Externally rotary fed drum screen description

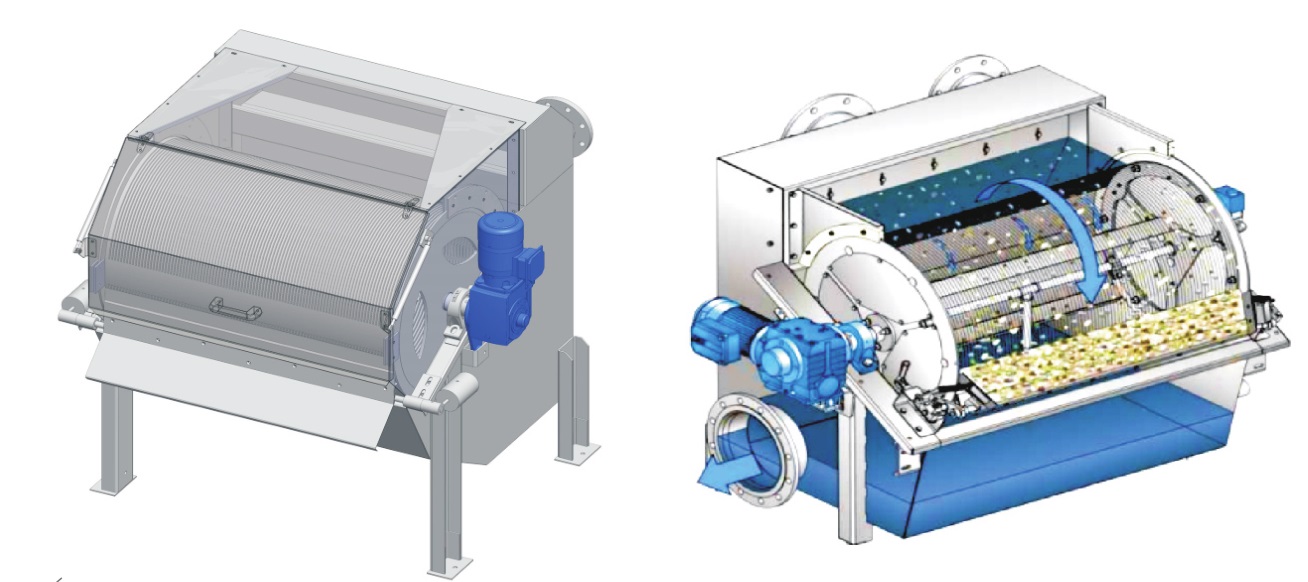

The externally fed rotary drum screen is a reliable self-cleaning wedge wire screen that performs fine micro-screening for municipal wastewater treatment.

This screening technology performs particularly well in applications with wastewater containing high levels of oil or grease and in scum applications that may obscure other types of screens. It is used for fine screening of primary sewage influent at the head of the canal and for screening of clarifier flotsam.

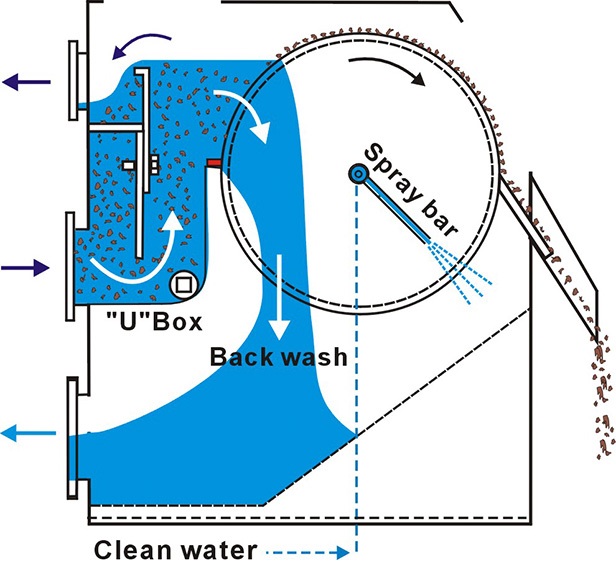

The flow of suspended liquid for sieving is oriented with the surface of the rotating screen perpendicular to the holes between the rods.

As the filtered liquid passes through the holes of the screen and discharges into the tank below the cylinder, the solids are trapped on the surface of the same screen and are attracted by rolling friction to the spillway vanes, which transfer them to a special container.

The rods of the cylinder are wedge-shaped, allowing an uninterrupted flow of hydraulic pressure and minimizing the risk of solids sticking and causing blockages.

Externally rotary fed drum screen function

Separation of Solids from Liquid: The primary function of externally fed rotary drum screens is to separate solid particles from a liquid stream.

This is particularly important in wastewater treatment plants where the goal is to remove solid contaminants from sewage or industrial wastewater before it can be discharged or further treated.

Screening and Filtration: As the liquid flows into the drum screen, the solid particles and debris are captured on the surface of the rotating drum due to the perforations or slots.

The size of these openings can be customized based on the specific requirements of the application. Larger openings allow larger particles to pass through, while smaller openings capture finer solids.

Continuous Operation: One of the advantages of externally fed rotary drum screens is that they can operate continuously. The rotation of the drum ensures a continuous screening process, making them suitable for applications where a constant flow of liquid needs to be processed.

Self-Cleaning Mechanism: To prevent clogging and maintain efficient operation, many rotary drum screens are equipped with a self-cleaning mechanism. This mechanism typically involves brushes or spray nozzles that clean the drum’s surface as it rotates, dislodging and removing accumulated solids.

Efficient Solids Removal: Rotary drum screens are known for their efficiency in removing solids from liquid streams. They are often used as a preliminary treatment step in wastewater treatment plants to protect downstream processes and equipment from damage or contamination.

