Static screen wastewater description

Parabolic Rundown Screens is a general term we use to cover Parabolic Screens, Rundown Screens, Bow Screens and Vibrating, Static Screens.

The non-mechanical, low maintenance aspects of the Parabolic Rundown Screen relies on a uniform feed over a fabricated distribution weir and a reversible wedge wire sieve

bend with a cross-flow presentation to allow effective dewatering and gravity solids discharge.

Standard radii at varying widths are available to suit flow rate and slot gap requirements.

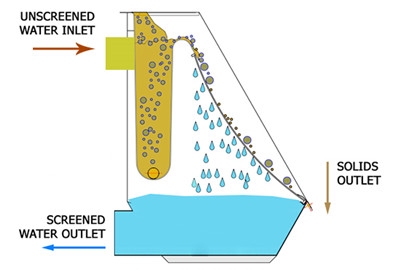

Static screen wastewater works

The fluid to be treated enters in a containment tank through a connection pipe placed in the rear side and it overflows on the front bow screen.

Flowing on the filtering screen, modeled with a specific radius, the clean water drains through the screen openings while the screened material pushed by its own weight and

water flow slides towards the screen.

This particular system offers a considerable hydraulic capacity compared to dimensions.

The filter screen is available with a wedge wire screen from 0.25mm to 3.0mm or with perforated sheet metal.

The screen can be realized in AISI 304 L stainless steel or AISI 316 L.

It can also be equipped with various options including cover closing and washing bars that can also be controlled by a solenoid valve.

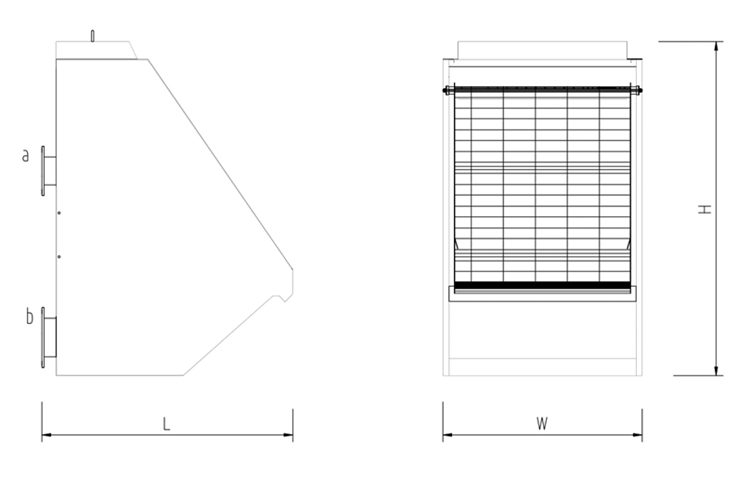

Static screen wastewater model

| HS Model |

Piping Connections Inlet(a) | Effluent(b) |

Physical Dimensions(m) L | W | H |

Weight (Kg) |

Capacities(m³/h) 0.5mm | 1mm | 1.5mm |

|---|---|---|---|---|

| HS-300 | 80 | 80 | 1.43 | 0.43 | 2 | 150 | 6 | 13 | 16 |

| HS-500 | 100 | 100 | 1.43 | 0.63 | 2 | 180 | 10 | 22 | 35 |

| HS-700 | 100 | 100 | 1.43 | 0.83 | 2 | 200 | 15 | 30 | 50 |

| HS-800 | 100 | 125 | 1.43 | 0.93 | 2 | 250 | 16 | 35 | 55 |

| HS-1000 | 150 | 150 | 1.43 | 1.13 | 2 | 280 | 20 | 45 | 70 |

| HS-1500 | 150 | 150 | 1.43 | 1.63 | 2 | 300 | 30 | 65 | 100 |

| HS-2000 | 200 | 200 | 1.43 | 2.13 | 2 | 400 | 40 | 75 | 120 |

Static screen wastewater advantage

1. Corrosive free and robust product construction.

2. Assembly built to withstand harsh operational conditions and ozone and chemical attacks, ensuring long-lasting operation.

3. Combination of a front and back cleaned screen in a single unit (Optional).

4. Adjustable Optimized Rinsing System with means of both Water Level Difference and Timer to conserve water (Optional).

5. Low cost for maintenance and operation.

6. Designed with the ability to provide tailor-made solutions that match each project-specific need.

7. Eco-friendly solution with recycled material and low CO2 footprint.

Static screen wastewater feature

1. Robust Construction: Made from premium-grade stainless steel, ensuring long-lasting durability and resistance to corrosion.

2. High Filtration Efficiency: Engineered to effectively separate solids from liquids, providing high filtration efficiency and reducing operational downtime.

3. Easy Installation and Maintenance: User-friendly design allows for quick installation and easy maintenance, minimizing the need for technical expertise.

4. Versatile Applications: Suitable for a wide range of industries, including chemical processing, mining, pharmaceuticals, and textiles.

5. Customizable Options: Available in various sizes and configurations to meet your specific filtration needs.

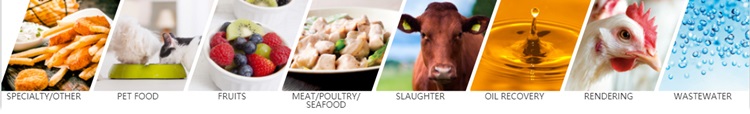

Static screen wastewater application

Mining

Textiles

Sugar Mills Poultry or fish

Meat Processing Pulp and Paper Mills

Food Processing Animal Waste Processing

Fruit and Vegetable Processing Industrial Solids Separation or Recovery

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China