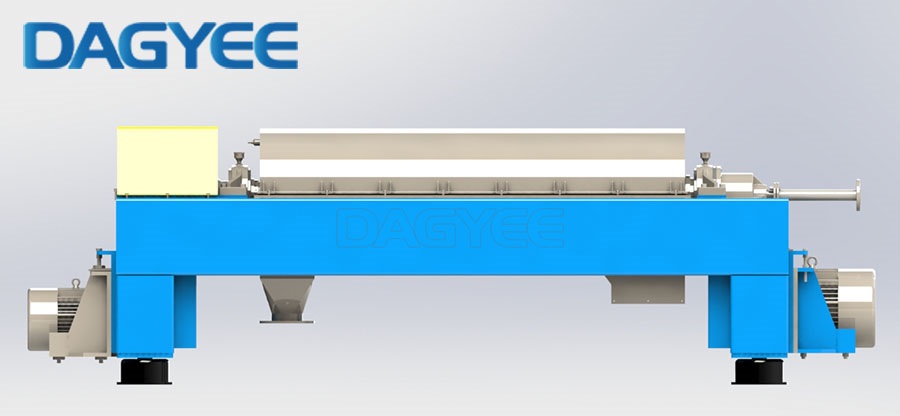

Decanter centrifuge descriptions

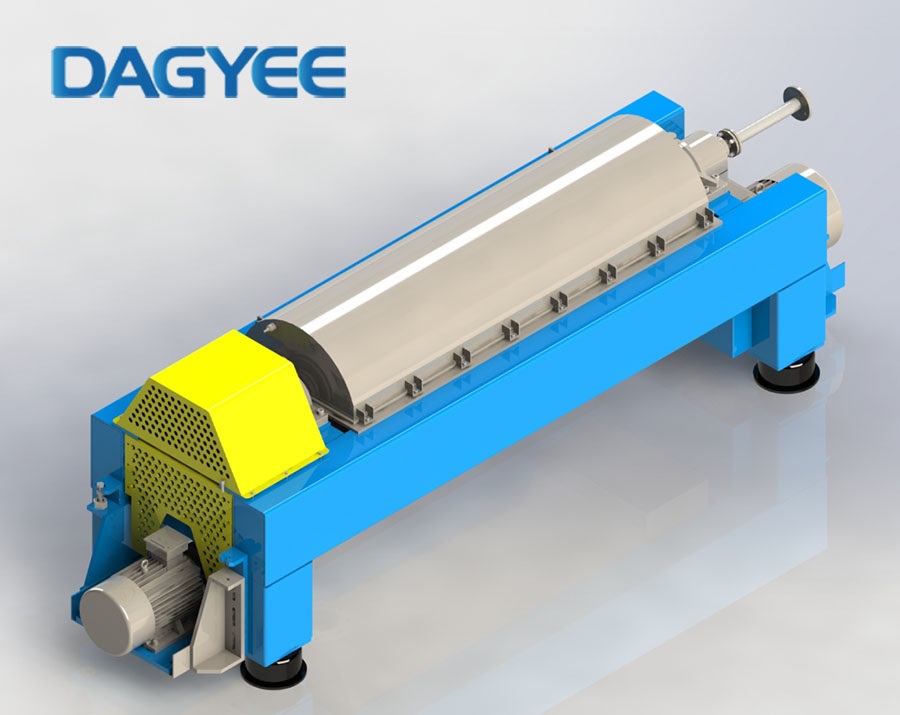

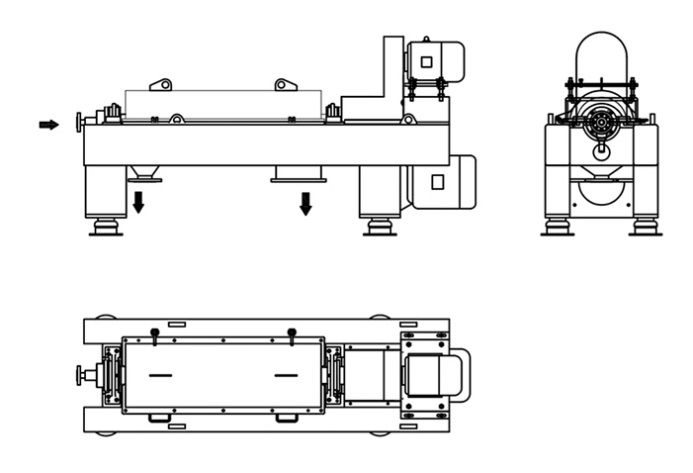

The horizontal decanter centrifuge, also known as a horizontal spiral centrifuge, is a settling device that operates continuously and unloads using a screw. In general, it features a compact structure, continuous operation, smooth running, strong adaptability, large production capacity, easy maintenance, and excellent dewatering effects. Therefore, its applications in the field of environmental protection are becoming increasingly widespread.

