Sludge Dehydrator Description

Sludge dewatering is the process of separation of components of solid and liquid sludge to minimize the sludge disposal.

Sludge dewatering equipment is not intended to treat the sludge or liquid but; it only separates the liquid components & solid components so it will get easier & cost-effective to handle the separate phases of the disposal. Once the Final sludge has been dewatered, then the liquid is treated in ETP/STP & solid sludge is disposed.

The main purpose of the Sludge dewatering machine is to minimize handling and disposal. Sludge dewateringpress is the most cost-effective method of dewatering and hence helps to sustain the environmental objectives of the company.

Sludge Dehydrator Process

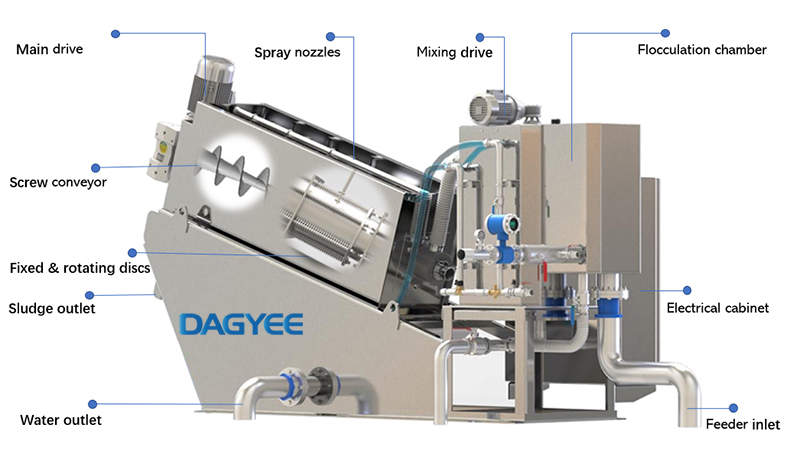

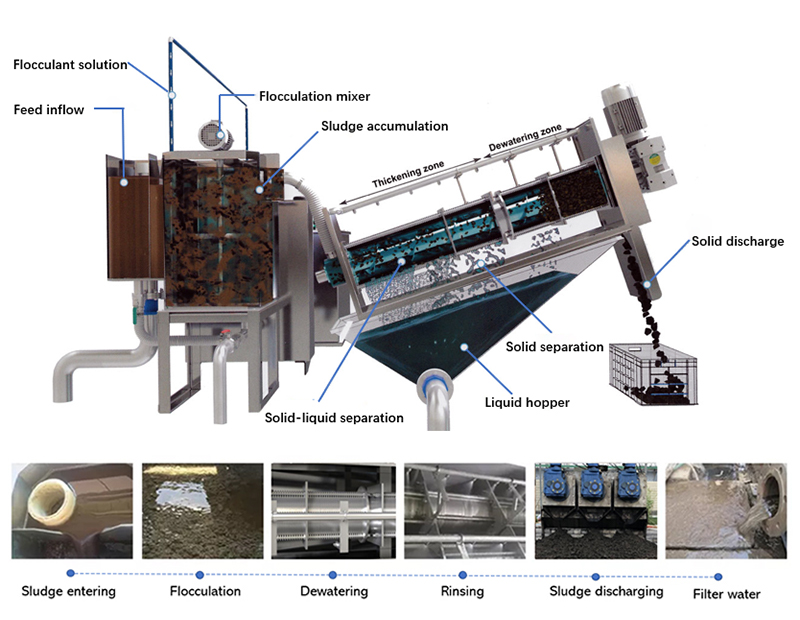

The screw press, with conical screw shaft and cylindrical screen, consists of three treatment zones: an inlet and drive zone, a three-part thickening and dewatering zone and a press zone with a pneumatic counterpressure cone. Cost-effective sludge dewatering with independent sludge treatment.

In the first part of the thickening and dewatering zone, the supernatant is quickly removed by a feed pump through a large free filter surface at low primary pressure. A pressure probe in the feed zone controls the primary pressure, thus ensuring consistent filtrate quality.

In the second part of the screen, the volume of material between the screw threads is reduced by means of a conical screw and the sludge is pressed against the inner surface of the screen, thus dewatering the sludge and decreasing the cake thickness. The screen aperture in this screen section is much smaller.