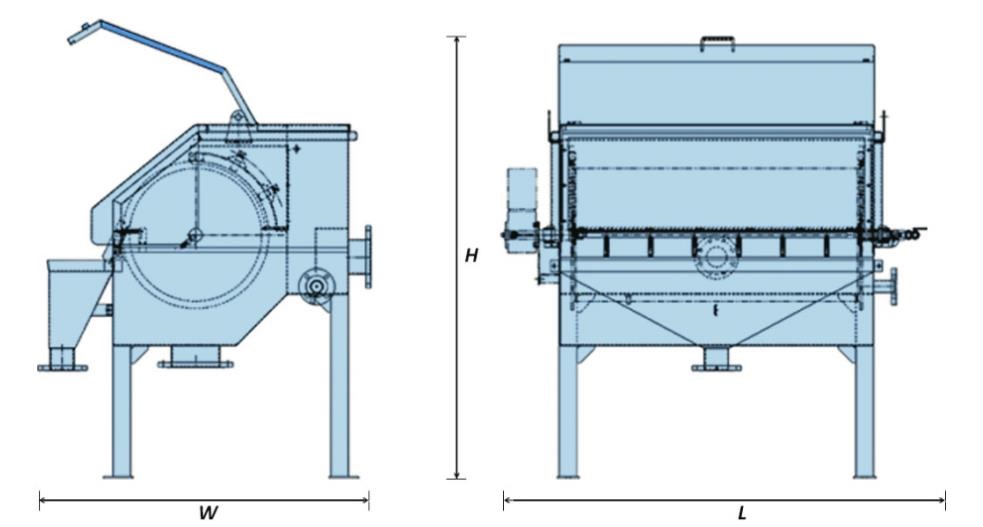

Variability in Design: Externally fed rotary drum screens come in various designs, including different drum configurations, materials, and sizes. The choice of design depends on factors such as the type of solids being removed, the flow rate of the liquid, and the specific requirements of the application.

Overall, externally fed rotary drum screens play a crucial role in the treatment and purification of liquid streams by effectively separating solid contaminants, improving water quality, and protecting downstream processes and equipment.

Externally rotary fed drum screen model

| Industry Type | Slot (mm) | RDS03/300 | RDS06/400 | RDS06/700 | RDS06/1000 | RDS06/1300 | RDS06/1600 | RDS08/2000 | RDS08/2500 |

|---|---|---|---|---|---|---|---|---|---|

| Paper Industry | 0.5 | 6 | 20 | 40 | 60 | 80 | 100 | 130 | 190 |

| Slaughter House | 0.5 | 4 | 15 | 30 | 45 | 60 | 75 | 95 | 130 |

| Seafood Industry | 0.75 | 5 | 17 | 35 | 50 | 70 | 90 | 110 | 140 |

| Meat Industry | 0.75 | 6 | 20.5 | 40 | 60 | 80 | 100 | 130 | 190 |

| Meat Industry | 1.0 | 7.5 | 25 | 50 | 75 | 100 | 125 | 150 | 220 |

| Vegetable Industry | 1.0 | 12 | 40 | 75 | 110 | 150 | 180 | 220 | 330 |

Externally rotary fed drum screen advantage

1. Most efficient screening technology.

2. Sieve/drum separating part of the fats / oils.

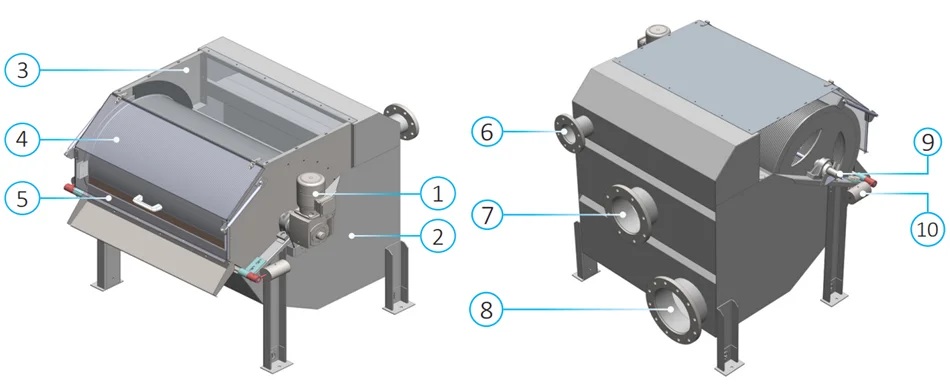

3. Structure & Drum in stainless steel 304 or 316L.

Externally rotary fed drum screen feature

1. Screen cylinder of heliical–wound wedge wire.

2. Screen slot openings 0.005” to 0.250” for a variety of applications.

3. Screen assembly complete with internal support(s), tie rods, end rings, hub and shafts.

4. Influent headbox designs to handle pumped or gravity flow feed, complete with flow dampening weir(s).

5. Influent overflow bypass piping.

6. Chassis designs for open or enclosed filtrate discharge.

7. Internal CIP manifold assembly with sprays designed for high pressure cleaning.

8. Solids discharge blade assembly of UHMW construction.

9. Shaft mounted, variable speed drives.

10. All metal components of stainless steel construction.

Externally rotary fed drum screen application

Industrial WWT (incl. Sludge Treatment)

Abattoirs (Slaughterhouses)

Beverage Industry Waste Water

Food Processing & Catering Waste Water

Fruit & Vegetable Processing Waste Water

Pulp & Paper Processing, Starch & By-products Processing

Tanneries, Dyeing Works

Plastics Recycling Industry Waste Water

Livestock Breeding (Manure Treatment)

Municipal Waste Water Treatment (incl. Sludge Treatment)

Clean Water Treatment

Industrial Solid Waste Handling & Treatment / Animal By-products Handling & Processing

Incinerators

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China