Externally rotary fed drum screen description

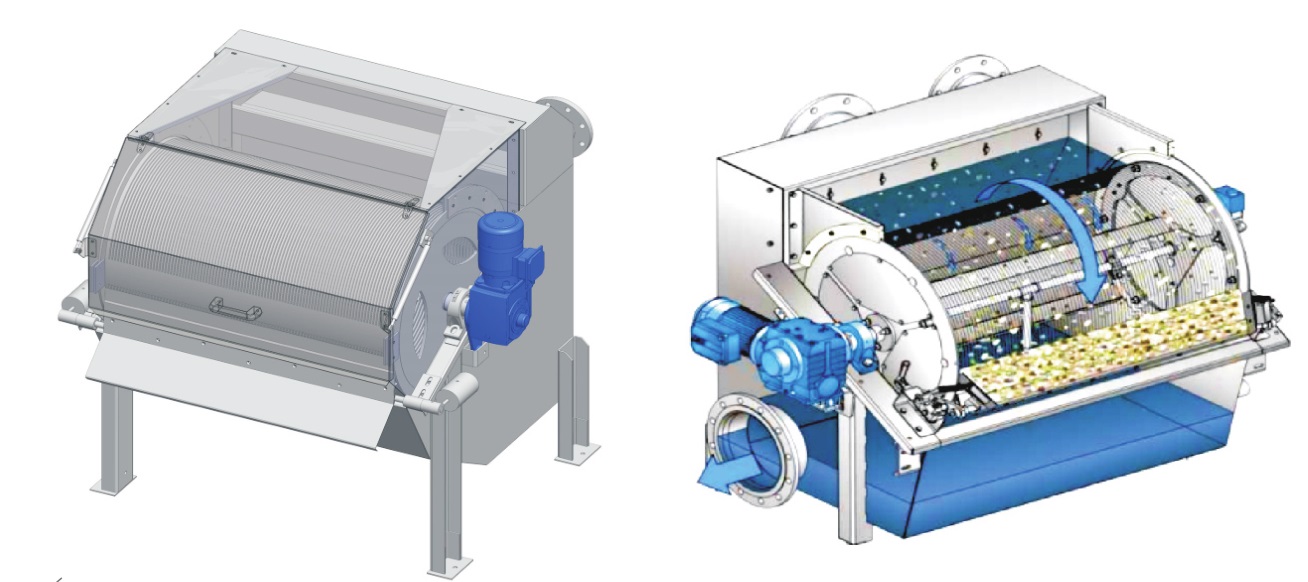

An externally fed rotary drum screen is a mechanical screening device where influent water flows over the external surface of a rotating drum.

As water passes through the screen, suspended solids are captured and carried away for disposal.

The clear liquid moves forward to the next treatment stage.

This simple yet effective design makes it ideal for solid-liquid separation in various wastewater treatment processes.

The drum screen surface can be made from wedge wire or perforated plate materials, offering flexibility depending on the type of solids to be removed.

An externally fed rotary drum screen is a mechanical screening device where influent water flows over the external surface of a rotating drum.

As water passes through the screen, suspended solids are captured and carried away for disposal.

The clear liquid moves forward to the next treatment stage.

This simple yet effective design makes it ideal for solid-liquid separation in various wastewater treatment processes.

The drum screen surface can be made from wedge wire or perforated plate materials, offering flexibility depending on the type of solids to be removed.

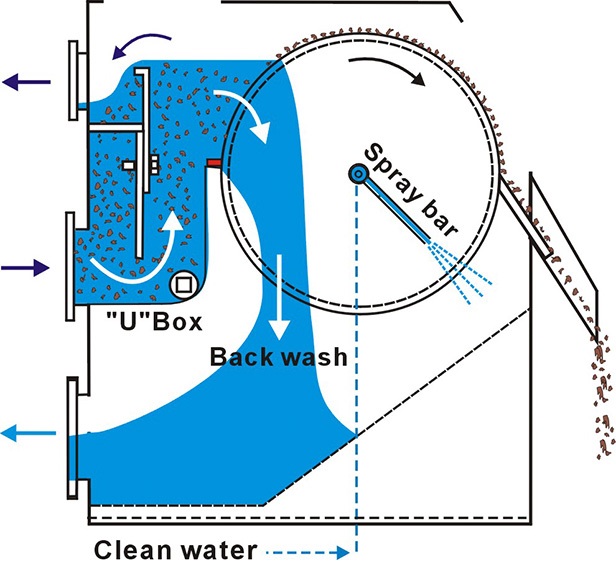

Externally rotary fed drum screen function

The screen is externally fed so that influent is directed under a baffle, then upward and over the length of the cylinder.

The natural action of wastewater cascading through the screen creates a powerful backwash, which results in a continuously clean surface.

Solids are caught on the outside of the screen surface and are removed by a tensioned doctor blade.

Opening sizes are available from 0.010" (.250 mm) to 0.100" (2.54 mm).

Capacities range from 60 GPM (13.6 M3/H) to 7800 GPM (1771 M3/H) in a single unit. Additional models are available to handle higher capacities.

