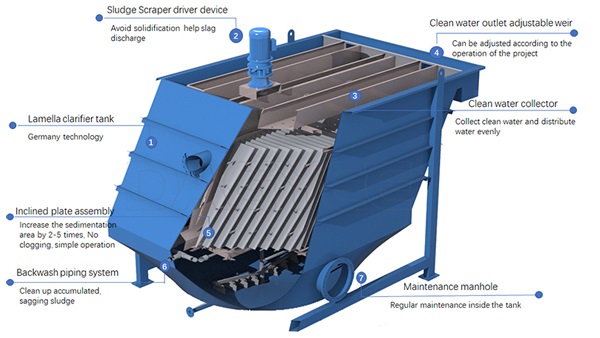

The DAGYEE Lamella Clarifier is designed to provide low cost, efficient solids removal from a wide range of waste and process liquids. The inclined plate design allows the total gravity settling area to be as much as ten times more than the actual floor space occupied by the clarifier. Integral chemical mixing and flocculation tanks are available, as well as options for enhanced sludge thickening.

The Flash Mix and Flocculation Tanks (optional) allow for the addition of chemicals and polymers that will aid the settling process — adjusting pH to precipitate dissolved solids and/or enhancing the agglomeration of suspended particles into heavier, more settle-able floc. The liquid is fed from these tanks into the clarifier through the inlet chamber, which directs flow into the separation section.

The liquid then enters the lower area of the laminar plates through side slots which distribute it across the entire width of the plates. Particulate settles onto the face of the plates and slides down to the clarifier bottom. The clarified liquid exits the plate sections through weirs at the top of the unit which are designed to develop and control adequate pressure drop, maintaining laminar flow through the plates. The clarified liquid then flows into the effluent chamber and out of the clarifier.

Lamella clarifier available options

• Flash mixing/flocculation tank with agitator

• Full glass steel or stainless steel structure

• Concrete tank design

• Special coatings and plates

• Integrated mechanical sludge thickener

• Overhaul platforms and ladders

• In-house laboratory analysis to optimize equipment

• Drinking water design

• Gasket and removable cover

• Automatic desilting

• Instrumentation and control

• Chemical feed equipment

• Sludge treatment and dewatering

• Pilot size units for field testing

Lamella clarifier model

DLC-I Gravity Lamella ,V shape mud bucket, simple structure, no energy consumption.

DLC-II Lamella with scraper,Increase the mechanical transmission mechanism, the mud discharge is better and smoother, and it matches the unit with large processing capacity.

DLC-III Super hydraulic Lamella,Reduced footprint, efficient sedimentation, detachable transportation.

| DLC Model | Capacities (m³/h) | Piping Connections (mm) | Physical Dimensions (m) | |||||

|---|---|---|---|---|---|---|---|---|

| Inlet(a) | Effluent(b) | Sludge(c) | Backwash(d) | L | W | H | ||

| DLC 5 | 5 | 80 | 80 | 50 | 50 | 2.55 | 1.6 | 2.9 |

| DLC 10 | 10 | 100 | 100 | 50 | 50 | 3.35 | 1.82 | 3 |

| DLC 15 | 15 | 100 | 100 | 50 | 50 | 3.35 | 2.02 | 3 |

| DLC 20 | 20 | 100 | 100 | 50 | 50 | 3.35 | 2.02 | 3 |

| DLC 30 | 30 | 150 | 150 | 50 | 50 | 4.2 | 2.22 | 3 |

| DLC 40 | 40 | 150 | 150 | 50 | 50 | 4 | 2.8 | 3 |

| DLC 50 | 50 | 200 | 200 | 50 | 50 | 4.65 | 2.82 | 3 |

| DLC 60 | 60 | 200 | 200 | 50 | 50 | 4.7 | 3 | 3 |

| DLC 70 | 70 | 250 | 200 | 50 | 50 | 6.4 | 2.6 | 3 |

| DLC 80 | 80 | 250 | 200 | 50 | 50 | 6.8 | 2.82 | 3 |

| DLC 100 | 100 | 250 | 250 | 50 | 50 | 7.05 | 3.02 | 3 |

Construction Materials

A wide range of construction materials and coatings are available to meet specific needs: Mild steel, Stainless steel, FRP, Plastics — PVC, Polypropylene, and many others.

DAGYEE Plate Cleaning Wand: Powerful Preventative Maintenance Tool

DAGYEE has developed a very effective tool for removing solids and debris accumulated on the separator plates of lamella-style inclined plate clarifiers: This product has been developed as part of our continued effort to improve operations and maintenance for your plant, and is the perfect compliment to all of our Plate Clarifiers.

The product is ideal for in-place cleaning of separator plates and is intended for use while the unit is in operation – greatly reducing downtime required during routine maintenance procedure.

Monroe Inclined Plate Vertical Clarifiers are carefully engineered to meet the specific requirements of each application. Well proven design criteria assure maximum performance of each clarifier. The design provides for easy field installation, fast start-up, and low maintenance costs.

While many installations provide adequate solids removal without influent pre-treatment, optional mixers and flocculator tanks are available to enhance efficiency when required. Some solids must be flocculated to achieve adequate mass to be effectively removed. Monroe Parallel Plate Vertical Clarifiers are manufactured in two different plate inclinations; the 45° clarifiers are designed for removal of heavy solids while the 55° clarifiers are designed for light solid removal applications.

Lamella clarifier application

Contact Us for a Consultation

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China