Sludge Dehydrator Description

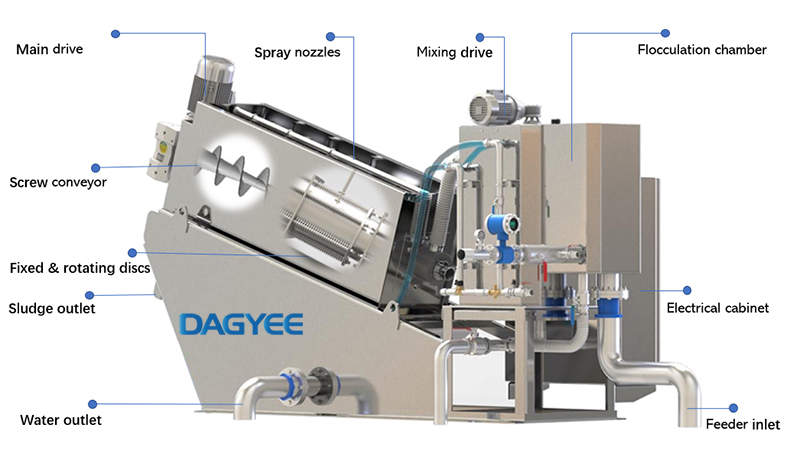

A screw press (SP) provides sludge dewatering by conveying the sludge along the inside of a permeable cylinder. It is based on a slowly-rotating (~5 RPM) Archimedean screw within a cylindrical screen (otherwise termed drum filter/screen or basket). It is normally inclined by ~20° to the horizontal to assist with the draining of water into the sump. The screen generally has an aperture rating below 0.5 mm and is based on wedge-wire or occasionally perforated metal.

Sludge Dehydrator Process

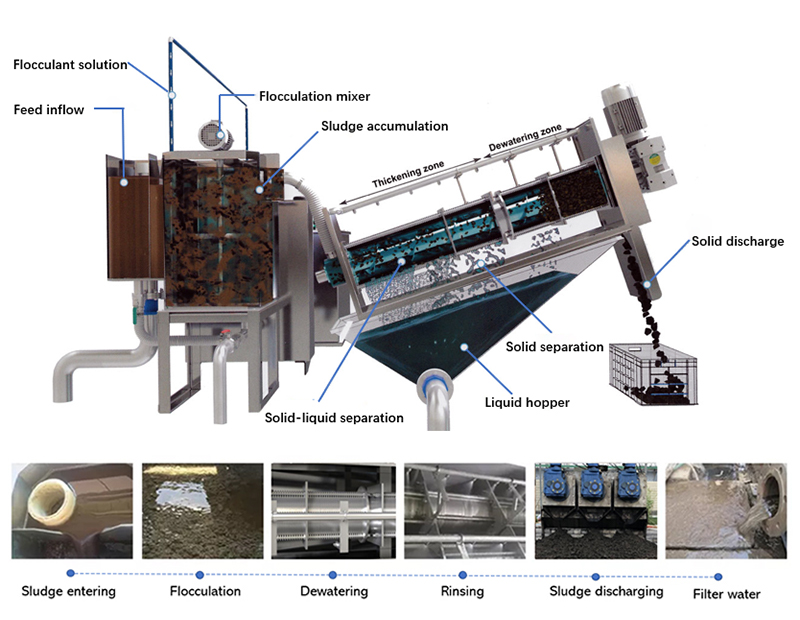

In contrast to manure dewatering manure, sludge dewatering needs to add flocculant to the sludge before pumping it into the dewatering machine. Then the sludge is transported by the rotating screw along a cylindrical screen at a slow rotating speed (1-4 RPM). As the sludge moves through the press, the pressure and compression is gradually increase, effectively extracting water from the sludge. The water flows out through the screen and is collected, while the solid sludge particles are retained. The solids continue to move along the screw, gradually compacting into drier sludge cake, which is discharged at the end of the screw press. The water content of the dewatered sludge cake is about 75%.

