Externally rotary fed drum screen description

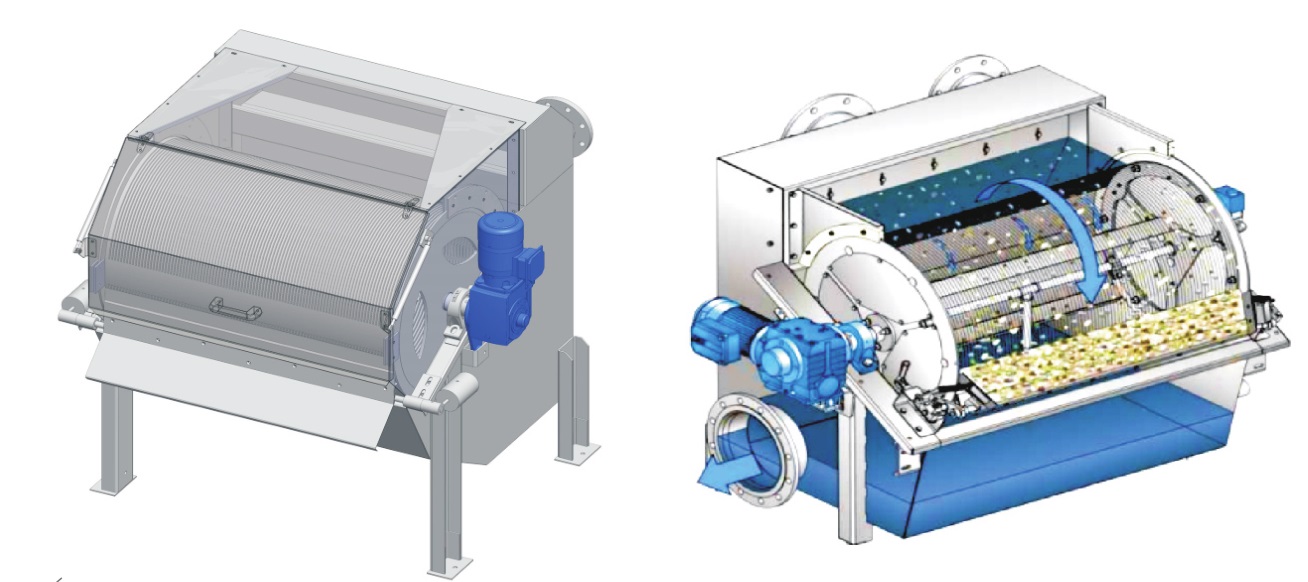

This stainless steel wedge wire screen is self-cleaning by nature due to constant back washing.

This often allows for only intermittent use of the spray bar cleaning system, reducing water usage.

Not well suited for fine screening of high flows, but the use of the doctor blade system makes this mechanical screen well suited when oils and grease are present.

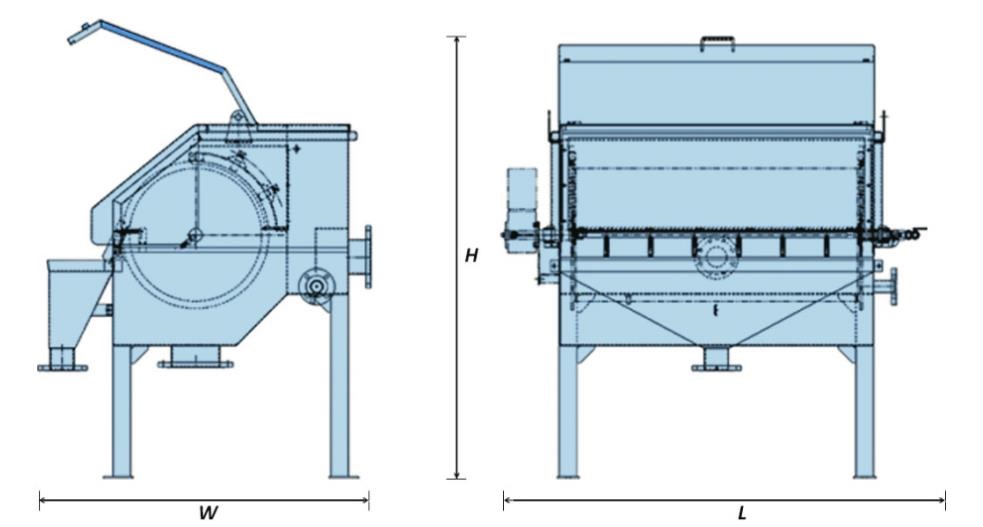

Sized based on peak flow, solids and fats, oils, grease loadings in the wastewater/process water, these units can be configured with a variety of piping scenarios, overall dimensions and slot openings.

Bypass configurations allow for bypass of overflow when upset conditions occur.

