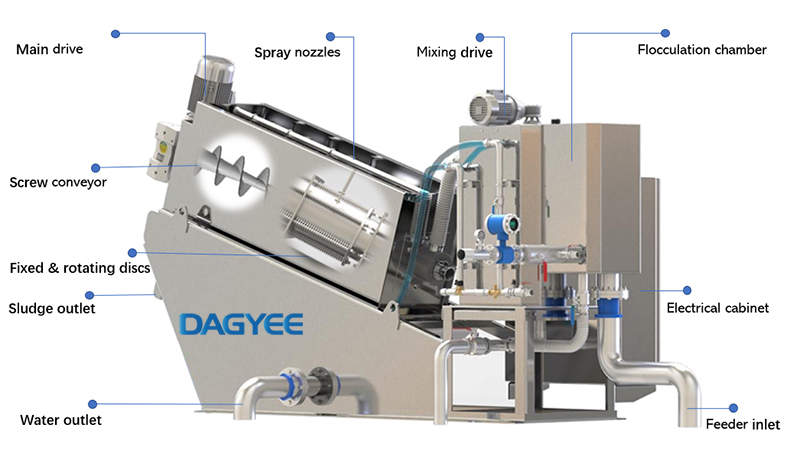

Sludge Dehydrator Description

Sludge produced in municipal and industrial wastewater treatment plants requires dewatering prior to further treatment or utilisation. In view of increasing sludge disposal costs it has become necessary to concentrate the sludge to a high solids content.

DAGYEE offers for this purpose commonly known systems for continuous sludge dewatering, e.g. belt filter presses and screw presses.

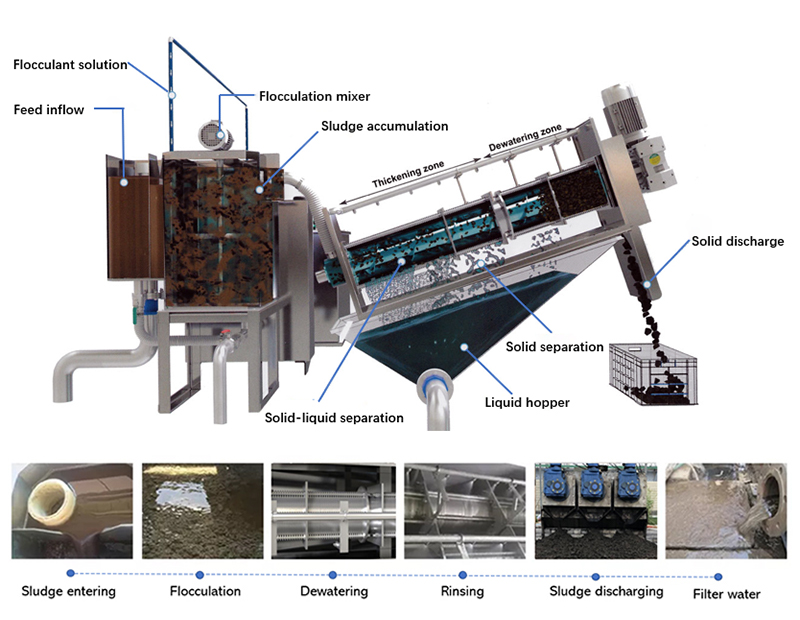

Sludge Dehydrator Process

Sludge dewatering is the process of separating solid and liquid sludge components to minimize sludge disposal. Often polymer flocculants are also added prior to sludge dewatering (using powder dosing system) to help the solid-liquid separation process.

Instead of treating sludge or liquids, the sludge dewatering facility will separate liquid and solid components, making it easier and cost effective to treat the different treatment stages. After final sludge dewatering, the liquid is treated in ETP/STP and the solid sludge is disposed of.

The main purpose of sludge dehydrators is to minimize treatment and disposal. Sludge dehydrators are the most cost-effective method of dehydration and therefore help to maintain the company’s environmental objectives.

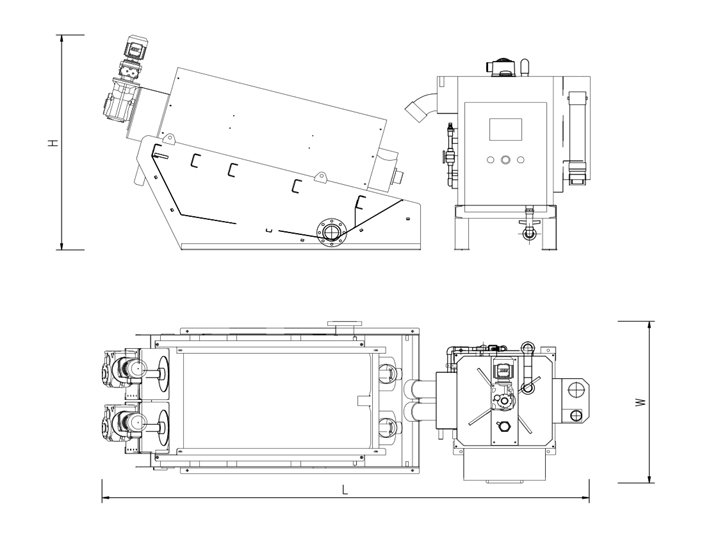

Sludge Dehydrator Model

Model

DL303

DS

capacity kg/h

90--150 kg/h

Sludge capacity m3/h(2-50g/L)

3-45

Spiral diameter mm

¢310*3

Discharge

Distance mm

495

Size L*W*H

mm

3605*1690*1600

Net.Kg

1520

Run Kg

3080

Power

Kw

1.86

Washing Q L/h

120

Sludge Dehydrator Advantages

Sludge Dehydrator Features

Optimize your wastewater sludge dewatering and sludge thickening

VecFlow™ technology delivers outstanding performance in wastewater sludge thickening and dewatering. The unique VecFlow™ feed zone of Aldec G3 decanters minimizes turbulence and reduces power consumption by up to 30% compared to traditional decanter centrifuges.

Minimal turbulence for maximum performance

Aldec G3 decanter centrifuges equipped with VecFlow™ technology for sludge thickening gives you maximum performance with minimal turbulence. Alfa Laval’s unique VecFlow™ sludge centrifuge feed zone reduces turbulence by more than 80% compared to traditional decanter centrifuges and cuts acceleration power by 40-50%.

Gentle acceleration

A traditional feed zone injects the sludge radially into the decanter bowl, continuously disturbing the internal flows and causing turbulence. A VecFlow™ feed zone, on the other hand, gives the feed a completely different flow path since it accelerates the sludge tangentially when entering the bowl of the decanter centrifuge.

Sludge centrifuges with better separation performance

Apart from reducing total power consumption in sludge thickening, the low turbulence also improves separation performance. The separation is more effective than in a traditional decanter centrifuges, with less break-up of flocs. Additionally, the efficient acceleration to full speed reduces wear on the conveyor.

Cut OPEX

Depending on your specific sludge-thickening requirements, you may wish to minimize polymer consumption, increase the dryness of the cake or boost capacity. The high separation performance in thickening and low power consumption leads to a low total cost of ownership and very short payback times. You often get a full return on your investment in less than one year.

Sludge Dehydrator Application

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China