Sludge Dehydrator Description

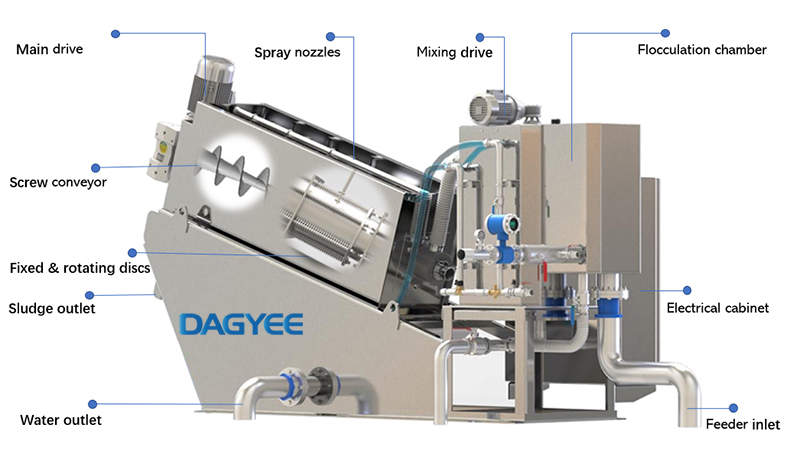

Screw press sludge dewatering machine is an efficient and reliable solution to sludge water management and wastewater treatment. It utilizes a screw mechanism to transport and compress sludge, separating the water from the solid materials. The dewatered sludge cake is with reduced moisture content and volume, making it easier to handle and dispose of. Dagyee is a trusted manufacturer of sludge dewatering screw press, providing customization options to meet specific demands. Our machine also serves wastewater treatment, food proccessing industry, etc.

Sludge Dehydrator Process

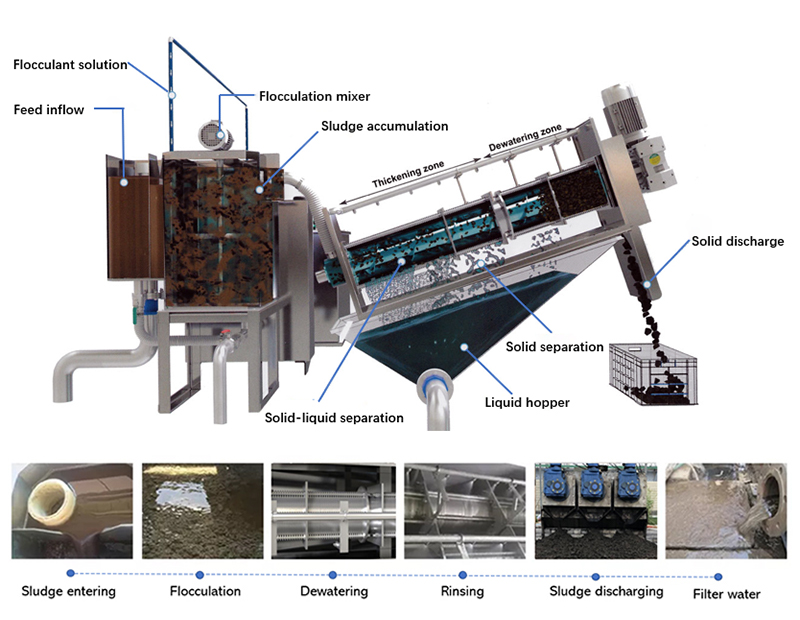

The dehydrator is mainly composed of sludge premix module, concentration and dewatering module and electric control system. In the actual working process, the sludge is pumped to the metering tank by an external conveying pump. The sludge after distillation further flows into the flocculation tank, reacts with the flocculant fully under the stirring of the agitator to produce stable alum, and then enters the dewatering screw through the upper part of the flocculation tank. In the dehydrated body, alum flowers concentrate in the concentrated section by gravity and advance to the dehydrated section at the same time. In the process of propulsion, with the filter clearance and pitch gradually reduced, and the back pressure plate blocking effect.

The main body of the screw press dehydrator is a filter device which is superimposed by a plurality of fixed rings and floating rings, and the screw shaft runs through it. The anterior segment is concentrated and the posterior segment is dehydrated. Sludge concentration and dewatering are done in one cylinder. During the spiral rotation, the floating ring and the fixed ring will form a dislocation movement, and the water will be discharged from the gap between the floating ring and the fixed ring. It replaces the traditional filter cloth filtering method with a unique and subtle filter pattern.

Following the principles of force and water in the same direction, thin layer dehydration, appropriate pressure, and prolonged dehydration path, the screw press solves the problems of easy blockage, inability to handle low-concentration sludge and oily sludge, high energy consumption, and complex operation. The dehydration goal of high efficiency and energy saving was achieved.

Sludge Dehydrator Model

Model

DL303

DS

capacity kg/h

90--150 kg/h

Sludge capacity m3/h(2-50g/L)

3-45

Spiral diameter mm

¢310*3

Discharge

Distance mm

495

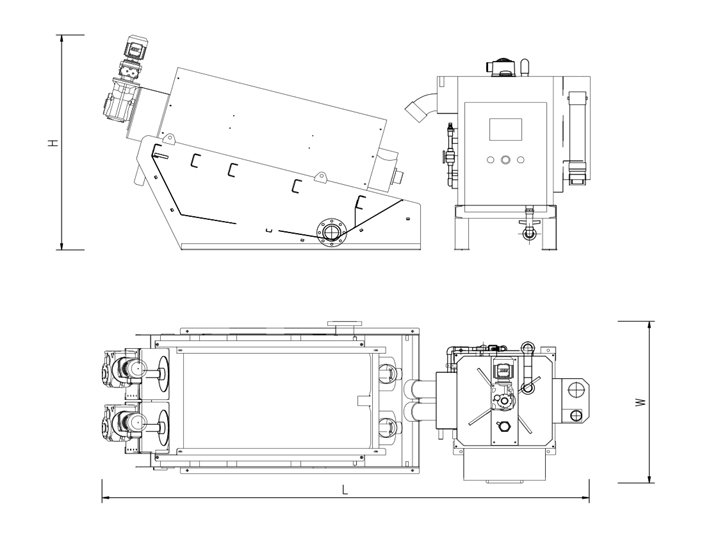

Size L*W*H

mm

3605*1690*1600

Net.Kg

1520

Run Kg

3080

Power

Kw

1.86

Washing Q L/h

120

Sludge Dehydrator Advantages

Sludge Dehydrator Features

Sludge Dehydrator Application

Screw press dewatering machine is widely used in fruit and vegetable juicing, agricultural waste dewatering, distiller’s grains dewatering, crushing and dewatering of fruit waste and vegetable waste, decomposition of food waste, extrusion dewatering of domestic waste, solid-liquid separation of animal feces, dewatering of pulp, sawdust, and sludge.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China