Externally rotary fed drum screen description

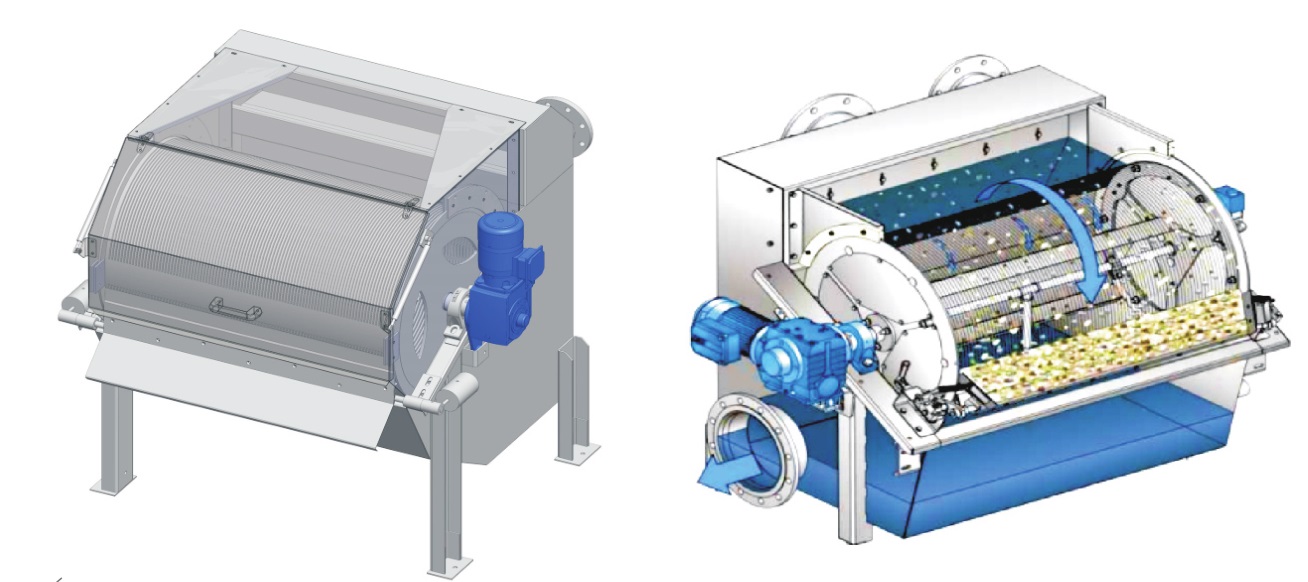

The Externally Fed Rotary Drum Screens is a highly reliable self-cleaning wedge wire screen that is recommended for use in both municipal and wastewater operations as well as several industrial screen applications.

This screening technology can perform very well in wastewater with heavy oil or grease loadings as well as scum applications that can blind other screen types.

Within the municipal wastewater, screens are used for fine screening primary sewage influent at the headworks and also as screening of clarifier scum.

The other industrial screen applications which commonly use the externally fed drum screens include poultry and meat processing, pulp, and paper debarking, seafood offal effluent, the drum screen is constructed slotted stainless wedge wire, cylindrical drums which rotate on two pillow block bearings.

The screen mainly has a lot of opening ranging. the feature-complete overflow protection from flows or blinding.

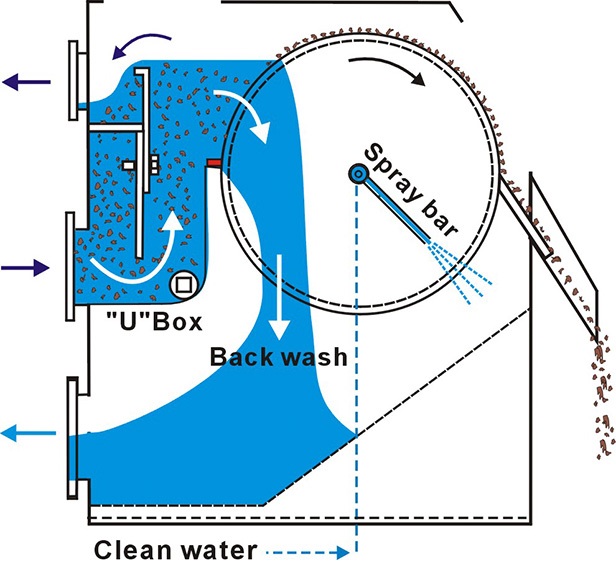

Externally rotary fed drum screen function

As speed regulating motor through a speed reducer drive reseau cylinder, sewage enters the tank through the inlet valve.

It rises above the filtering waterline through the buffer box clapboard.

The purified water enters into the bottom of the tube through the grid mesh slot and flows out.

With this procedure, the grid mesh also has been cleaned at the same time.

And during this time, the impurities and organic matters whose size is greater than the slot of the grid mesh is blocked and transferred into the other side of the grid mesh.

Finally, the blocked impurities and organic matters are discharged by the unloader into the slag hopper.

