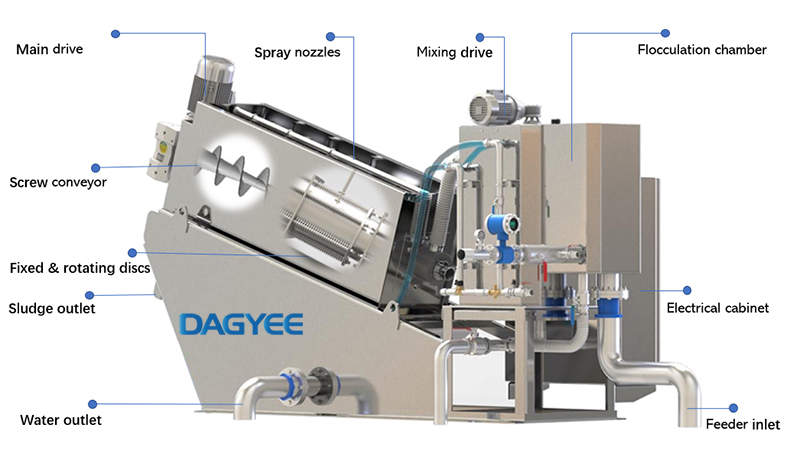

Sludge Dehydrator Description

DAGYEE machines for sludge dewatering: Reliable and efficient methods of sewage sludge dewatering by means of screw presses and belt filter presses.

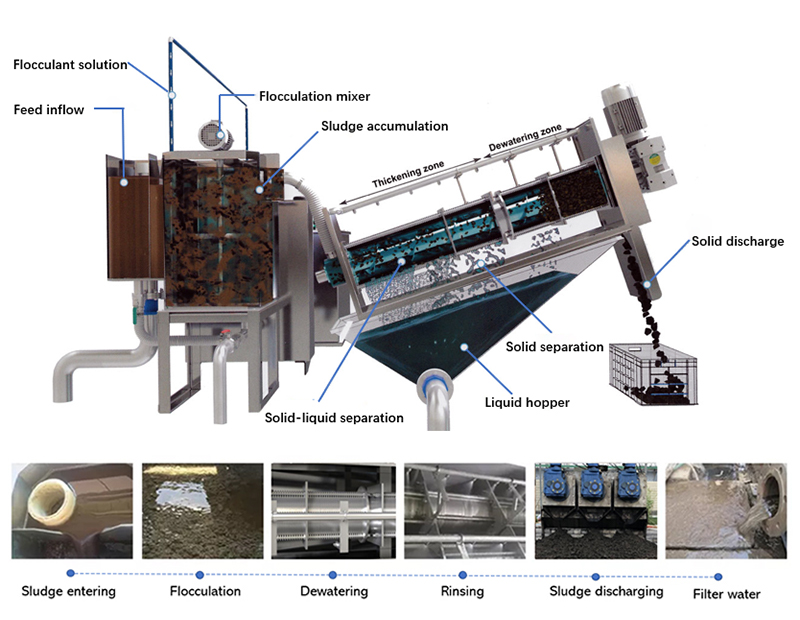

Sludge Dehydrator Process

A screw press (SP) provides sludge dewatering by conveying the sludge along the inside of a permeable cylinder. It is based on a slowly-rotating (~5 RPM) Archimedean screw within a cylindrical screen (otherwise termed drum filter/screen or basket). It is normally inclined by ~20° to the horizontal to assist with the draining of water into the sump. The screen generally has an aperture rating below 0.5 mm and is based on wedge-wire or occasionally perforated metal.

The screens are less susceptible to clogging than the filter media used for other thickening and dewatering processes. Consequently, spray-cleaning is applied only intermittently for around 2−4% of the operating time.

As with all thickening and dewatering processes, the product solids (or cake) content is dependent on the feedwater sludge quality. The cake solids content has been shown to be inversely proportional to the volatile solids (VS) of the feed sludge.

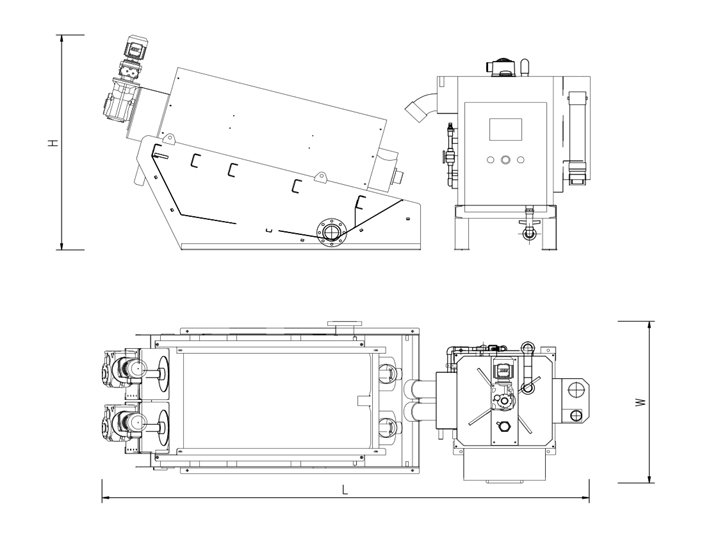

Sludge Dehydrator Model

Model

DL303

DS

capacity kg/h

90--150 kg/h

Sludge capacity m3/h(2-50g/L)

3-45

Spiral diameter mm

¢310*3

Discharge

Distance mm

495

Size L*W*H

mm

3605*1690*1600

Net.Kg

1520

Run Kg

3080

Power

Kw

1.86

Washing Q L/h

120

Sludge Dehydrator Advantages

Sludge Dehydrator Features

Sludge Dehydrator Application

We offer innovative and customized solutions to reliably meet your exact application and situation - for sparing and sustainable management of scarce resources, for recovery and recycling of energy and materials.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China