Although different manufacturers may have different equipment structures, materials, specifications, and operating adjustment mechanisms for horizontal decanter centrifuges of different specifications or models, their basic equipment principles are similar. Taking the widely-used Alfa Laval equipment as an example, let's provide a simple introduction to facilitate better use and adjustment for on-site users.

How does a decanter centrifuge work?

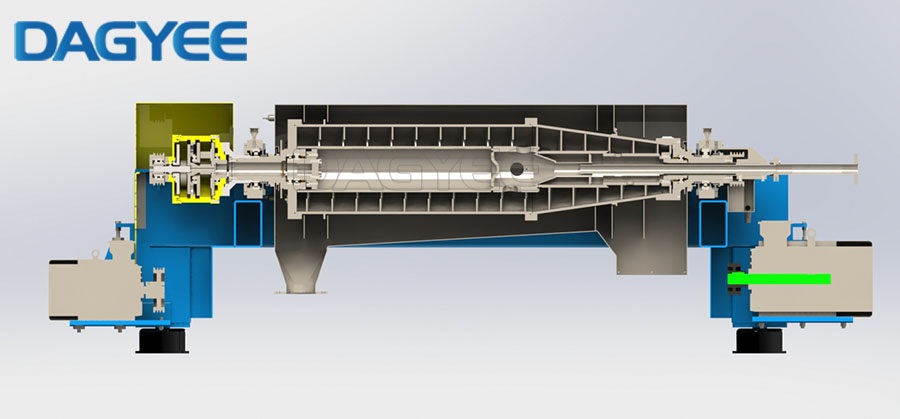

The work principle of a screw decanter centrifuge is based on the principles of sedimentation and centrifugal force. It involves the rotation of a bowl and a screw conveyor within the centrifuge to separate solid particles from liquids. Here’s a general overview of how the machine works:

Feed Introduction

The feed, which is a mixture of solid and liquid, is introduced into the centrifuge through an inlet pipe. The feed enters the rotating bowl of the centrifuge.

Sedimentation

As the feed enters the bowl, the high-speed rotation of the centrifuge generates centrifugal force. This force causes the solid particles in the feed to settle against the bowl wall due to their higher density. Meanwhile, the liquid phase, which has a lower density, forms a clear layer above the settled solids.

Screw Conveyor Operation

Inside the bowl, there is a screw conveyor that rotates at a different speed than the bowl itself. The screw conveyor consists of several sections: the feed section, the clarification section, and the dewatering section.

Solid Conveyance

The screw conveyor, rotating at a slightly lower speed than the bowl, moves the settled solids along the length of the bowl. The feed section of the screw conveyor collects the settled solids from the bowl’s wall and transports them towards the clarification section.

Clarification

In the clarification section of the screw conveyor, additional separation takes place. The solids continue to settle, and any remaining liquid is forced out through small openings in the conveyor. This allows further liquid-solid separation as the liquid passes through the openings while the solids are conveyed forward.

Dewatering

In the dewatering section, the settled solids are progressively compressed and dewatered as they move closer to the discharge end of the centrifuge. The compression and reduced conveyor pitch in this section help increase the dewatering efficiency.

Discharge

At the discharge end, the dewatered solids are pushed out of the centrifuge through an outlet. The separated liquid, known as the centrate or filtrate, exits the centrifuge through a separate outlet.

This process of continuous sedimentation, solid conveyance, clarification, and dewatering allows the screw decanter centrifuge to achieve efficient separation of solids from liquids. The rotational speed, differential speed between the bowl and screw conveyor, and the design of the conveyor flighting all contribute to the effective operation of the centrifuge.

Decanter centrifuge advanced operation capabilities

Clarification

Clarification removes suspended solids from a liquid of lower density across a particle size range from 1 to 10,000 microns. By increasing centrifugal force, even submicron particles can be separated, making this process ideal for high-purity applications in chemicals, mining, and waste management.

Classifying

Through controlled reduction of residence time, the decanter achieves sharp separation cuts for particle-size classification down to the submicron range. This capability is essential for processes requiring precise particle distribution and custom engineering solutions.

Liquid/liquid separation

The efficiently separates immiscible liquid phases of different densities, with or without solids present. This is critical for oil recovery and industrial wastewater treatment, where mechanical dewatering and centrifugal separation reduce reprocessing and disposal costs.

