Externally rotary fed drum screen description

Externally fed drum screen provides advanced solids removal for wastewater treatment, specifically designed for municipal and industrial facilities.

Its durable stainless steel structure and automatic self-cleaning mechanism offer reliable, low-maintenance performance, effectively handling solids separation under demanding conditions.

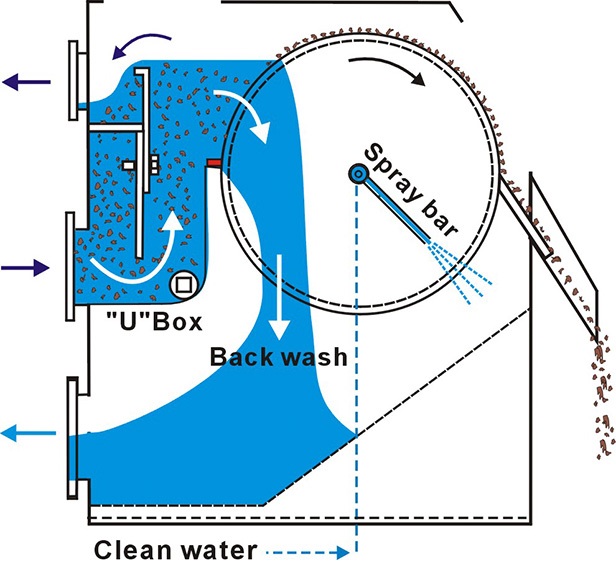

Influent flows evenly across the rotating drum surface, capturing solids on the exterior screen while filtered water passes through.

Continuous drum rotation and internal spray cleaning prevent clogging, delivering uninterrupted operation.

The compact, enclosed design minimizes odor, reduces maintenance needs, and optimizes overall treatment efficiency.

Externally rotary fed drum screen function

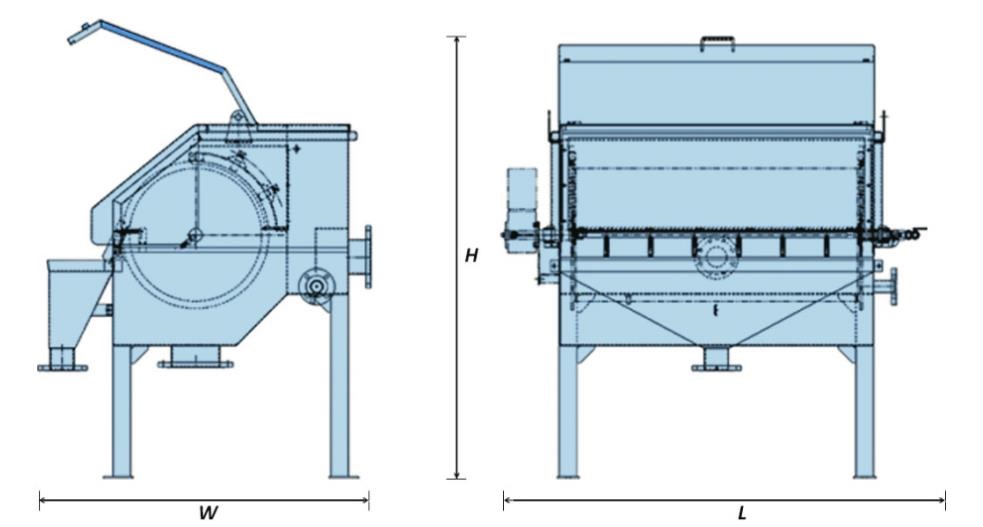

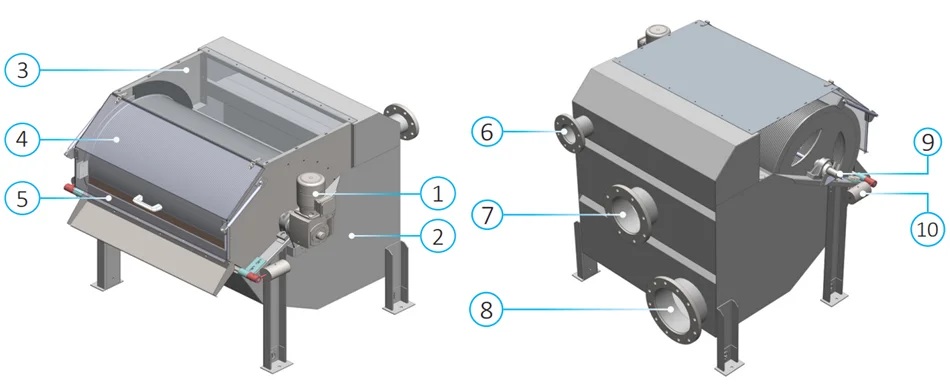

The EXTERNALLY FED DRUM SCREEN is composed of a case made up of stainless steel plate and section bars.