Sludge Dehydrator Model

Model

DL303

DS

capacity kg/h

90--150 kg/h

Sludge capacity m3/h(2-50g/L)

3-45

Spiral diameter mm

¢310*3

Discharge

Distance mm

495

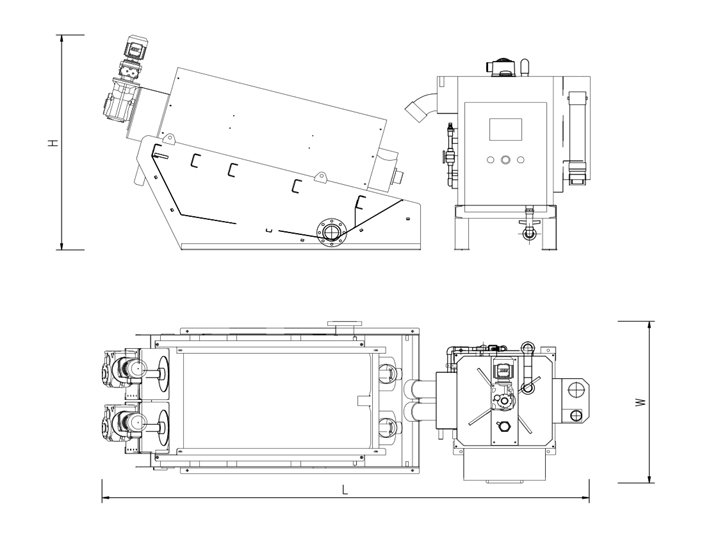

Size L*W*H

mm

3605*1690*1600

Net.Kg

1520

Run Kg

3080

Power

Kw

1.86

Washing Q L/h

120

Sludge Dehydrator Advantages

Patented Power Tubes for enhanced efficiency and reduced power consumption

.

SuperPond Design for optimal space utilization and improved separation performance.

Durable Wear-Resistant Materials used in critical components for extended lifespan and reliability.

Fully Open Feed Zone for superior separation and smooth operation.

360° Solids Discharge to prevent blockages and ensure continuous performance.

Baffle Disc Technology for higher capacity and drier cake solids.

Flexible Cone Configuration (Steep or Shallow) for effective separation of all types of slurry.

Customizable Conveyor Designs tailored for different slurry types.

Advanced Wear Protection Options for conveyor flights, catering to various processing requirements.

Sludge Dehydrator Features

PowerTubes

Liquid outlet with pond depth regulation and energy recovery

PowerTubes adjustable outlets are designed to release the liquid tangential to the rotating direction, supporting the bowl rotation and thereby recovering energy, and minimizing power consumption.

SuperPond

Increased separation performance and energy efficiency

Increasing the pond depth inside the bowl creates a larger volume, leading to longer retention time and improved separation performance. The SuperPond design features a deeper pond and smaller solids outlet diameter, resulting in high solids dryness and clean centrate at high flow rates, as well as low energy consumption.

VecFlow™

Rotating feed zone

Low turbulence in the decanter centrifuge bowl is essential for high separation performance and low power consumption. The VecFlow™ rotating feed zone gives you maximum performance with minimal turbulence.

FlightGuard

Robust wear protection for conveyor flights

FlightGuard wear protection consists of tiles welded to the conveyor of your decanter centrifuge, providing robust wear resistance and prolonged uptime in highly abrasive applications.

FeedProtect

Feed zone with replaceable wear protection

The uniquely designed FeedProtect feed zone ensures gentle product acceleration and minimal turbulence, resulting in low abrasion and power consumption. The FeedProtect design is equipped with replaceable wear-protection liners, ensuring high uptime of your decanter centrifuge.

Sludge Dehydrator Application

The machine can handle various types of sludge waters, including municipal, industrial sludge, biogas slurry, etc. It is also widely used in pulp and paper industry, food processing, mining and mineral processing, and more.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China