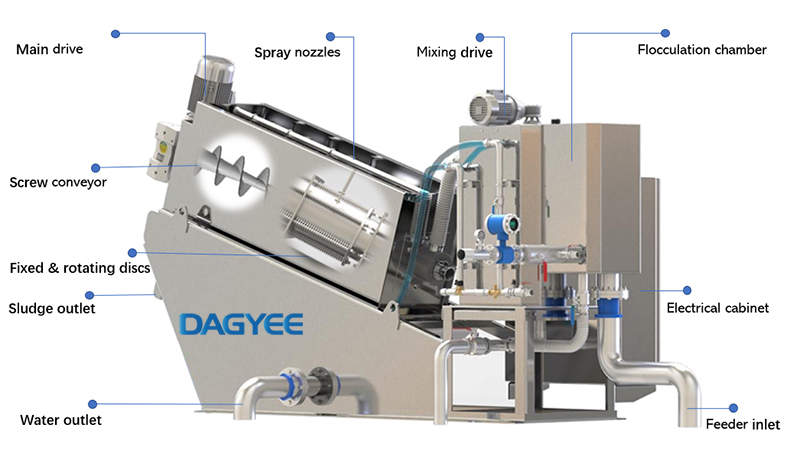

Sludge Dehydrator Description

The advanced range of sludge dewatering decanter centrifuges is ideal for making significant contributions to a sustainable environment. Its innovative design delivers peak performance at all times while reducing total power consumption by up to 40%. This improvement leads to substantial reductions in CO2 emissions during the sludge dewatering process.

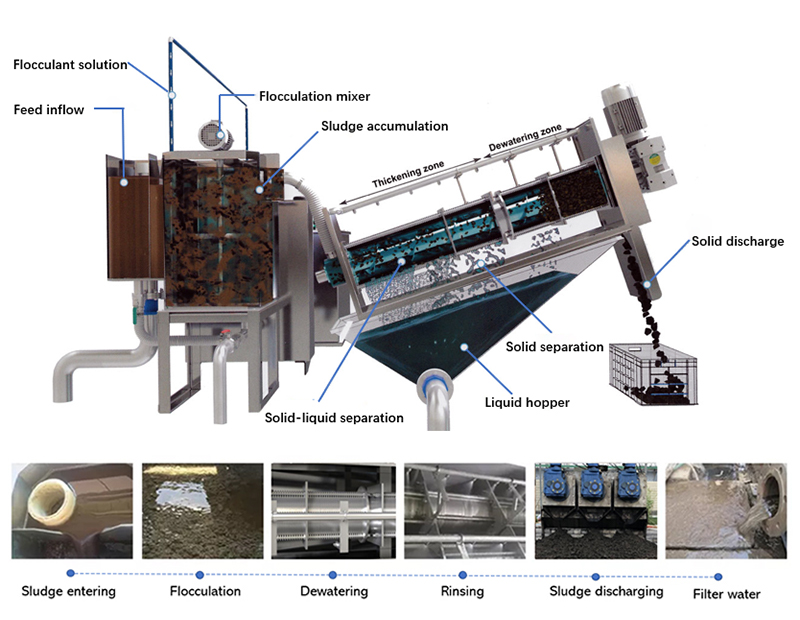

Sludge Dehydrator Process

Before the dewatering process begins, the sludge must be passed through any of the mineral chemicals or organic chemicals, such as coagulants and flocculants. After conditioning the sludge, it is then thickened by dissolved air flotation, gravity belt, thickening drum/spiral drum or centrifuge.

Once the conditioning step is complete, the analysis of the most suitable sludge dewatering technology can begin. The choice of sludge treatment method depends on several factors, including characteristics, volume, time and disposal options available. Common dewatering options are plate and frame filter presses, membrane filter presses, chamber filter presses, belt filter presses, centrifuges and screw presses.

Sludge Dehydrator Model

Model

DL303

DS

capacity kg/h

90--150 kg/h

Sludge capacity m3/h(2-50g/L)

3-45

Spiral diameter mm

¢310*3

Discharge

Distance mm

495

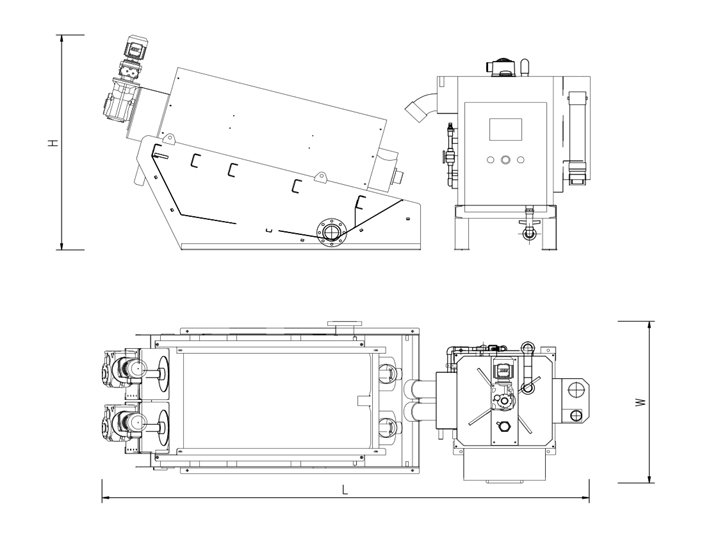

Size L*W*H

mm

3605*1690*1600

Net.Kg

1520

Run Kg

3080

Power

Kw

1.86

Washing Q L/h

120

Sludge Dehydrator Advantages

The body of the sludge dewatering machine is made of 304 stainless steel, which is corrosion-resistant and wear-resistant.

Automated procedures, saving water and electricity, and reducing project costs

Due to the use of low-speed screw extrusion technology, the power consumption is very low. At the same time, it is equipped with an automatic spray system, which avoids clogging and does not require a lot of water to rinse.

The purpose of sludge dewatering is to further reduce the volume of sludge to facilitate subsequent treatment, disposal and utilization. Sludge dewatering unit can reduce processing costs and improve processing efficiency.

Sludge Dehydrator Application

Municipal engineering, wastewater treatment, food and beverage, breeding and slaughtering, oils and starches, petrochemicals, pharmaceuticals, iron and steel metallurgy, textile printing and dyeing, leather, mining, carbon and paper making and other industries.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China