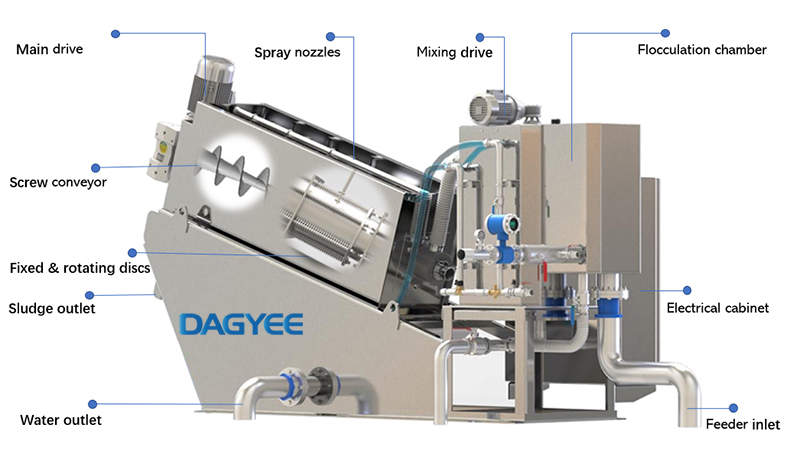

Sludge dehydrator descriptions

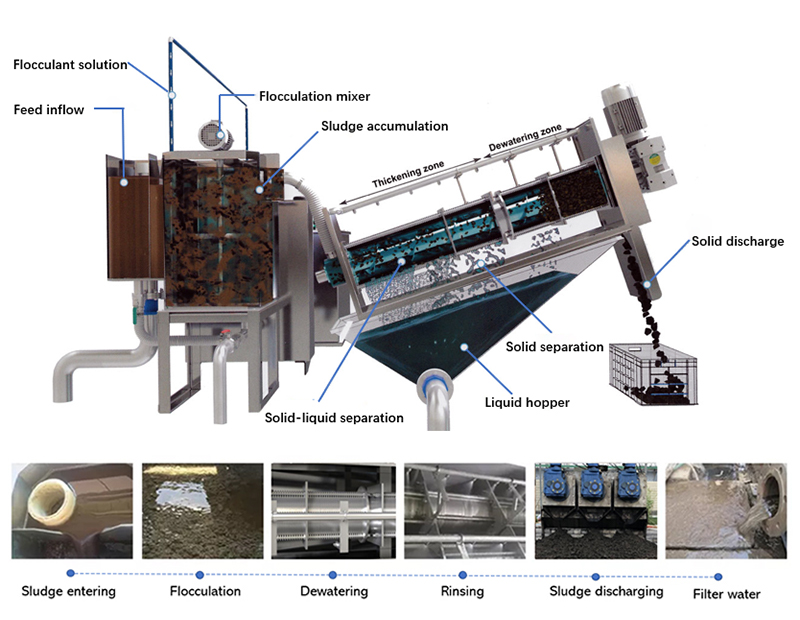

The rotation of the screw shaft produces a great internal pressure under the blocking action of the backpressure plate while pushing the sludge transportation so that the volume is continuously reduced, and the purpose of dewatering is finally achieved.