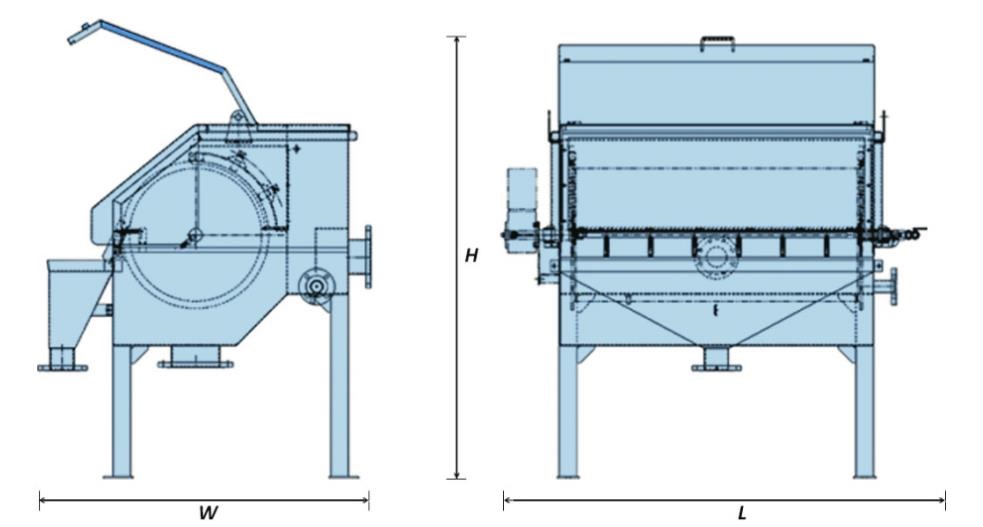

Externally rotary fed drum screen model

| Industry Type | Slot (mm) | RDS03/300 | RDS06/400 | RDS06/700 | RDS06/1000 | RDS06/1300 | RDS06/1600 | RDS08/2000 | RDS08/2500 |

|---|---|---|---|---|---|---|---|---|---|

| Paper Industry | 0.5 | 6 | 20 | 40 | 60 | 80 | 100 | 130 | 190 |

| Slaughter House | 0.5 | 4 | 15 | 30 | 45 | 60 | 75 | 95 | 130 |

| Seafood Industry | 0.75 | 5 | 17 | 35 | 50 | 70 | 90 | 110 | 140 |

| Meat Industry | 0.75 | 6 | 20.5 | 40 | 60 | 80 | 100 | 130 | 190 |

| Meat Industry | 1.0 | 7.5 | 25 | 50 | 75 | 100 | 125 | 150 | 220 |

| Vegetable Industry | 1.0 | 12 | 40 | 75 | 110 | 150 | 180 | 220 | 330 |

Externally rotary fed drum screen advantage

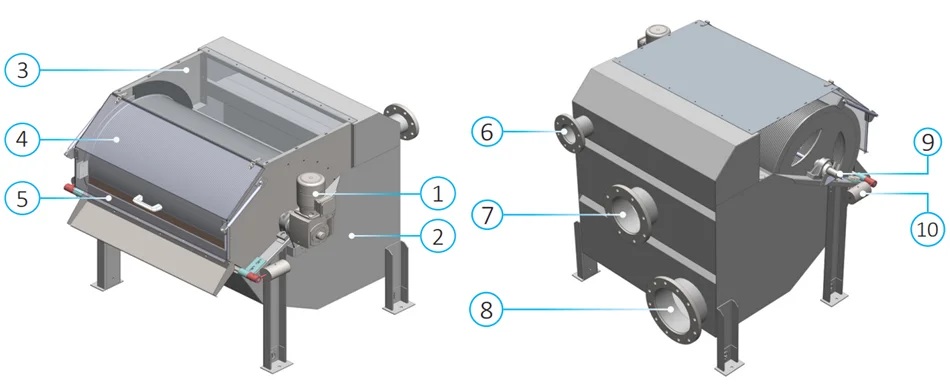

1. Material: stainless steel, corrosion resistance, compact structure, and easy installation;

2. With the inverted trapezoidal section, the grid makes the slag not easy to jams mesh filters;

3. Adopted control motor, the externally fed rotary drum filter can maintain the best working condition according to the water flow;

4. Special flusher device can brush away a small amount of impurity on the surface of the grid mesh;

5. Compact structure, the smallest amount of space when the same amount of processing;

6. The drum surface is made of a molded grid and has excellent hydraulic characteristics.

Externally rotary fed drum screen feature

1. All 304 stainless steel construction.

2. Headbox with overflow protection.

3. Solid unitary frame.

4. Wedge wire drum.

5. Doctor blade assembly with Monel blade.

6. Internal spray bar.

Externally rotary fed drum screen application

Typical applications: separation of various solids and sludges from municipal and industrial wastewater, food processes, pulp and paper production and rendering processes;

removal of extruded pellets from cooling baths; and separation of debris from any variety of plant and equipment-cleaning processes.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China