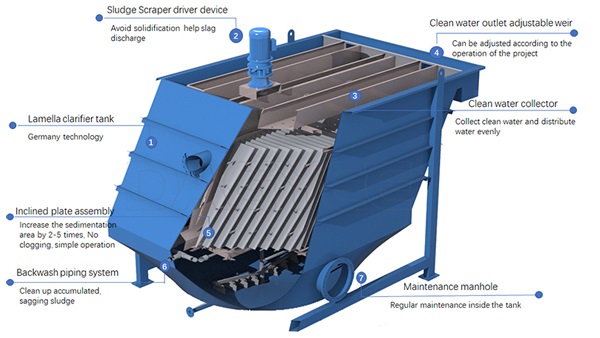

Lamella clarifier also called inclined plate sediment tank. It is good at high efficient combined type settling tank; set many dense inclined tube packing in sediment area, to make the suspended impurity in water sediment, water rise flow along inclined tube, the separated sludge down to the tank bottom along the inclined tube by gravity, then discharge it in concentration. Such tank can improve sediment efficiency 60~70%, it can improve treatment capacity 3~5 times in the same area. It can design different flow rate inclined plate sediment device according to raw waste water test report, it need dose flocculant usually.

The Lamella clarifier works when a solid/liquid stream that has been flocculated, enters a tank, and flows upward between a pack of inclined plates. The solids fall to the plate surface, where they slide by gravity down to a sludge collection hopper. The clarified effluent flows through orifice holes and exits the top of the settler. The sedimentation process in a Lamella clarifier involves the settling of suspended solids as the wastewater flows through inclined plates. These inclined plates, typically positioned at a 45 to 60-degree angle, increase the effective settling area within a compact footprint. Gravity drives the settling; as particles descend, the plates guide them to be collected at the bottom, making the removal process more efficient compared to conventional clarifiers.

Lamella clarifier available options

• Flash mixing/flocculation tank with agitator

• Full glass steel or stainless steel structure

• Concrete tank design

• Special coatings and plates

• Integrated mechanical sludge thickener

• Overhaul platforms and ladders

• In-house laboratory analysis to optimize equipment

• Drinking water design

• Gasket and removable cover

• Automatic desilting

• Instrumentation and control

• Chemical feed equipment

• Sludge treatment and dewatering

• Pilot size units for field testing

Lamella clarifier model

DLC-I Gravity Lamella ,V shape mud bucket, simple structure, no energy consumption.

DLC-II Lamella with scraper,Increase the mechanical transmission mechanism, the mud discharge is better and smoother, and it matches the unit with large processing capacity.

DLC-III Super hydraulic Lamella,Reduced footprint, efficient sedimentation, detachable transportation.

| DLC Model | Capacities (m³/h) | Piping Connections (mm) | Physical Dimensions (m) | |||||

|---|---|---|---|---|---|---|---|---|

| Inlet(a) | Effluent(b) | Sludge(c) | Backwash(d) | L | W | H | ||

| DLC 5 | 5 | 80 | 80 | 50 | 50 | 2.55 | 1.6 | 2.9 |

| DLC 10 | 10 | 100 | 100 | 50 | 50 | 3.35 | 1.82 | 3 |

| DLC 15 | 15 | 100 | 100 | 50 | 50 | 3.35 | 2.02 | 3 |

| DLC 20 | 20 | 100 | 100 | 50 | 50 | 3.35 | 2.02 | 3 |

| DLC 30 | 30 | 150 | 150 | 50 | 50 | 4.2 | 2.22 | 3 |

| DLC 40 | 40 | 150 | 150 | 50 | 50 | 4 | 2.8 | 3 |

| DLC 50 | 50 | 200 | 200 | 50 | 50 | 4.65 | 2.82 | 3 |

| DLC 60 | 60 | 200 | 200 | 50 | 50 | 4.7 | 3 | 3 |

| DLC 70 | 70 | 250 | 200 | 50 | 50 | 6.4 | 2.6 | 3 |

| DLC 80 | 80 | 250 | 200 | 50 | 50 | 6.8 | 2.82 | 3 |

| DLC 100 | 100 | 250 | 250 | 50 | 50 | 7.05 | 3.02 | 3 |

10 times the equivalent settling area of traditional clarifiers saves space and allows for efficient use of land

Patent-approved Lamella Clarifier design allows up to a 25% increase in capacity over the standard design

Self-cleaning plates and no moving parts require minimal maintenance and operator attention

Completely submerged plates maximize use of available plate area

Plates installed at 55⁰ optimize max solids settling efficiency

Standard corrosion-resistant FRP plates increase life expectancy

Plates available in several FRP grades can be used for high/low pH, high temperatures, and other extreme conditions

Plates available in various stainless steel grades allows for custom applications to be tackled

Rapid Mixing and Flocculation packages allow chemical use for improved overflow quality

Low power requirements for all drives and motors reduce operating cost

Optional FRP or rubber lined steel tank construction provides additional protection for highly corrosive applications

Optional NSF-61 materials of construction available for potable water applications

Optional rake mechanisms improve thickening and underflow quality

Lamella clarifier application

Contact Us for a Consultation

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China