W/W1: 2.9/1.66 H/H1: 2.5/2 |

2200 | 18000 |

| DAF-020 | 20 |

Inlet: DN150 Outlet: DN150 Sludge: DN150 Vent: DN100 |

L/L1: 5.9/4.8 W/W1: 3.2/1.96 H/H1: 2.5/2 |

3000 | 22000 |

| DAF-030 | 30 |

Inlet: DN150 Outlet: DN150 Sludge: DN150 Vent: DN100 |

L/L1: 6.8/5.5 W/W1: 3.2/2.16 H/H1: 2.7/2.2 |

3800 | 32000 |

| DAF-040 | 40 |

Inlet: DN200 Outlet: DN150 Sludge: DN150 Vent: DN100 |

L/L1: 8/6.7 W/W1: 3.6/2.6 H/H1: 2.7/2.2 |

5000 | 45000 |

| DAF-050 | 50 |

Inlet: DN200 Outlet: DN150 Sludge: DN150 Vent: DN100 |

L/L1: 8.4/7 W/W1: 3.6/2.6 H/H1: 2.7/2.2 |

5500 | 55000 |

| DAF-060 | 60 |

Inlet: DN250 Outlet: DN200 Sludge: DN150 Vent: DN100 |

L/L1: 9.9/8.4 W/W1: 3.8/2.8 H/H1: 2.9/2.4 |

6000 | 66000 |

| DAF-070 | 70 |

Inlet: DN250 Outlet: DN200 Sludge: DN150 Vent: DN100 |

L/L1: 10.4/9 W/W1: 3.8/2.8 H/H1: 2.9/2.4 |

6500 | 75000 |

| DAF-080 | 80 |

Inlet: DN250 Outlet: DN250 Sludge: DN150 Vent: DN100 |

L/L1: 10.8/9.4 W/W1: 4/3 H/H1: 2.9/2.4 |

7500 | 100000 |

| DAF-100 | 100 |

Inlet: DN300 Outlet: DN250 Sludge: DN150 Vent: DN100 |

L/L1: 12.1/10.6 W/W1: 4.2/3.2 H/H1: 2.9/2.4 |

9000 | 110000 |

| DAF-120 | 120 |

Inlet: DN300 Outlet: DN250 Sludge: DN150 Vent: DN100 |

L/L1: 12.5/11.4 W/W1: 4.4/3.4 H/H1: 2.9/2.4 |

10000 | 130000 |

Dissolved air flotation process flow

There are several distinct advantages of using dissolved-air flotation processes compared to traditional wastewater treatment methods, such as sedimentation. One significant benefit is the ability to effectively treat low-density sludges, which often challenge gravity-based systems. DAF processes can successfully remove suspended solids, oils, and greases more efficiently by leveraging the air flotation technology.

Moreover, DAF systems often require less space than traditional sedimentation tanks due to their compact design and rapid treatment capability. This space-saving feature is particularly beneficial for industries operating in constrained environments or for those looking to modify existing waste treatment setups without extensive infrastructure changes. Additionally, the quick response of DAF systems allows for better control over fluctuating wastewater characteristics, making them ideal for environments with variable loads.

The environmental impact of DAF systems is generally positive, particularly in minimizing water pollution. By enabling the removal of over 90% of harmful components from industrial effluents, DAF systems contribute to cleaner water bodies and reduced environmental pollution. Moreover, reduced chemical usage and advancements in energy-efficient designs further enhance the sustainability of DAF technology.

Dissolved air flotation application

Dissolved air flotation design is instrumental in effective water treatment. This process is also widely used in several industries and sectors, including but not limited to:

Removing particles and treating industrial wastewater effluents at oil refineries.

Water treatment processing for petrochemical and chemical plants.

Water filtration for fuel gas conditioning plants and paper mills.

Industrial facilities requiring wastewater treatment for daily protocols or project-related processes.

Contact Us for a Consultation

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China