In the third part of the screen, the remaining water is pressed out of the sludge with minimum cake thickness by a pneumatic counterpressure cone at the press-out. The dewatered sludge is pushed by a screw conveyor over the pressure cone into the discharge chamber. The residence time of the sludge in the screw press as well as the filtering time can be adjusted by adjusting the speed of the screw shaft to meet individual requirements.

Sludge Dehydrator Model

Model

DL303

DS

capacity kg/h

90--150 kg/h

Sludge capacity m3/h(2-50g/L)

3-45

Spiral diameter mm

¢310*3

Discharge

Distance mm

495

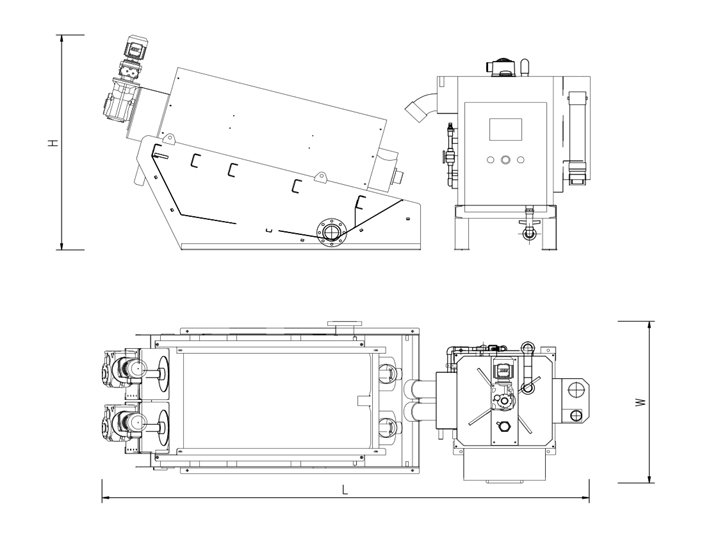

Size L*W*H

mm

3605*1690*1600

Net.Kg

1520

Run Kg

3080

Power

Kw

1.86

Washing Q L/h

120

Sludge Dehydrator Advantages

The power of up and down movement of the floating ring in the process of dehydration comes from the extrusion of the inner screw on the floating ring, so it is necessary to protect the edge of the spiral blade from wear. Whether the screw blade is protected by wear-resistant coating will affect the service life of the screw. Some manufacturers connect all the floating rings together with independent lead screws, and provide power with a power supply different from the main lead screw drive device to prevent the floating ring from contacting the spiral blade, so as to protect the lead screw and floating ring.

In the choice of motor, reducer and electrical components, manufacturers and users have different preferences for different brands and places of origin. Usually manufacturers will provide solutions according to their own standard configuration, but can also provide customized solutions according to user requirements.

The electric control cabinet centralized all the operation control of screw press dehydrator. According to the working site temperature, humidity, sunshine and other conditions, the user can choose carbon steel spray or stainless steel control cabinet. For more automated control, users can also ask manufacturers to design PLC control and display designs to detect health.

Sludge Dehydrator Features

Simple operation and maintenance — through a variety of induction control can realize all-weather automatic unattended operation, less routine maintenance items.

Compact design, saving space — screw dewatering water, flocculation mixing tank, electric control cabinet press adopts trinity design, easy installation, small footprint.

Energy saving, water saving, low noise, low vibration — the core component screw shaft speed is 2~4 RPM, so the power consumption is very low. Its self-cleaning structure can prevent the filter slit clogging, can save a lot of cleaning water. There is almost no noise and vibration when rotating at low speed, ensuring a comfortable and quiet working environment.

Strong anti-sludge ability, easy to separate and not blocked — self-cleaning structure of screw press dehydrator, not easy to cause filter seam blockage, even if the sludge can be easily handled. Kuosi also has an oil sludge treatment system to recover valuable substances from the sludge and reduce waste emissions. It should be noted that the sludge needs to be flocculated in the mixing tank and then passed through the overflow port into the dewatering water. Therefore, the sludge entering the screw press dehydrator must have certain fluidity.

Sludge Dehydrator Application

Dewatering screw press is widely used across various industries, with applications in fruit and vegetable juicing, plant dewatering, processing spent grains. It plays a vital role in managing agricultural waste, including grass, stalks, and coconut shells, as well as fruit and vegetable waste and food waste. Additionally, it effectively handles wastewater and slurry, excelling in managing animal manure. This versatile machine also dewaters materials like paper pulp and sludge, making it a key component in sustainable waste management practices.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China