Static screen wastewater description

It’s a wedge wire twist panel that’s used in rigid strainer treatment plants’ for physical treatment systems.

There is no drive mechanism in static strainers. With the help of potential energy difference or flow energy of water, it does not need extra electrical energy consumption.

Static strainers are often used in industrial wastewater treatment plants; fine screening is possible in material, paper, slaughterhouse, food and plastic reusing wastewater

treatment plants.

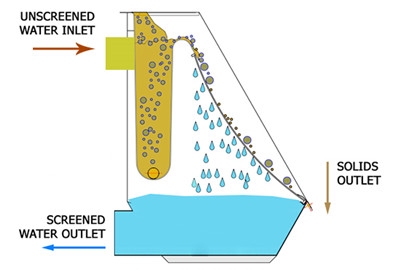

Static screen wastewater works

During dry weather conditions the flow to the treatment works will pass underneath the screens in the dry weather flow channel.

In a storm event the inflow rate to the chamber will exceed the outflow rate causing water levels to rise within the chamber and spill through the screens.

The Hydro-Static Screen is mounted over the dry weather flow channel so that the flow passes up and through the screen during a storm event.

Solids and floatables are trapped below the screen and returned to the sanitary continuation flow.

Screened effluent is discharged to a receiving waterway.

An emergency overflow weir is incorporated into the screen should the peak design flow be exceeded.

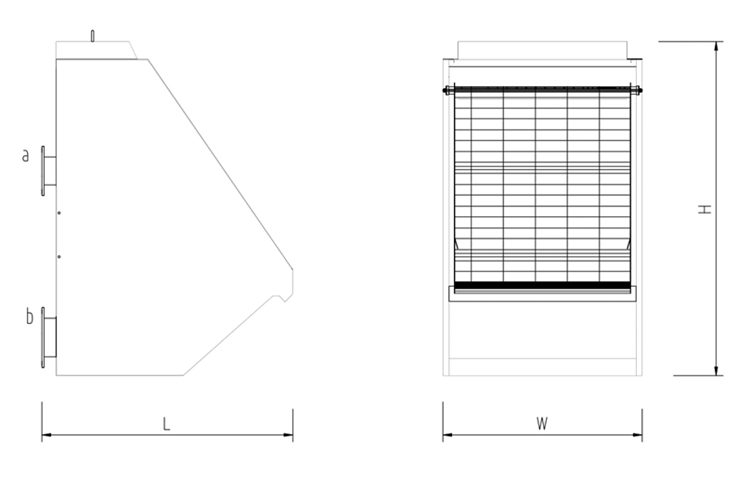

Static screen wastewater model

| HS Model |

Piping Connections Inlet(a) | Effluent(b) |

Physical Dimensions(m) L | W | H |

Weight (Kg) |

Capacities(m³/h) 0.5mm | 1mm | 1.5mm |

|---|---|---|---|---|

| HS-300 | 80 | 80 | 1.43 | 0.43 | 2 | 150 | 6 | 13 | 16 |

| HS-500 | 100 | 100 | 1.43 | 0.63 | 2 | 180 | 10 | 22 | 35 |

| HS-700 | 100 | 100 | 1.43 | 0.83 | 2 | 200 | 15 | 30 | 50 |

| HS-800 | 100 | 125 | 1.43 | 0.93 | 2 | 250 | 16 | 35 | 55 |

| HS-1000 | 150 | 150 | 1.43 | 1.13 | 2 | 280 | 20 | 45 | 70 |

| HS-1500 | 150 | 150 | 1.43 | 1.63 | 2 | 300 | 30 | 65 | 100 |

| HS-2000 | 200 | 200 | 1.43 | 2.13 | 2 | 400 | 40 | 75 | 120 |

Static screen wastewater advantage

1. Stainless steel construction: increases life span.

2. Bi-wave wedgewire: improves high capacity and keeps screen cleaner.

3. Drip lip: promotes drier solids.

4. Pivoting screen panel on larger units: provides easy access to rear of panel.

5. No moving parts: create a simple operation and reduce costs.

6. Optional covers and doors: reduce odors and provide customization options .

7. 5 models: provide flexible design offerings.

Static screen wastewater feature

1. Cleaning of the static screen filter can be accomplished by reverse scanning/cleaning mechanism which is specially designed to clean the front and back of the screen or with high pressure wash.

2. Cleaning of the screen can be accomplished automatically using differential water level sensors or time.

3. The ultra-low power consumption of the unit means operation and cleaning can be powered using solar panels.

4. Through the use of an elevated structure, this equipment can be positioned at the forefront of the plant, enabling the subsequent treatment phase to proceed without the need for additional pumping.

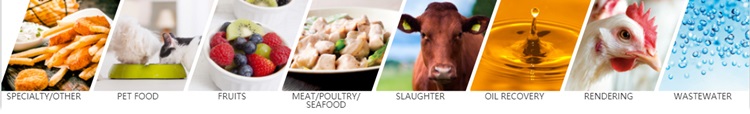

Static screen wastewater application

MUNICIPAL

The Merit Filter Corporation Static Screen is most commonly used for the primary treatment of raw sewage and/or combined storm water pretreatment.

Pretreatment removes most of the settleable solids and non-biodegradable floatables.

The Merit Static Screen can:

Remove up to 30% of suspended solids

Increase DO levels by 1 to 3 mg/L

Replace a comminutor at the headworks

Reduce BOD levels by 15 to 35%

Remove floatable by up to 90%

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China