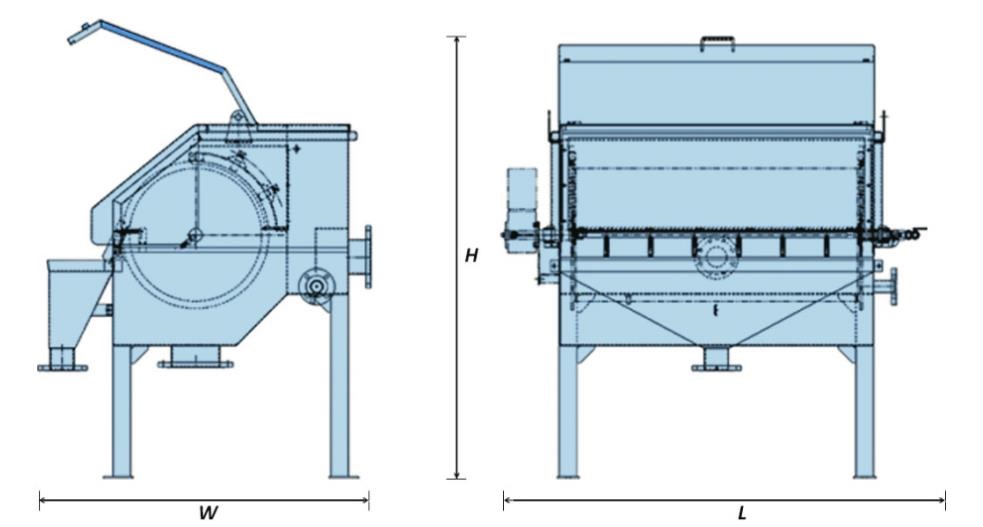

Externally rotary fed drum screen description

It is an externally fed rotary drum screen designed to provide efficient and reliable solids separation in a wide range of wastewater treatment applications.

Ideal for municipal headworks, industrial process water, and sludge screening, the unit delivers high-performance screening with minimal operator attention.

Its rugged stainless steel construction and enclosed, self-cleaning design ensure long-term durability and cleanliness, even in demanding environments.

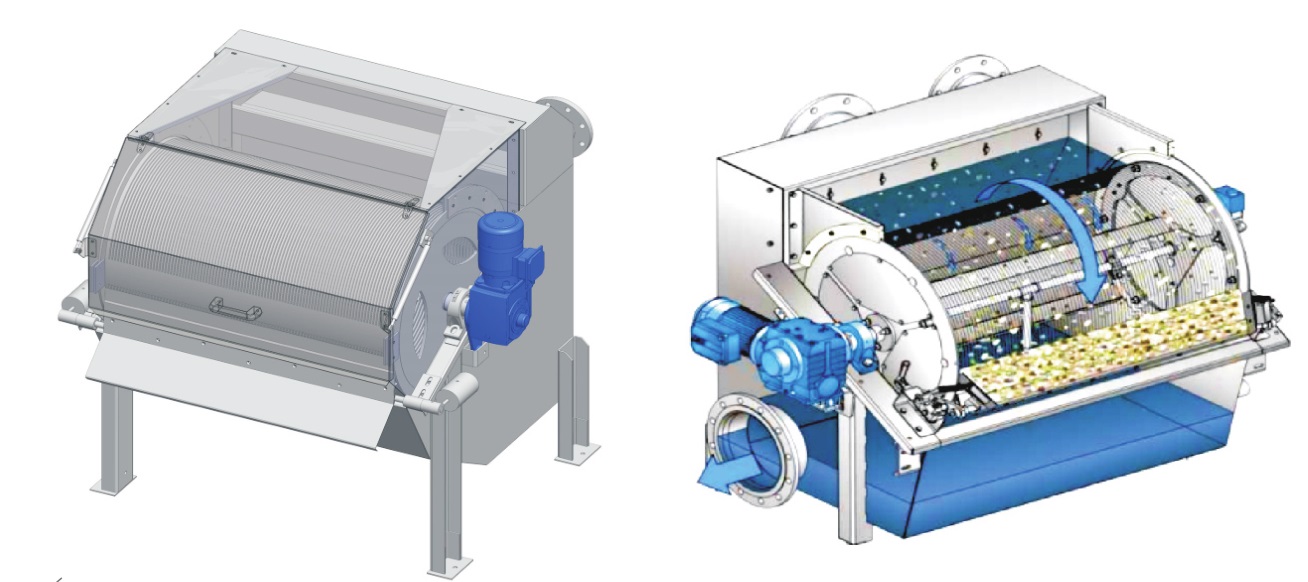

As wastewater flows over the drum’s exterior surface, solids are retained while liquid passes through the screen openings.

The rotating drum is continuously cleaned by an internal spray system, maintaining open screening surfaces and maximizing throughput.

The captured solids are conveyed to discharge, leaving screened effluent ready for downstream treatment.

