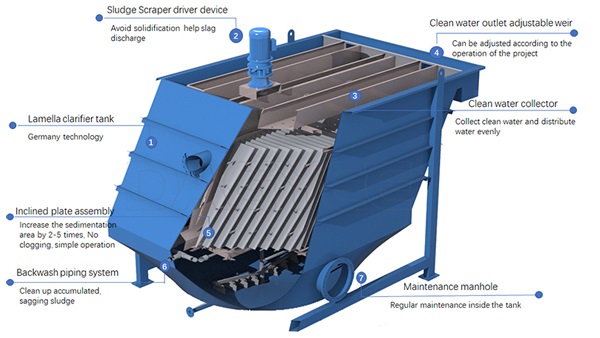

The DAGYEE Lamella Clarifier is designed to provide low cost, efficient solids removal from a wide range of waste and process liquids. The inclined plate design allows the total gravity settling area to be as much as ten times more than the actual floor space occupied by the clarifier. Integral chemical mixing and flocculation tanks are available, as well as options for enhanced sludge thickening.

The Flash Mix and Flocculation Tanks (optional) allow for the addition of chemicals and polymers that will aid the settling process — adjusting pH to precipitate dissolved solids and/or enhancing the agglomeration of suspended particles into heavier, more settle-able floc. The liquid is fed from these tanks into the clarifier through the inlet chamber, which directs flow into the separation section.

The liquid then enters the lower area of the laminar plates through side slots which distribute it across the entire width of the plates. Particulate settles onto the face of the plates and slides down to the clarifier bottom. The clarified liquid exits the plate sections through weirs at the top of the unit which are designed to develop and control adequate pressure drop, maintaining laminar flow through the plates. The clarified liquid then flows into the effluent chamber and out of the clarifier.

Lamella clarifier available options

• Flash mixing/flocculation tank with agitator

• Full glass steel or stainless steel structure

• Concrete tank design

• Special coatings and plates

• Integrated mechanical sludge thickener

• Overhaul platforms and ladders

• In-house laboratory analysis to optimize equipment

• Drinking water design

• Gasket and removable cover

• Automatic desilting

• Instrumentation and control

• Chemical feed equipment

• Sludge treatment and dewatering

• Pilot size units for field testing

Lamella clarifier model

DLC-I Gravity Lamella ,V shape mud bucket, simple structure, no energy consumption.

DLC-II Lamella with scraper,Increase the mechanical transmission mechanism, the mud discharge is better and smoother, and it matches the unit with large processing capacity.

DLC-III Super hydraulic Lamella,Reduced footprint, efficient sedimentation, detachable transportation.

| DLC Model | Capacities (m³/h) | Piping Connections (mm) | Physical Dimensions (m) | |||||

|---|---|---|---|---|---|---|---|---|

| Inlet(a) | Effluent(b) | Sludge(c) | Backwash(d) | L | W | H | ||

| DLC 5 | 5 | 80 | 80 | 50 | 50 | 2.55 | 1.6 | 2.9 |

| DLC 10 | 10 | 100 | 100 | 50 | 50 | 3.35 | 1.82 | 3 |

| DLC 15 | 15 | 100 | 100 | 50 | 50 | 3.35 | 2.02 | 3 |

| DLC 20 | 20 | 100 | 100 | 50 | 50 | 3.35 | 2.02 | 3 |

| DLC 30 | 30 | 150 | 150 | 50 | 50 | 4.2 | 2.22 | 3 |

| DLC 40 | 40 | 150 | 150 | 50 | 50 | 4 | 2.8 | 3 |

| DLC 50 | 50 | 200 | 200 | 50 | 50 | 4.65 | 2.82 | 3 |

| DLC 60 | 60 | 200 | 200 | 50 | 50 | 4.7 | 3 | 3 |

| DLC 70 | 70 | 250 | 200 | 50 | 50 | 6.4 | 2.6 | 3 |

| DLC 80 | 80 | 250 | 200 | 50 | 50 | 6.8 | 2.82 | 3 |

| DLC 100 | 100 | 250 | 250 | 50 | 50 | 7.05 | 3.02 | 3 |

1. Lamella clarifiers utilize sedimentation to efficiently separate solids from wastewater.

2. Their compact, inclined plate design allows for effective treatment within a small space.

3. They are pivotal in meeting industry standards and environmental regulations for wastewater disposal.

Lamella clarifiers are characterized by their stacked plate design and sludge collection mechanisms. The compact arrangement allows for a high rate of clarification in a small space. During operation, a steady flow of wastewater enters the clarifier and distributes evenly across the plates, maximizing the use of available area for particle settling.

By utilizing inclined plates, lamella clarifiers increase the effective settling area for particle removal. This design attribute enables a quicker and more effective separation process compared to traditional horizontal settlers. Due to this, they can achieve:

1. Higher flow rates

2. Improved effluent quality

3. Greater operational flexibility

Moreover, their modular nature allows for ease of installation and expansion to accommodate varying treatment capacities. The presence of lamella technology in wastewater treatment underscores the continued innovation towards more efficient and space-saving solutions in environmental management.

Lamella clarifier application

Contact Us for a Consultation

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China