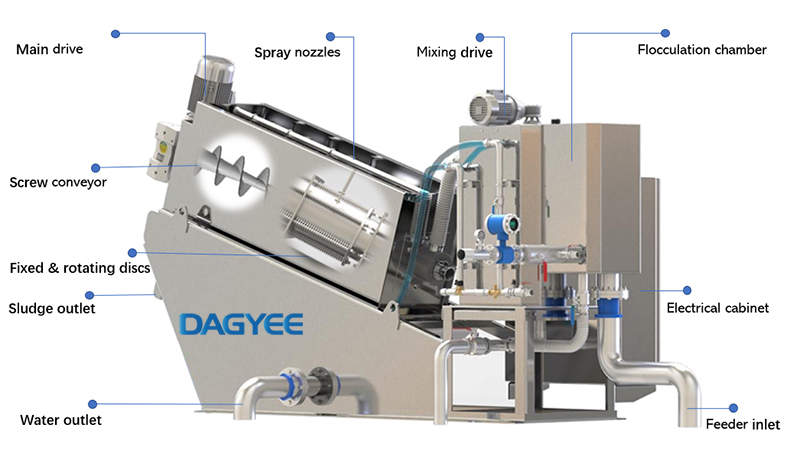

Sludge Dehydrator Description

Sludge produced in municipal and industrial wastewater treatment plants requires dewatering prior to further treatment or utilisation. In view of increasing sludge disposal costs it has become necessary to concentrate the sludge to a high solids content.

DAGYEE offers for this purpose commonly known systems for continuous sludge dewatering, e.g. belt filter presses and screw presses.

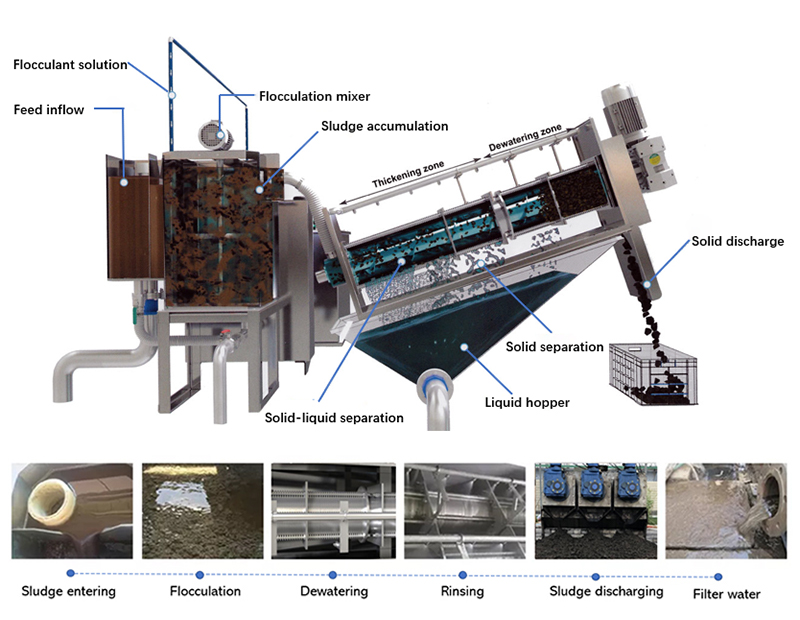

Sludge Dehydrator Process

Mechanical Preliminary Treatment

DAGYEE Solutions for mechanical wastewater pre.treatment: Contaminants and solids contained inwastewater are removed by screens and fine

screening systems as well as through sedimentationand separation processes.

Advanced Wastewater Treatment

The aim of advanced wastewater treatment is thereduction of one or more of the following pollu-tants: solids,COD, BOD, phosphorus, nitrate, mi-cropollutants and germs.

Elimination of Trace substances

DAGYEE offers solutions for the elimination of trasubstances and micropollutants from wastewatelwith qranulated activated carbon(GAC) and povdered activated carbon(PAC).

Sludge Treatment

DAGYEE offers highly efficient and comprehensivesolutions for sludge treatment, from mechanicalpre-treatment with screens to drying andincineration.

Screening in Pumping stations

Reliable screening and solids removal for pumpsand lifting units at combined and separate sewersystems. HUBER pumping station screens maintainthe operating stability of the pumps and protectthem against interfering substances.

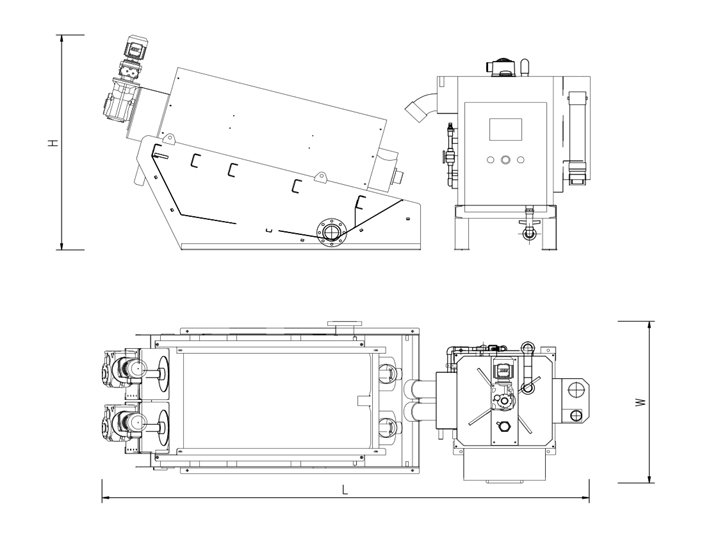

Sludge Dehydrator Model

Model

DL303

DS

capacity kg/h

90--150 kg/h

Sludge capacity m3/h(2-50g/L)

3-45

Spiral diameter mm

¢310*3

Discharge

Distance mm

495

Size L*W*H

mm

3605*1690*1600

Net.Kg

1520

Run Kg

3080

Power

Kw

1.86

Washing Q L/h

120

Sludge Dehydrator Advantages

Sludge Dehydrator Features

Experience the next level of performance with a groundbreaking sludge dewatering decanter

Sludge Dehydrator Application

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China