Sludge dehydrator process

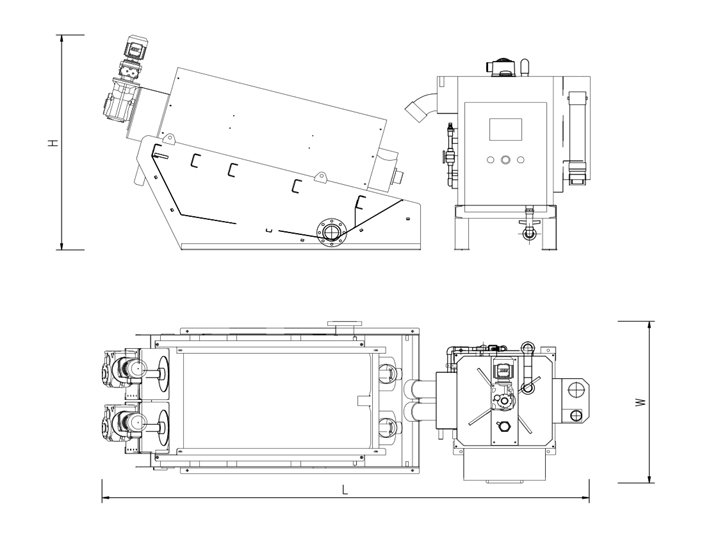

Sludge dehydrator model

| Model | DS capacity(g/h) | Sludge capacity (m³/h) | Sludge treatment capacity | Spiral diameter | Discharge Distance | Size(mm) | Net.Kg | Run Kg | Power | Washing Q | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min | Max | 2g/L | 5g/L | 2g/L | 5g/L | 10g/L | 20g/L | 25g/L | 50g/L | L | W | H | |||||||

| DL101 | 3 | 5 | 1.5 | 0.6 | 1.5 | 0.6 | 0.5 | 0.25 | 0.2 | 0.1 | Φ100×1 | 215 | 1816 | 756 | 1040 | 200 | 290 | 0.2 | 24 |

| DL131 | 6 | 10 | 3 | 1.2 | 3 | 1.2 | 1 | 0.8 | 0.4 | 0.2 | Φ130×1 | 260 | 1969 | 756 | 1040 | 220 | 315 | 0.36 | 24 |

| DL132 | 12 | 20 | 6 | 2.4 | 6 | 2.4 | 2 | 1 | 0.8 | 0.4 | Φ130×2 | 250 | 2069 | 910 | 1040 | 275 | 450 | 0.62 | 48 |

| DL202 | 18 | 30 | 9 | 3.6 | 9 | 3.6 | 3 | 1.5 | 1.2 | 0.6 | Φ200×2 | 350 | 2500 | 935 | 1270 | 470 | 730 | 1.11 | 64 |

| DL301 | 30 | 50 | 15 | 6 | 15 | 6 | 5 | 2.5 | 2 | 1 | Φ310×1 | 495 | 3255 | 905 | 1600 | 850 | 1320 | 0.74 | 40 |

| DL302 | 60 | 100 | 30 | 12 | 30 | 12 | 10 | 5 | 4 | 2 | Φ310×2 | 495 | 3455 | 1285 | 1600 | 1500 | 2230 | 1.11 | 80 |

| DL303 | 90 | 150 | 45 | 18 | 45 | 18 | 15 | 7.5 | 6 | 3 | Φ310×2 | 495 | 3055 | 1690 | 1600 | 1520 | 3080 | 1.86 | 120 |

| DL352 | 120 | 200 | 60 | 24 | 60 | 24 | 20 | 10 | 8 | 4 | Φ350×2 | 580 | 4240 | 1550 | 2190 | 1950 | 3400 | 3.75 | 144 |

| DL353 | 180 | 300 | 60 | 36 | 60 | 36 | 30 | 15 | 12 | 6 | Φ350×3 | 580 | 4460 | 2100 | 2160 | 2600 | 4850 | 6 | 216 |

| DL402 | 120 | 200 | 60 | 24 | 60 | 24 | 20 | 10 | 8 | 4 | Φ410×2 | 585 | 4140 | 1550 | 2250 | 2450 | 3400 | 3.75 | 144 |

| DL403 | 180 | 300 | 60 | 36 | 60 | 36 | 30 | 15 | 12 | 6 | Φ410×3 | 585 | 4420 | 2100 | 2250 | 3350 | 4850 | 6 | 216 |

Sludge dehydrator advantages

1. Waste Volume Reduction

2. Reduced Transportation Costs

3. Consistent Cake Dryness with Lower Risk of Spilling/Leaking

4. Wastewater Recycling

5. Equipment is Easily Automated

6. Eco-Friendly

Sludge dehydrator key features

The main body of the sludge dewatering machine can be divided into two parts: in the first part where gravity concentration occurs, the screw will rotate downward and push out a mixture of water and solid materials that are below it.

In the second part where there is no gravity concentration, but with pressure generated by the rotating screw, pressure is applied to keep the solid materials pressed between rings so that they can get dehydrated by moisture vaporization during operation.

Sludge dehydrator applications

Dying Plant

ETP (Primary & Secondary)

Slaughter House

Oil Refinery

Tannery Sludge

Sludge from DAF

Solid Fuel Boiler Scrubber Water

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China