With a compact footprint, customizable screen sizes, and low maintenance requirements, the Screenmaster ES offers a simple yet effective solution for enhancing plant efficiency and protecting downstream equipment.

Externally rotary fed drum screen function

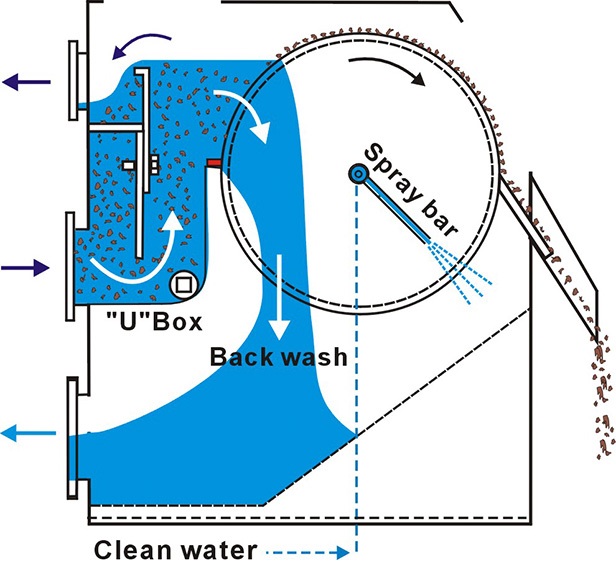

Raw influent enters a headbox which distributes the flow evenly across the full length of the rear, upper external surface of the rotating drum.

As water passes through the screen, solids are retained on the outside of the screen drum and are carried by rotation around to the front of the screen, where they are removed by a fixed doctor blade.

The screened water cascades down inside the drum and falls through the bottom, creating a vigorous backwash action.

This action, together with the use of internal water sprays, has a combined effect to self-clean the drum on every revolution.

Externally rotary fed drum screen model

| Industry Type | Slot (mm) | RDS03/300 | RDS06/400 | RDS06/700 | RDS06/1000 | RDS06/1300 | RDS06/1600 | RDS08/2000 | RDS08/2500 |

|---|---|---|---|---|---|---|---|---|---|

| Paper Industry | 0.5 | 6 | 20 | 40 | 60 | 80 | 100 | 130 | 190 |

| Slaughter House | 0.5 | 4 | 15 | 30 | 45 | 60 | 75 | 95 | 130 |

| Seafood Industry | 0.75 | 5 | 17 | 35 | 50 | 70 | 90 | 110 | 140 |

| Meat Industry | 0.75 | 6 | 20.5 | 40 | 60 | 80 | 100 | 130 | 190 |

| Meat Industry | 1.0 | 7.5 | 25 | 50 | 75 | 100 | 125 | 150 | 220 |

| Vegetable Industry | 1.0 | 12 | 40 | 75 | 110 | 150 | 180 | 220 | 330 |

Externally rotary fed drum screen advantage

1. Removal of the fine particles efficiently.

2. Automation with lifting pumps.

3. Long-lasting with stainless steel parts.

4. Energy saving.

5. Mobile compact desing.

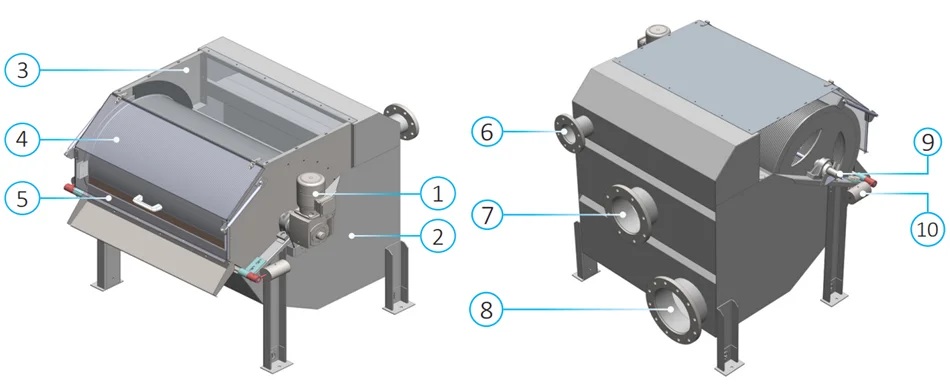

Externally rotary fed drum screen feature

1. Slot width: 0.25 ~ 2.50 mm.

2. Wedge wire filter with so-called “slot zero” to ensure drum resistance.

3. Screen in 304 L / 316 L SS.

Externally rotary fed drum screen application

This advanced solid-liquid separation device is designed for continuous and automatic removal of debris in wastewater treatment processes.

It is ideal for:

Municipal wastewater treatment plants

Residential and community sewage pretreatment systems

Pumping stations, waterworks, and power plants

Industrial wastewater treatment across sectors such as: textile, printing and dyeing, food processing, fishery, papermaking, winemaking, slaughterhouses, leather factories, and more.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China