Thickening

Fine solids separated from the liquid can be thickened in a hindered settling mode, utilizing the cylindrical section of the bowl for maximum compression. This improves solids handling and reduces downstream load, contributing to operational efficiency.

Compression and dewatering

Compactive dewatering combines drainage and compression to achieve a higher degree of dryness, even with compressible solids. The degree of dewatering depends on solids characteristics, machine settings, and required dryness levels. Optimized conveyor and cone geometry, along with differential speed control, ensure stable discharge of pasty or shear-sensitive solids—key for waste management and cost reduction.

Counter-current washing

Integrated washing systems allow efficient, cost-effective removal of contaminants by separate discharge of wash liquor over multiple sections. This reduces chemical and water consumption, aligning with sustainability and process optimization goals.

Mixing and re-suspension

Special discharge geometries enable solids to be mixed with liquid directly at the outlet, eliminating the need for additional mixing vessels. This feature simplifies plant design and enhances operational efficiency.

Automation and innovation

Control systems for smart operation

Control systems stabilize separation quality, automate setpoints, and provide diagnostics that support predictive service strategies. As the “brain” behind the process, strengthens industrial automation and helps maintain equipment reliability through better visibility, alarms, and optimization tools.

Engineered for tough conditions

A broad choice of materials of construction, wear protection, and sealing options extends service life in abrasive or corrosive duties. Features like CIP, optimized bearings and seals, and gas-tight/pressurized casings are designed to lower maintenance effort while keeping performance high.

Options that boost performance

Depending on application, It can be equipped with energy-recovery weir plates, specialized feed systems to reduce particle breakage, and multiple drive/gearbox configurations—each selected to match duty conditions and performance targets.

Decanter centrifuge specifications

| Model |

Drum diameter mm |

Length mm |

Maximum speed rpm |

Highest separation factor g |

Mixture capacity m³/h |

|---|---|---|---|---|---|

| LW250-900 | 250 | 900 | 5000 | 3500 | 0.5-3 |

| LW350-1500 | 350 | 1500 | 3800 | 2850 | 1-5 |

| LW400-1200 | 400 | 1200 | 3400 | 2581 | 1-8 |

| LW400-1600 | 400 | 1600 | 3400 | 2581 | 2-10 |

| LW400-1800 | 400 | 1800 | 3400 | 2581 | 2-12 |

| LW450-1800 | 450 | 1800 | 3200 | 2572 | 5-20 |

| LW450-2000 | 450 | 2000 | 3200 | 2572 | 5-25 |

| LW530-2280 | 530 | 2280 | 2800 | 2350 | 10-50 |

| LW600-2400 | 600 | 2400 | 2600 | 2265 | 15-65 |

| LW650-2600 | 650 | 2600 | 2400 | 2100 | 20-80 |

| LW720-2500 | 720 | 2500 | 2200 | 1950 | 25-90 |

| LW800-2560 | 800 | 2560 | 2000 | 1800 | 30-100 |

| LW800-3200 | 800 | 3200 | 2000 | 1800 | 30-110 |

| LW900-3200 | 800 | 3200 | 1800 | 1650 | 30-150 |

Why choose the DAGYEE decanter centrifuge?/Decanter centrifuge advantages

1. High-Efficiency Separation with Strong Processing Capacity

The Horizontal Decanter Centrifuge can separate large volumes of mixtures in a short time, especially suitable for high-concentration and high-viscosity materials. Its continuous working mode significantly improves production efficiency, making it an ideal replacement for traditional filtration equipment.

2. High Automation Level and Easy Operation

Modern Horizontal Decanter Centrifuges are typically equipped with intelligent control systems, enabling automated operation. Users only need to set parameters, and the device can automatically complete the separation and discharge processes, greatly reducing the difficulty and cost of manual operation.

3. Strong Adaptability and Wide Application Range

The Horizontal Decanter Centrifuge is suitable for separating various materials, whether it’s suspensions in the chemical industry, slurries in the food industry, or sludge treatment in the environmental protection field. Additionally, the equipment can be customized based on different material characteristics to meet diverse production needs.

4. Energy-Saving, Environmentally Friendly, and Low Operating Costs

The Horizontal Decanter Centrifuge adopts efficient separation technology, achieving high output with low energy consumption. At the same time, its enclosed design effectively reduces material leakage and environmental pollution, aligning with the green production philosophy of modern industry.

Decanter centrifuge key features

Decanter Centrifuges allow separation between heavy liquid phase / light liquid phase and solid phases contained within a feed-slurry of industrial or municipal wastewater sludges or other industrial and/or food applications.

The feed slurry is introduced through an inlet feed tube into the scroll feed zone where it is accelerated and directed into the spinning bowl of the decanter centrifuge.