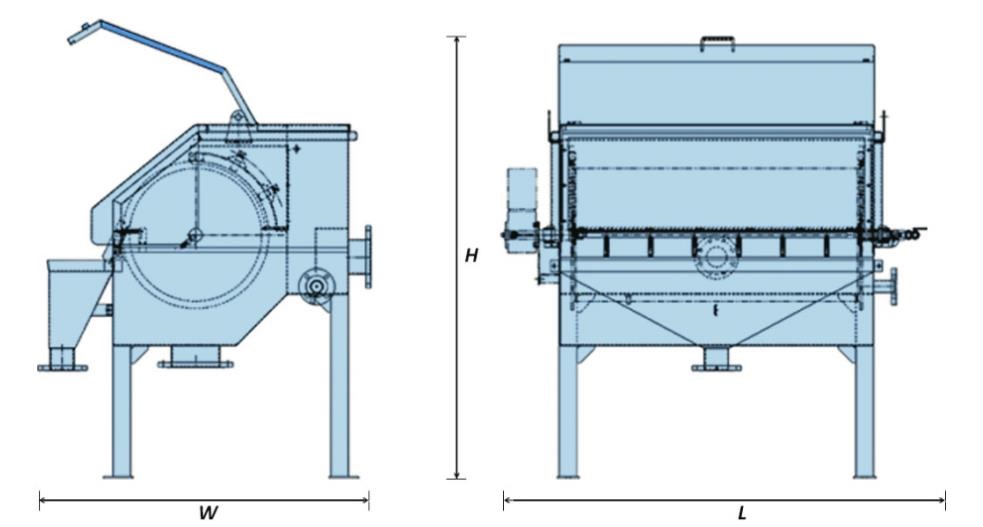

Externally rotary fed drum screen model

| Industry Type | Slot (mm) | RDS03/300 | RDS06/400 | RDS06/700 | RDS06/1000 | RDS06/1300 | RDS06/1600 | RDS08/2000 | RDS08/2500 |

|---|---|---|---|---|---|---|---|---|---|

| Paper Industry | 0.5 | 6 | 20 | 40 | 60 | 80 | 100 | 130 | 190 |

| Slaughter House | 0.5 | 4 | 15 | 30 | 45 | 60 | 75 | 95 | 130 |

| Seafood Industry | 0.75 | 5 | 17 | 35 | 50 | 70 | 90 | 110 | 140 |

| Meat Industry | 0.75 | 6 | 20.5 | 40 | 60 | 80 | 100 | 130 | 190 |

| Meat Industry | 1.0 | 7.5 | 25 | 50 | 75 | 100 | 125 | 150 | 220 |

| Vegetable Industry | 1.0 | 12 | 40 | 75 | 110 | 150 | 180 | 220 | 330 |

Externally rotary fed drum screen advantage

1. 100% overflow protection for designed flow up to 5.0 mgd.

2. More material recovery for re-use or improved industrial wastewater production.

3. Customized to fits into existing infrastructure.

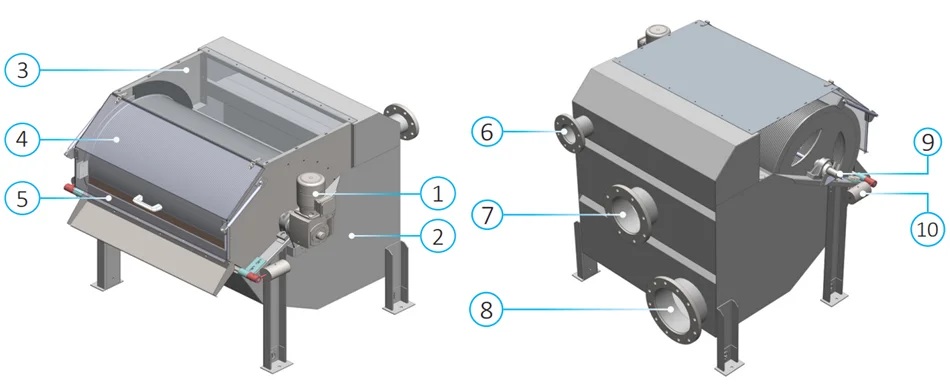

Externally rotary fed drum screen feature

1. Durable & Space-Saving Design

Made of high-strength, corrosion-resistant stainless steel. Requires minimal installation space and no channel construction.

Can be fixed directly with expansion bolts; inlet and outlet can be easily connected via pipes.

2. Non-Clogging Performance

The inverted trapezoidal cross-section of the screen prevents blockages caused by solid waste.

3. Smart Operation

Equipped with a variable-speed motor that adjusts automatically to water flow, maintaining optimal working conditions.

4. Self-Cleaning System

Features a specialized dual-brush cleaning system and external washing device, ensuring thorough cleaning and consistent screening efficiency.

Externally rotary fed drum screen application

This advanced solid-liquid separation device is designed for continuous and automatic removal of debris in wastewater treatment processes.

It is ideal for:

Municipal wastewater treatment plants

Residential and community sewage pretreatment systems

Pumping stations, waterworks, and power plants

Industrial wastewater treatment across sectors such as: textile, printing and dyeing, food processing, fishery, papermaking, winemaking, slaughterhouses, leather factories, and more.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China