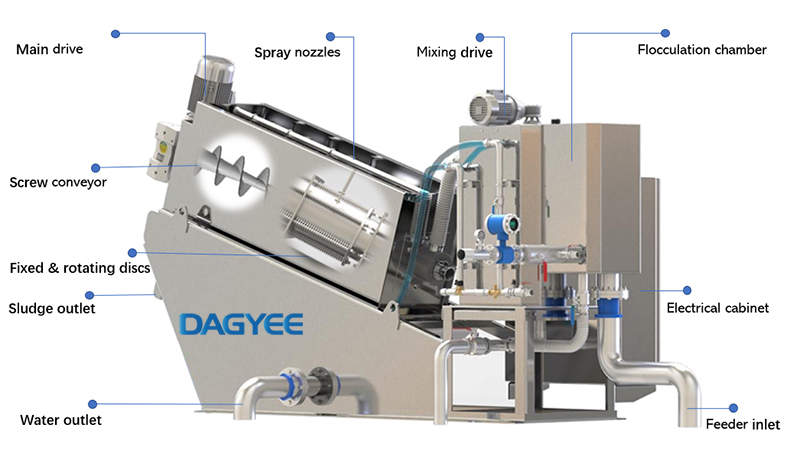

Sludge Dehydrator Description

In the process of wastewater treatment, water-content sludge of different nature is generated. The main purpose of sludge dewatering equipment is to reduce the water content of sludge and reduce the volume of sludge, thus facilitating the subsequent treatment or disposal of sludge. Its compact structure and low energy consumption are increasingly accepted by wastewater treatment contractors. Choosing a better quality and reasonably priced sludge dewatering machine will bring the user a good profit.

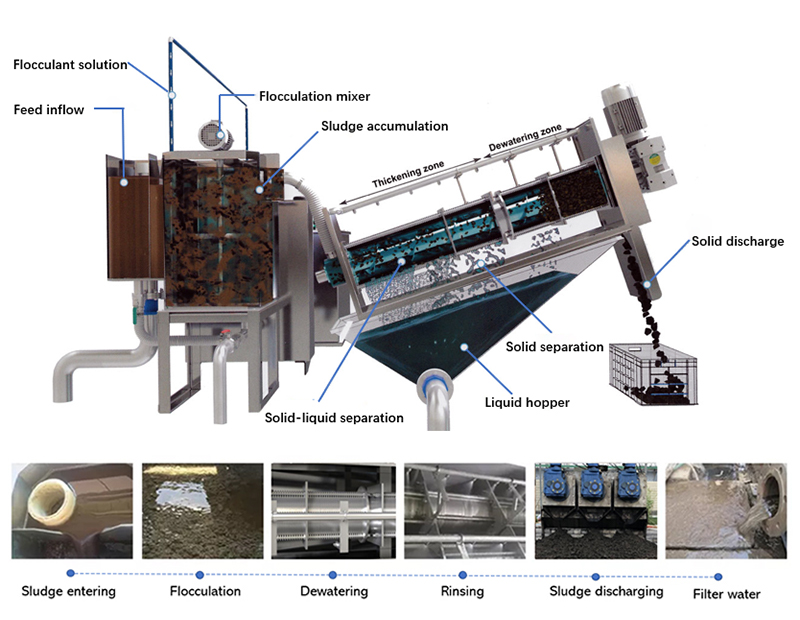

Sludge Dehydrator Process

Sludge dewatering is a process that separates water from sludge to reduce its volume and weight. This is a crucial step in wastewater treatment, as it reduces the cost of transportation, disposal, and further treatment. The dewatered sludge—often referred to as “cake”—is easier to handle, store, and dispose of, or can even be repurposed for use as compost, fuel, or in land application.

Sludge Dehydrator Model

Model

DL303

DS

capacity kg/h

90--150 kg/h

Sludge capacity m3/h(2-50g/L)

3-45

Spiral diameter mm

¢310*3

Discharge

Distance mm

495

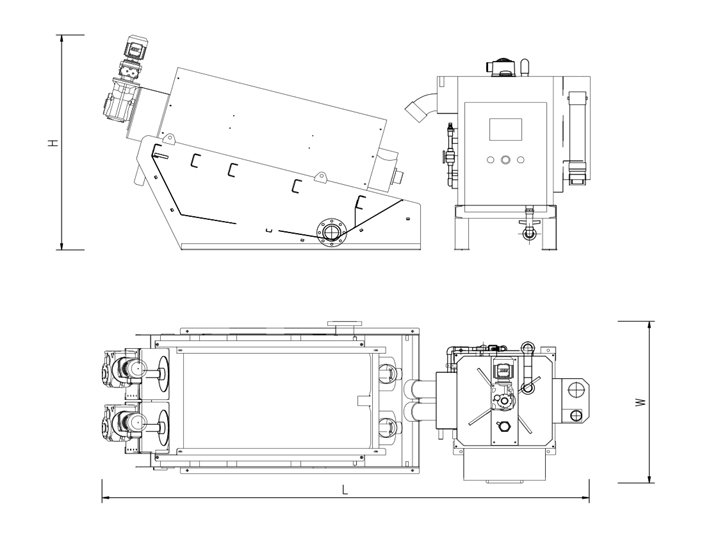

Size L*W*H

mm

3605*1690*1600

Net.Kg

1520

Run Kg

3080

Power

Kw

1.86

Washing Q L/h

120

Sludge Dehydrator Advantages

Power-saving operation

The screws inside the cylinder of the Sludge Dewatering Machine rotate at a very low speed – approximately 2 to 4 rpm – and consume very little energy. It reduces the power consumption in kWh per ton of dry solids by up to 90% in comparison with a centrifugal dewatering machine.

Water-saving design

The Sludge Dewatering Machine uses the moving rings to create a unique self-cleaning mechanism to keep the filter element clean and “open”, whereas competing technologies use large amounts of (pressurized) rinsing water for this purpose. That explains the major savings in rinsing water consumption that it offers.

Compared to a belt press and a centrifugal dewatering machine with the same throughput, a VOLUTE™ uses 90 to 95% less rinsing water.

Significantly extended lifespan of consumables reduces OPEX

The moving rings are driven by an external driveshaft to prevent contact with the screws, creating a friction-less design. This drastically extends the lifetime of consumable parts, resulting in an even better OPEX than our classic models already have.

No pre-thickening required

The machine’s design integrates both thickening and dewatering of the sludge, which allows processing of low-concentration sludges – having a TS of 0.5% or more – in a single machine without any pre-thickening system. This eliminates the costs for construction and operation of thickening and storage systems and reduces odors. On top, it reduces phosporus and nitrogen emmissions back into the waste water treatment plant, by dewatering the sludge when it’s as fresh as possible.

Sludge Dehydrator Application

The versatility of the Sludge Dewatering Machine allows it to handle a wide variety of sludge types. It is suitable for:

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China