Product description

Industrial Filtration Housings

Also known as filter vessels, housings encase filter bags and cartridges. DAGYEE heavy-duty housings are available in various sizes, materials of construction and custom features for high-level filtration. An ideal choice for stand-alone, manifold or duplex filter systems.

Product function

Inflow: The unfiltered liquid enters the common inlet chamber of the housing.

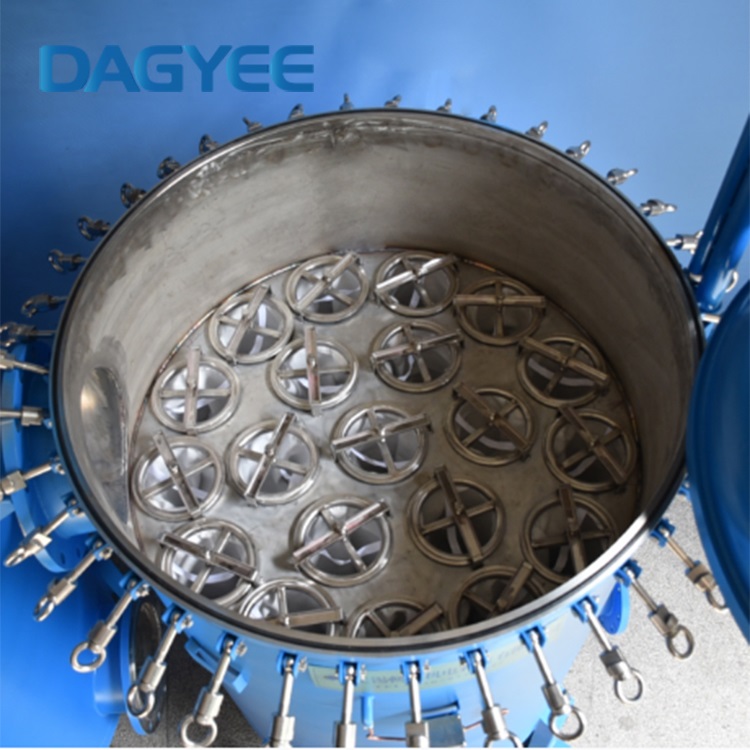

Parallel Distribution: The flow is evenly distributed across all the filter cartridges housed within the vessel.

Simultaneous Filtration: The fluid passes from the outside to the inside of each cartridge simultaneously. Contaminants are trapped on the exterior surface or within the depth of the cartridge media.

Consolidated Outflow: The purified fluid from each cartridge converges into a common outlet chamber before exiting the housing.

High Capacity: This parallel design allows the system to handle large volumes of fluid while capturing a significant amount of contaminants before maintenance is required.

Product technical

Seal type: O-rings and flat gasket

Sealing material: nitrile rubber(chemitum), silicone, fluorine rubber, usually use silicon

Rubber seal Filter interface: the threaded, clamp(hoop), GB, HG, DIN, ANSI

Filtration accuracy: 1μm - 100 μm

Body material: SS304/SS 316

Single filter Cartridges housings

| Model | Max. Flow Rate (m³/h) | Max. Operating Conditions (bar/°C) | Filter specifications | Inlet/Outlet | Height mm | Max. Cartridge Diameter mm |

|---|---|---|---|---|---|---|

| DYG-1-10" | 0.5 M³/H | 6/120 | Ø65*250 | 1/2" | 380 | Ø89 |

| DYG-1-20" | 1 M³/H | 6/120 | Ø65*500 | 3/4" | 630 | Ø89 |

| DYG-1-30" | 1.5 M³/H | 6/120 | Ø65*750 | 1" | 880 | Ø89 |

| DYG-1-40" | 2 M³/H | 6/120 | Ø65*1000 | 1" | 1130 | Ø89 |

Single microporous filter housings

| Model | Max. Flow Rate (m³/h) | Max. Operating Conditions (bar/°C) | Filter specifications | Inlet/Outlet-Quick Connector | Height mm | Max. Cartridge Outside Diameter |

|---|---|---|---|---|---|---|

| DYG-C1-10" | 0.5 M³/H | 6/120 | Ø68*250 | 1 1/4" | 608 | Ø102 |

| DYG-C1-20" | 1 M³/H | 6/120 | Ø68*500 | 1 1/4" | 850 | Ø102 |

| DYG-C1-30" | 1.5 M³/H | 6/120 | Ø68*750 | 1 1/4" | 1100 | Ø102 |

| DYG-C1-40" | 2 M³/H | 6/120 | Ø68*1000 | 1 1/4" | 1350 | Ø102 |

5 Cartridges filter Housings

| Model | Max. Flow Rate (m³/h) | Max. Operating Conditions (bar/°C) | Filter specifications | Inlet/Outlet | Height mm | Max. Cartridge Outside Diameter |