The solids which have a higher specific gravity than the liquid phase will rapidly settle out on the inner wall of the centrifuge bowl due to the intense acceleration of centrifugal force over 3,000 x “gravity” leaving a clear inner ring liquid phase.

The liquid phase flows in a helical channel between the scroll flights moving toward the large diameter end of the centrifuge bowl where the clarified heavy liquid phase is expelled at a depth controlled by the adjustable liquid level discharge plates on the outlet diameter of the liquid end head-wall.

The Light liquid phase is expelled separately from bowl through adjustable depth nozzles.

Both liquid “centrate” phases then overflows into their respective liquid discharge covers and gravity drain from the machine.

The compacted solid phase is discharged from the decanter centrifuge bowl by scroll which rotates at slightly different speed (differential speed) as controlled by the back-drive conveying the solids up the conical bowl section to the discharge ports.

The dry solids are discharged into the solids discharge cover where a solids scrapper keeps the cover clear of solids cake build-up.

Decanter centrifuge applications

The decanting centrifuges are the ideal tool in various fields:

Food:

The centrifuges developed for this sector are high performance centrifuges that meet the specific requirements of the industry. They have a high production efficiency and constant production quality levels. They can also be set up for the CIP cycle (Cleaning in Place) for complete sanitizing of the machine.

The separation of low density liquids with solids sized from 1 to 10,000 is carried out with an appropriate combination of the cylindrical section configuration, bowl speed, speed and configuration of the conveyor and, finally, the internal level of the liquid.

The horizontal centrifuges are used for the production of all types of fruit juices (grape, apple, lemon, etc.), for the production of tea or coffee, beer and wine.

Here, in detail, the different areas of use:

• in the production of fruit and vegetable juices, the decanter centrifuge succeeds in squeezing the previously ground fruit and vegetables to the highest possible level, obtaining a high yield of juice;

• in the production of soy and rice milk, the decanter centrifuge effectively separates the solids from all the cooking liquid obtaining a product free from impurities;

• in the production of cheese the decanter is used for the thickening and dewatering of the sludge;

• in distilleries, the use of the decanter ensures a really high dry substance content compared to the discharged solid, with a reduction in drying costs;

• in the clarification of the beer, through a centrifugation carried out before the filtering phase, the work carried out by the plant is reduced and it is possible to reduce the consumption of fossil flour at the origin;

• recovery of the grey starch from water used while cutting potatoes.

Waste treatment:

• the decanting centrifuges are used for the purification of water, including wastewater and municipal sludge: through a process of dehydration it is in fact possible to separate liquids from the solid phase obtaining a result of exceptional quality;

• the decanters allow the recovery of the paper: after it has been sent for recycling, a washing and a maceration bath are carried out; once this phase is finished, the liquid is separated from the solid part with a decanter centrifuge and then used as a basic material for the production of recycled paper;

• with the decanting centrifuges it is possible, through appropriate treatments, to recover the biogas produced by the fermentation of the organic fraction of the garbage to produce the biomethane.

Pharmaceutical area:

• the horizontal centrifuges perform a remarkable variety of separation processes with a high quality result, so they are ideal for the production of antibiotics, vitamins, dyes, active ingredients, etc.

Chemical area:

• the models with Espey mechanical seals are able to process suspensions with flammable and / or explosive liquids with ATEX certification, as required for example in the oil field, working in a controlled environment with a nitrogen atmosphere;

• they allow the separation of the Slop Oil and the recovery of the lagoon oils

Materials

The horizontal centrifuges allow to work a series of materials in different areas of industrial production.

Here are some examples of the most common use:

• paint sludge: the decanters separate the chromatic pigments from the liquid, allowing it to be recycled

• oily muds: the muds of lagoons and the tanks sludges can be purified by separating the different liquids present with a centrifuge; similar interventions can also be envisaged for refinery residues

• sludge from steel mills: the centrifuges are used for the sludge dehydration deriving from the abatement processes of the powders of the gas produced in the blast furnace, the concentration of sludge deriving from the cold rolling mills and the dehydration of sludge from superficial encrustations of the laminae

• PVC and polyethylene: for the separation of polymers and mother liquor (aqueous suspension PVC, polyethylene of organic solvents)

• rendering: using the centrifuges it is possible to produce animal fats and proteins effectively and with a low cost

• vegetable proteins: decanters have a great importance in the processes for the extraction of vegetable proteins

• fermentation decoctions: here they are used for the separation of biological mass

Contact us:

Company: Wuxi Dajiang Environmental Technology Co., Ltd. DAGYEE

Phone/WhatsApp:+8613961861780

Email: info@dagyee.com

Website: www.dagyee.com

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China