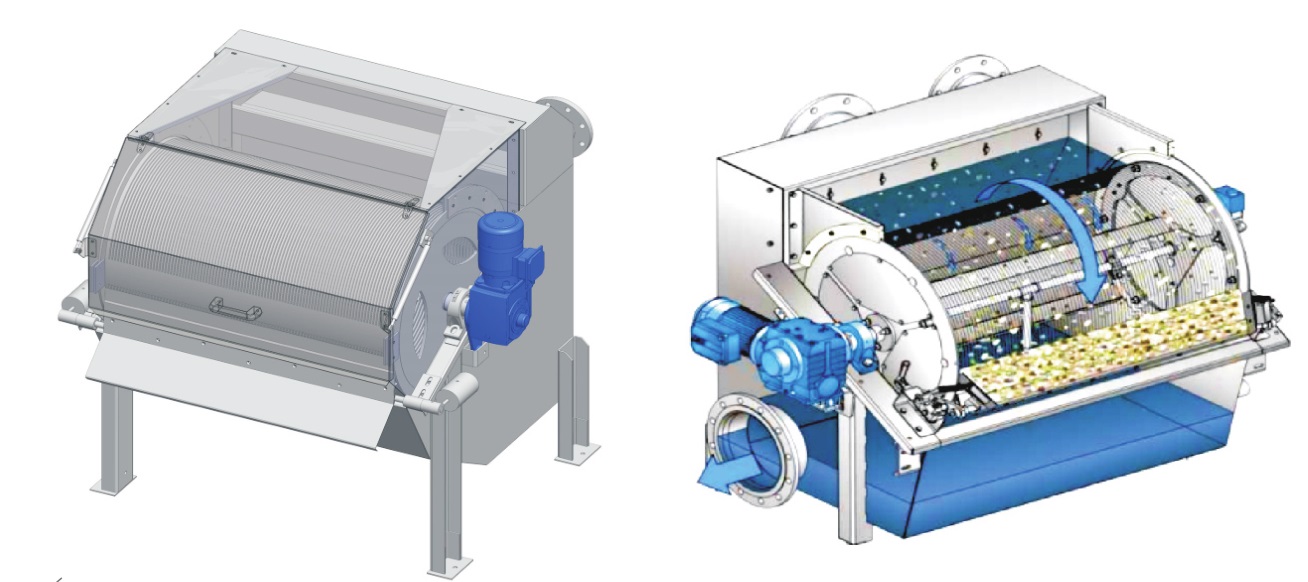

The stainless steel filter, whose surface is made up of a stainless steel “V” profile wedge wire tipe winded up as a spiral, rotates inside the case.

The distance between each coil is the same as the desired filtering slot.

The liquids to be filtered flow in the feeding tank through a flanged inlet and are conveyed on the filter surface through a special distributor equipped with wet seal.

The solids separation occurs there: the solids are kept and made to rotate by the external surface of the rotating filter, and, finally, discharged by a brass cleaning blade.

The liquid filtered passes through the filtering drum, where it is washed again on the opposite side of the filter, conveyed on the tank bottom and then discharged.

The filter rotates thanks to a bath oil gearbox directly connected at the rotating drum filter.

Inside the rotating filter there is or a washing system equipped with nozzles (mobile washing system), which work with high pressure water, or a bar composed of a set of spray nozzles (fixed washing system), through which the filtering drum can be periodically cleaned.

Externally rotary fed drum screen model

| Industry Type | Slot (mm) | RDS03/300 | RDS06/400 | RDS06/700 | RDS06/1000 | RDS06/1300 | RDS06/1600 | RDS08/2000 | RDS08/2500 |

|---|---|---|---|---|---|---|---|---|---|

| Paper Industry | 0.5 | 6 | 20 | 40 | 60 | 80 | 100 | 130 | 190 |

| Slaughter House | 0.5 | 4 | 15 | 30 | 45 | 60 | 75 | 95 | 130 |

| Seafood Industry | 0.75 | 5 | 17 | 35 | 50 | 70 | 90 | 110 | 140 |

| Meat Industry | 0.75 | 6 | 20.5 | 40 | 60 | 80 | 100 | 130 | 190 |

| Meat Industry | 1.0 | 7.5 | 25 | 50 | 75 | 100 | 125 | 150 | 220 |

| Vegetable Industry | 1.0 | 12 | 40 | 75 | 110 | 150 | 180 | 220 | 330 |

Externally rotary fed drum screen advantage

1. Compact design.

2. Easy to install in narrow spaces / aerial channels.

3. High flow rates.

4. Self cleaning.

5. User friendly.

6. Low energy consumption and limited maintenance

Externally rotary fed drum screen feature

It is made of high-strength and corrosion-resistant stainless steel, which has a small footprint and is convenient for construction.

It can be directly fixed with expansion bolts.

This device does not need to be grooved. Both inlet and outlet water can be connected by pipes.

The screen has an inverted trapezoidal cross-section and the filter screen will not be blocked.

It is controlled by a speed-regulating motor,which can keep it in good working condition according to the water flow.

The special washing device can brush off a small amount of impurities stuck on the surface of the grid.

After the barrel is internally washed twice, a good cleaning effect can be achieved.

At the same time, a washing device is set to remove the dirt stuck on the mesh.

Externally rotary fed drum screen application

Poultry and seafood processing

Industrial waste treatment system

Municipal waste treatment system

Snack and frozen food processing

Fruit and vegetables processing

Chemical processing

Brewing processing

Meat processing

Pulp & Paper Industrial processing

Tanning Industrial processing

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China