Static screen wastewater description

The Hydro-Static Screen offers an economically sustainable screen for combined sewer overflow (CSO) sites with infrequent overflows, but at which environmental protection is

still a concern.

A non-powered screening technology, the Hydro-Static Screen provides effective gross solids and floatables capture and works with small flows and small budgets.

The Hydro-Static Screen is available in two configurations, either as an Up-Flow screen or a weir-mounted Through-Flow screen.

With no moving parts and flow-modifying components in the Up-Flow configuration to provide partial cleaning, maintenance is kept to a minimum.

To protect against corrosion components are typically supplied in grade 304 stainless steel as standard, and the mesh screen panels are coated in a non-stick polymer to reduce blinding.

Static screen wastewater works

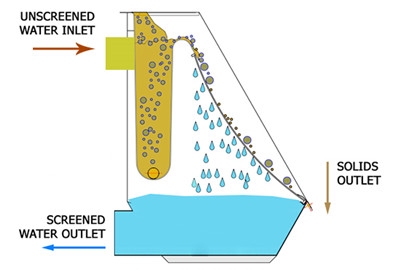

The mixture is pumped and distributed along a horizontaloverflow in order to use of the entire width of the sieve.

Once it is in contact with the sieve, the solution is stronglyaccelerated by the steep angle of the sieve, which initiates theseparation of the solid particles contained in the liquid.

The waterpasses through the slots in the sieve and falls to the base of theunit, while the solid particles are carried towards the bottom of thesieve.

Static screen wastewater model

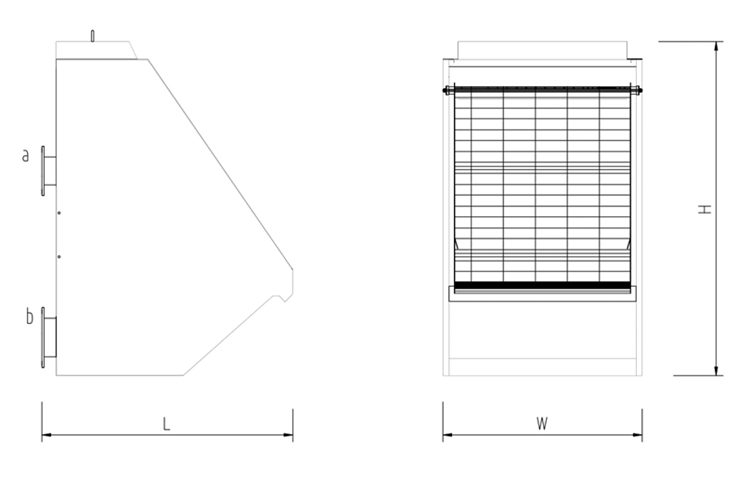

| HS Model |

Piping Connections Inlet(a) | Effluent(b) |

Physical Dimensions(m) L | W | H |

Weight (Kg) |

Capacities(m³/h) 0.5mm | 1mm | 1.5mm |

|---|---|---|---|---|

| HS-300 | 80 | 80 | 1.43 | 0.43 | 2 | 150 | 6 | 13 | 16 |

| HS-500 | 100 | 100 | 1.43 | 0.63 | 2 | 180 | 10 | 22 | 35 |

| HS-700 | 100 | 100 | 1.43 | 0.83 | 2 | 200 | 15 | 30 | 50 |

| HS-800 | 100 | 125 | 1.43 | 0.93 | 2 | 250 | 16 | 35 | 55 |

| HS-1000 | 150 | 150 | 1.43 | 1.13 | 2 | 280 | 20 | 45 | 70 |

| HS-1500 | 150 | 150 | 1.43 | 1.63 | 2 | 300 | 30 | 65 | 100 |

| HS-2000 | 200 | 200 | 1.43 | 2.13 | 2 | 400 | 40 | 75 | 120 |

Static screen wastewater advantage

1. No moving parts, no motor.

2. Very low installation costs, no maintenance.

3. Only requires periodic cleaning.

4. Quiet operation.

5. Wave shape of the bars provides the HydraSieve screen with its self-cleaning effect.

Static screen wastewater feature

The DAGYEE Static Screen offers a low cost and dependable solution for the removal of suspended solids from municipal and industrial wastewater streams.

The DAGYEE Static Screen is stationary, requires no power to operate and has no moving parts, thus making it the most economical method of screening and classifying

wastewater streams.

The DAGYEE Static Screen is self-cleaning requiring minimal operator maintenance or input.

It is compact, highly reliable and easily installed.

The DAGYEE Static Screen can pay for itself in a short time by reducing treatment costs and recovering valuable by-products.

By using the DAGYEE Static Screen for primary screening the organic loading on a wastewater plant is reduced, thereby reducing loading and maintenance on digesters, clarifiers,

lagoons and pumps.

It may also allow piping size to be reduced, by reducing volume into the plant.

Thus, the DAGYEE Static Screen will improve overall efficiency of the waste treatment system.

The DAGYEE Static Screen is constructed entirely of Type 304 stainless steel for maximum durability and is available in Type 316 stainless steel.

Available to handle flows from 10 GPM up to 1.0 MGD in a single unit. Units may be “ganged” together to handle higher flows.

Slot size can range from 0.010″ (1/4 mm) up to 0.100″ ( 2 1/4 mm).

Standard sizes range from 2 feet wide to 6 feet wide.

Static screen wastewater application

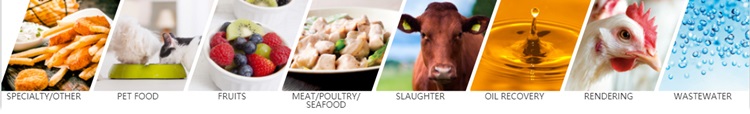

Environment: Domestic sewage / Storm water screening / Wash water from sand filters / Sewer cleaning tasks / Screening industrial intake water / Screening fire sprinkler water / Pig manure / Textiles and laundries

Food: Fruit and vegetable canning / Wine producers and distilleries / Meat and processed meals industry / Slaughterhouse / Fish processing / Breweries and dairies

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China