|---|---|---|---|---|---|---|

| DYG-5-10" | 2.5 M³/H | 6/150 | Ø65*250 | 3/4" | 550 | Ø219 |

| DYG-5-20" | 5 M³/H | 6/150 | Ø65*500 | 1" | 850 | Ø219 |

| DYG-5-30" | 7.5 M³/H | 6/150 | Ø65*750 | 1 1/2" | 1100 | Ø219 |

| DYG-5-40" | 10 M³/H | 6/150 | Ø65*1000 | 2" | 1390 | Ø219 |

5 Cartridges filter Housings with flange

| Model | Max. Flow Rate (m³/h) | Max. Operating Conditions | Filter specifications | Inlet/Outlet | Height mm | Max. Cartridge Outside Diameter |

|---|---|---|---|---|---|---|

| DYG-5F-10' | 2.5 M³/H | 0-1.0MPa | Ø65*250 | 3/4" | 550 | Ø219 |

| DYG-5F-20' | 5 M³/H | 0-1.0MPa | Ø65*500 | 1" | 850 | Ø219 |

| DYG-5F-30' | 7.5 M³/H | 0-1.0MPa | Ø65*750 | 1 1/2" | 1100 | Ø219 |

| DYG-5F-40' | 10 M³/H | 0-1.0MPa | Ø65*1000 | 2" | 1390 | Ø219 |

Single bag filter housings

| Model | Max. Flow Rate (m³/h) | Max. Operating Conditions (bar/°C) | Filter specifications | Inlet/Outlet | Height mm | Max. Cartridge Outside Diameter |

|---|---|---|---|---|---|---|

| DYG-1-1S | 18 M³/H | 12/150 | Ø180*410 | 1 1/2" flange | 1040 | Ø219 |

| DYG-1-2S | 36 M³/H | 12/150 | Ø180*810 | 2" flange | 1300 | Ø219 |

| DYG-1-4S | 10 M³/H | 12/150 | Ø105*380 | 1 1/2" BSP female | 850 | Ø133 |

| DYG-1K-1S | 18 M³/H | 12/150 | Ø180*410 | 1 1/2"flange | 1010 | Ø219 |

Multi Bag Filter Housings

| Model | Max. Flow Rate (m³/h) | Max. Operating Conditions (bar/°C) | Filter specifications | Inlet/Outlet | Height mm | Max. Cartridge Outside Diameter |

|---|---|---|---|---|---|---|

| DYG-2D-2S | 70 M³/H | 12/150 | Ø180*810 | 2" | 1600 | Ø420 |

| DYG-3D-2S | 100 M³/H | 12/150 | Ø180*810 | 3" | 1800 | Ø506 |

| DYG-4D-2S | 130 M³/H | 12/150 | Ø180*810 | 4" | 1800 | Ø506 |

| DYG-6D-2S | 200 M³/H | 12/150 | Ø180*810 | 4" | 2100 | Ø650 |

| DYG-8D-2S | 250 M³/H | 12/150 | Ø180*810 | 5" | 2100 | Ø710 |

| DYG-12D-2S | 400 M³/H | 12/150 | Ø180*810 | 6" | 2100 | Ø910 |

High-Efficiency Processing, Ensures Production: Capable of handling high-flow conditions that single-cartridge housings cannot meet, directly supporting main production lines and boosting overall capacity.

Extended Service Cycles, Reduces Costs: The high dirt-holding capacity significantly extends intervals between cartridge changes, reducing consumable costs and maintenance labor expenses.

System Redundancy, Ensures Operational Reliability: Even if one or several cartridges become clogged or damaged, the remaining cartridges continue to operate, providing a buffer for scheduled maintenance and effectively preventing unplanned downtime.

High-Capacity Design: Constructed to hold several to dozens of cartridges, significantly increasing the total filtration surface area and dirt-holding capacity.

Robust Construction: Typically made from carbon steel with protective coatings or stainless steel (SUS304/316L) for strength and corrosion resistance in demanding environments.

Efficient Flow Distribution: Internal baffling or design features ensure even flow across all cartridges, preventing premature clogging of any single cartridge.

Product application

Chemicals

Electronics

Food and Beverage

Industrial

Oil and Gas

Power and Utilities

Water

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China