Static screen wastewater description

Static Screen also known as arc screen, slit screen, inclined screen, inclined grille, hydraulic grille, curved grille.

It is mainly used for pre-dehydration, dewatering, de-intermediation operations, material or fiber classification and recovery of liquids.

It is a kind of non-power grille decontamination machine, which can be applied to the separation of solid SS and liquid of various waste water properties.

Using the gravity of the water flow itself to work, no energy consumption; a single machine handles a large amount of water, is not easy to block, and is easy to clean.

The whole machine is made of stainless steel, with high mechanical strength, no deformation and long service life.

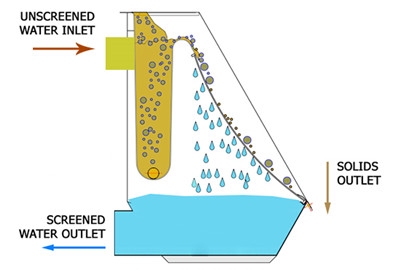

Static screen wastewater works

The main body of the Static Screen is a stainless steel arc or plane filter screen surface scientifically made of wedge wire steel rods.

The wastewater to be treated is evenly distributed on the Static Screen surface through the overflow weir.

The drainage is smooth and not easy to block; the solid matter is retained, the filtered water flows out from the gap of the sieve plate, and at the same time, under the action of

hydraulic force, the solid matter is pushed to the lower end of the sieve plate for discharge, so as to achieve the purpose of solid-liquid separation.

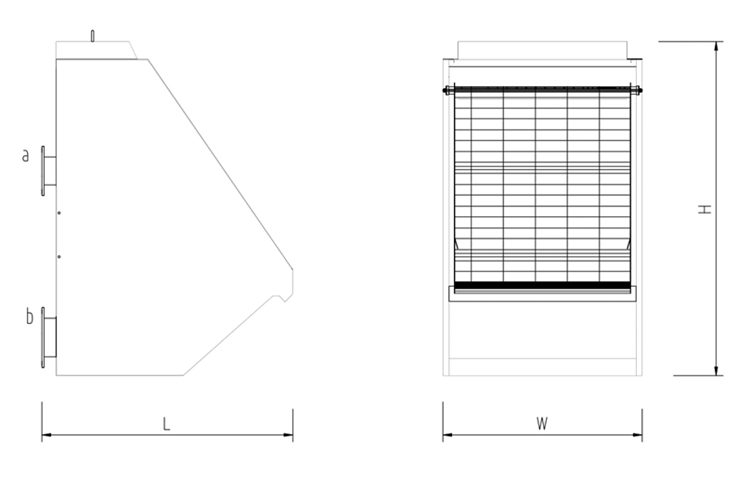

Static screen wastewater model

| HS Model |

Piping Connections Inlet(a) | Effluent(b) |

Physical Dimensions(m) L | W | H |

Weight (Kg) |

Capacities(m³/h) 0.5mm | 1mm | 1.5mm |

|---|---|---|---|---|

| HS-300 | 80 | 80 | 1.43 | 0.43 | 2 | 150 | 6 | 13 | 16 |

| HS-500 | 100 | 100 | 1.43 | 0.63 | 2 | 180 | 10 | 22 | 35 |

| HS-700 | 100 | 100 | 1.43 | 0.83 | 2 | 200 | 15 | 30 | 50 |

| HS-800 | 100 | 125 | 1.43 | 0.93 | 2 | 250 | 16 | 35 | 55 |

| HS-1000 | 150 | 150 | 1.43 | 1.13 | 2 | 280 | 20 | 45 | 70 |

| HS-1500 | 150 | 150 | 1.43 | 1.63 | 2 | 300 | 30 | 65 | 100 |

| HS-2000 | 200 | 200 | 1.43 | 2.13 | 2 | 400 | 40 | 75 | 120 |

Static screen wastewater advantage

What are the advantages of static screens in wastewater treatment? One of the first benefits is that they’re cost-effective.

They do not require electricity, and the purchase and installation costs are not out of reach, especially when you consider that they help make the rest of the wastewater

treatment process a little easier to manage.

Static screens also require very little maintenance, so you won’t need to spend a lot of time training or hiring additional workers to keep the screens maintained.

They clean themselves with water spray or bar rakes that clear the screen’s bars as the system moves around with the water’s current.

Some are also self-reversing to clear any jams that may occur after a storm where large branches enter systems that combine wastewater and stormwater runoff.

Static screens do their job effectively.

The mesh screens capture a lot. They can remove small particles of solidified grease, corn skins that are harder for a body to digest, or bone particles from animals that get into a sewer and end up in wastewater.

With these items removed before the remaining wastewater treatment measures take place, it eases wear and tear on equipment and gets the treatment process started faster.

With a static screen, they don’t need ideal conditions in order to work correctly. It doesn’t matter if flow rates increase or decrease or if temperatures are colder or hotter than

usual.

Static screens will work effectively in any condition.

Because static screens come in a variety of sizes and formats, it’s easy to fit one into your existing system.

Some require very little headroom.

When you’re shopping for the best static screen, finding a variety of sizes ends up helping out if you have little space.

Static screen wastewater feature

1. All stainless steel construction.

2. Strong and durable construction.

3. Low maintenance.

4. Quick and easy installation.

5. Zero energy consumption.

6. Special wire screen.

7. Screen washing system on option facilitating waste evacuation.

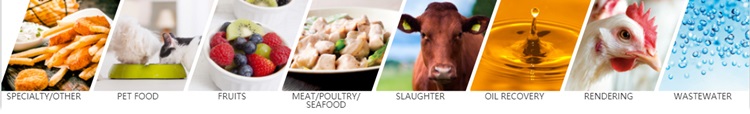

Static screen wastewater application

Urban waste water treatment plant

Textil industry

Creamery industry

Cannery industry

Laundry industry

Slaughterhouse waste water

Papermills

Food industries waste water treatment

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China