Sludge Dehydrator Description

In the process of wastewater treatment, water-content sludge of different nature is generated. The main purpose of sludge dewatering equipment is to reduce the water content of sludge and reduce the volume of sludge, thus facilitating the subsequent treatment or disposal of sludge. Its compact structure and low energy consumption are increasingly accepted by wastewater treatment contractors. Choosing a better quality and reasonably priced sludge dewatering machine will bring the user a good profit.

Sludge Dehydrator Process

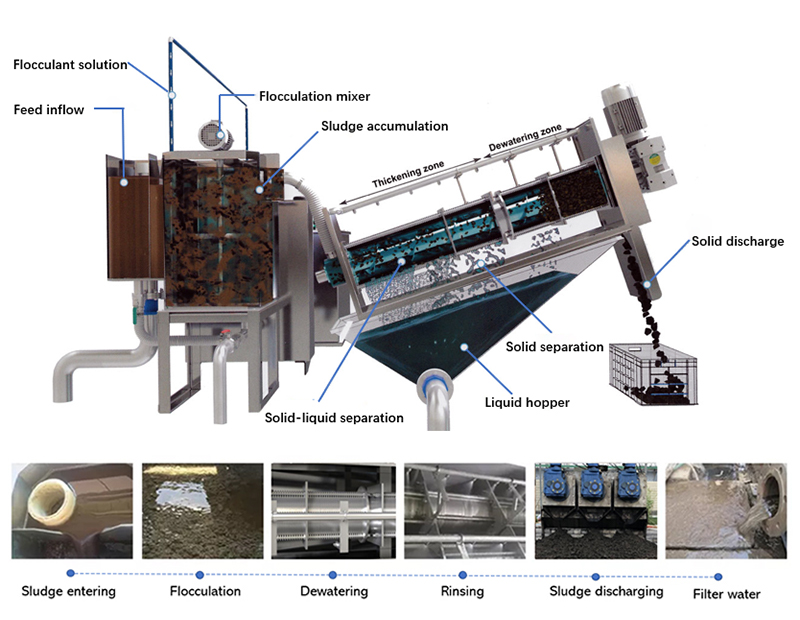

The operation of a Multi-disc Screw Press follows these basic steps:

Sludge Conditioning

Polymer is mixed with the incoming sludge to agglomerate the solid particles, forming larger flocs. This increases filtration efficiency.

Sludge Feeding

The conditioned sludge is fed into the dewatering drum.

Thickening and Dewatering

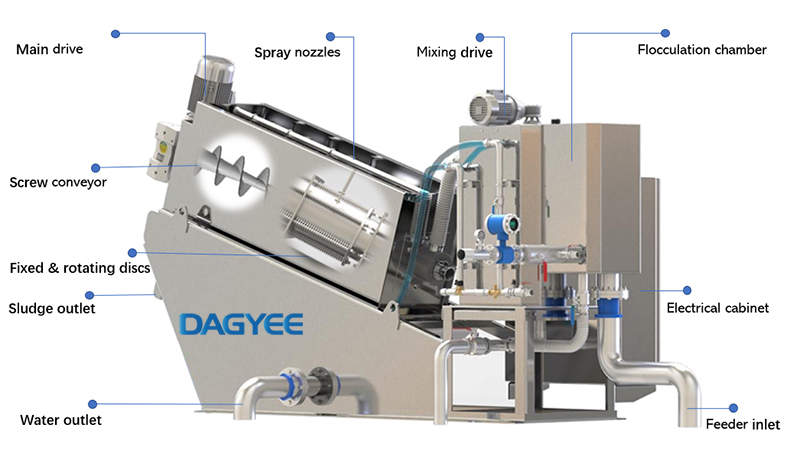

The drum consists of a screw shaft that rotates slowly. Surrounding this screw are alternating fixed and moving rings. As the screw rotates, it transports the sludge toward the outlet. During this movement:

Water is drained through the narrow gaps between the discs.

Pressure increases as the pitch of the screw tightens and the volume decreases, squeezing more water out of the sludge.

Cake Discharge

The dewatered sludge (now a semi-solid cake) is pushed out from the end of the screw shaft for disposal or reuse.

Sludge Dehydrator Model

Model

DL303

DS

capacity kg/h

90--150 kg/h

Sludge capacity m3/h(2-50g/L)

3-45

Spiral diameter mm

¢310*3

Discharge

Distance mm

495

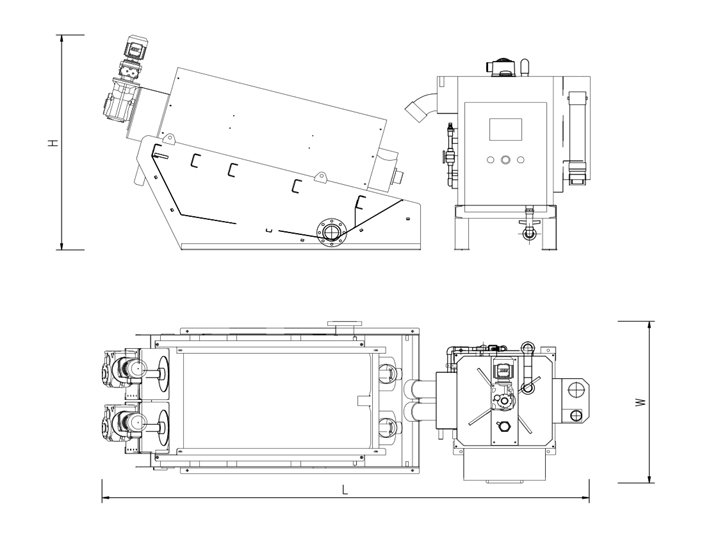

Size L*W*H

mm

3605*1690*1600

Net.Kg

1520

Run Kg

3080

Power

Kw

1.86

Washing Q L/h

120

Sludge Dehydrator Advantages

Sludge Dehydrator Features

This series of screw press machines are suitable for the pressing and dewatering of solid materials like sludge and other solids, such as some waste food materials and other industrial wastes. The main body of the sludge dewatering machine can be divided into two parts: in the first part where gravity concentration occurs, the screw will rotate downward and push out a mixture of water and solid materials that are below it. In the second part where there is no gravity concentration, but with pressure generated by the rotating screw, pressure is applied to keep the solid materials pressed between rings so that they can get dehydrated by moisture vaporization during operation.

Sludge Dehydrator Application

DAGYEE has pioneered the technique of manufacturing Sludge Dewatering Machine in China. These sludge dewatering press are intended for mechanical dewatering of community and industrial wastewater sludge. They are recommended for wastewater sludge dewatering on low-capacity municipal wastewater facilities, as well as for food, pulp-and-paper, pharma,textile, chemical, oil-refining and similar industries. These sludge dewatering press are efficiently used for dewatering rates of up to 1000 kg/hr – dry solid mass. These dehydrators are a good alternative to traditional dewatering equipment. It provides dewatered sludge with a moisture content of less than 80% in conditions of classic wastewater treatment plants.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China