Externally rotary fed drum screen function

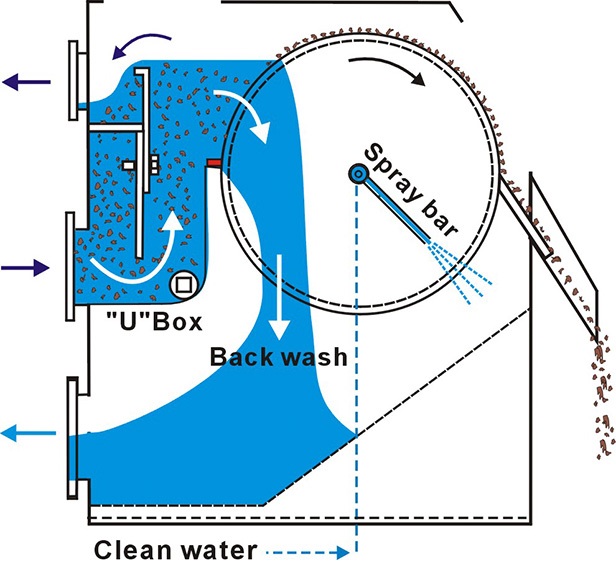

The AC speed motor drives the grid cylinder through the reducer, and the sewage passes through the inlet valve to the water tank and rises to the filter water level through the uniformly distributed box plate.

The water enters the cylinder through the gap of the grid and is discharged from the bottom of the grid cylinder,and cleans the grid.

The impurities and fibrous organic substances larger than the grid gap are blocked by the grid and carried to the other side of the cylinder by the rotating grid cylinder.

After being discharged by the unloader to the slag hopper, the water content of the treated garbage is lower than 30%-50% than the original equipment.

The filtered sewage flows into the outlet tank and is discharged through the drain.

Externally rotary fed drum screen model

| Industry Type | Slot (mm) | RDS03/300 | RDS06/400 | RDS06/700 | RDS06/1000 | RDS06/1300 | RDS06/1600 | RDS08/2000 | RDS08/2500 |

|---|---|---|---|---|---|---|---|---|---|

| Paper Industry | 0.5 | 6 | 20 | 40 | 60 | 80 | 100 | 130 | 190 |

| Slaughter House | 0.5 | 4 | 15 | 30 | 45 | 60 | 75 | 95 | 130 |

| Seafood Industry | 0.75 | 5 | 17 | 35 | 50 | 70 | 90 | 110 | 140 |

| Meat Industry | 0.75 | 6 | 20.5 | 40 | 60 | 80 | 100 | 130 | 190 |

| Meat Industry | 1.0 | 7.5 | 25 | 50 | 75 | 100 | 125 | 150 | 220 |

| Vegetable Industry | 1.0 | 12 | 40 | 75 | 110 | 150 | 180 | 220 | 330 |

Externally rotary fed drum screen advantage

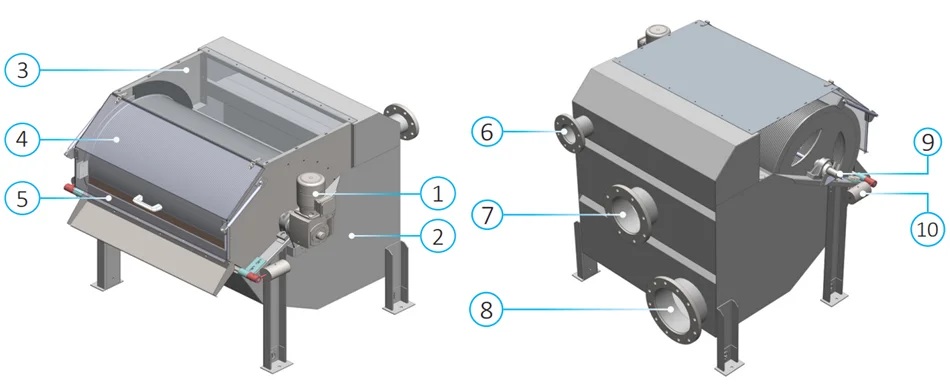

1. Slot width: 0.25 - 2.5mm.

2. Wedge wire filter with so called ‘slot zero’ to ensure drum resistance.

3. Screen manufactured from 304 L / 316 L SS.

4. Overflow (optional).

5. Fixed drum washing system with high pressure water pre-arrangement (optional).

6. Cleaning blade as an alternative to brass blade.

7. Control panel (optional).

Externally rotary fed drum screen feature

Rotating Drum

The drum consists of perforated plates or wedge wires screen.

Self-Cleaning

Self-cleaning system consisting of many nozzles placed in the rotating drum to clean the system.

Scraper Blade

The drum is cleaned by means of a scraper plate.

Externally rotary fed drum screen application

Food Industry, Starch & Gluten removal, Solids from wash water e.g. restaurant wastewater, Sugar cane juice, sugar beet tailings, and potato waste. Etc.

Pet food Industry, Recovery of raw materials, separation of solids from wash down water for reuse of the water and materials.

Significant Savings in water bills, wastewater treatment and more efficient use of the raw materials.

Pulp & Paper IndustryWood Chip/Sawdust removal Paper & Pulp from wash water.

Brewing & Soft Drinks IndustryTroup removal & effluent screening, fruit juice separation.

Water Treatment IndustryScreenings removal, Grit removal, and Effluent treatment.

Sewage Treatment IndustryPrimary & Secondary Screening.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China